What is Global Low-Lead Pewter Alloy Market?

The Global Low-Lead Pewter Alloy Market is a specialized segment within the broader metal alloys industry, focusing on the production and distribution of pewter alloys with reduced lead content. Pewter, traditionally composed of tin, copper, and lead, has been a popular material for centuries due to its malleability and attractive finish. However, the presence of lead poses health and environmental concerns, prompting a shift towards low-lead alternatives. These low-lead pewter alloys maintain the desirable properties of traditional pewter, such as ease of casting and a lustrous appearance, while significantly reducing the health risks associated with lead exposure. The market for these alloys is driven by increasing regulatory pressures and consumer demand for safer, more sustainable materials. Industries such as decorative arts, fashion, and kitchenware are particularly interested in these alloys, as they offer a safer option without compromising on quality or aesthetic appeal. As awareness of the dangers of lead continues to grow, the demand for low-lead pewter alloys is expected to rise, making this market an important area of focus for manufacturers and consumers alike.

Sn–Sb–Cu, Sn–Bi–Cu, Sn–Sb–Bi in the Global Low-Lead Pewter Alloy Market:

In the Global Low-Lead Pewter Alloy Market, several alloy compositions are gaining prominence due to their unique properties and applications. Among these, Sn–Sb–Cu, Sn–Bi–Cu, and Sn–Sb–Bi alloys stand out. The Sn–Sb–Cu alloy is a combination of tin (Sn), antimony (Sb), and copper (Cu). This alloy is known for its excellent mechanical properties and resistance to corrosion, making it suitable for applications where durability is paramount. The presence of antimony enhances the hardness and strength of the alloy, while copper contributes to its overall toughness. This makes Sn–Sb–Cu alloys ideal for use in decorative items and components that require a robust structure. On the other hand, Sn–Bi–Cu alloys, composed of tin, bismuth (Bi), and copper, offer a different set of advantages. Bismuth is a non-toxic element that serves as an excellent substitute for lead, providing similar properties without the associated health risks. The inclusion of bismuth in the alloy enhances its machinability and reduces its melting point, making it easier to work with in various manufacturing processes. This makes Sn–Bi–Cu alloys particularly attractive for applications in the fashion and kitchenware industries, where intricate designs and ease of production are essential. Lastly, Sn–Sb–Bi alloys combine the benefits of both antimony and bismuth, resulting in a material that is both strong and easy to work with. The combination of these elements provides a balance of hardness, strength, and low melting point, making it versatile for a wide range of applications. This alloy is particularly useful in prototyping and electrical components, where precision and reliability are crucial. The choice between these alloys depends on the specific requirements of the application, such as the need for strength, ease of manufacturing, or non-toxicity. As the demand for low-lead alternatives continues to grow, these alloys offer viable solutions for industries looking to balance performance with safety and environmental considerations.

Decorative Arts, Fashion Accessories, Kitchenware, Electrical Components, Prototyping Making, Others in the Global Low-Lead Pewter Alloy Market:

The Global Low-Lead Pewter Alloy Market finds its applications across various sectors, each benefiting from the unique properties of these alloys. In the realm of Decorative Arts, low-lead pewter alloys are prized for their ability to be easily cast into intricate shapes and designs. Artists and craftsmen appreciate the material's smooth finish and ability to hold fine details, making it ideal for creating sculptures, ornaments, and other decorative items. The reduced lead content ensures that these pieces are safer for both the creators and the end-users, aligning with the growing demand for environmentally friendly and health-conscious products. In the Fashion Accessories industry, low-lead pewter alloys are used to create a wide range of items, including jewelry, belt buckles, and buttons. The alloys' malleability allows designers to experiment with complex shapes and textures, while their durability ensures that the final products can withstand everyday wear and tear. The non-toxic nature of these alloys is particularly important in this sector, as it ensures that the accessories are safe to wear against the skin. Kitchenware is another area where low-lead pewter alloys are making a significant impact. The alloys' resistance to corrosion and tarnishing makes them suitable for items such as utensils, serving dishes, and decorative kitchen items. Consumers are increasingly seeking out kitchenware that is not only functional but also safe and sustainable, and low-lead pewter alloys meet these criteria. In the field of Electrical Components, the alloys' excellent conductivity and resistance to oxidation make them suitable for use in connectors, terminals, and other components. The reduced lead content is particularly important in this sector, as it minimizes the risk of lead contamination in electronic devices. Prototyping Making is another area where low-lead pewter alloys are gaining traction. The alloys' ease of casting and ability to hold fine details make them ideal for creating prototypes and models. Designers and engineers can quickly produce accurate representations of their designs, allowing for efficient testing and iteration. Finally, low-lead pewter alloys are used in various other applications, from model making to the production of small mechanical parts. The versatility and safety of these alloys make them a valuable resource for industries looking to innovate while adhering to stricter health and environmental standards.

Global Low-Lead Pewter Alloy Market Outlook:

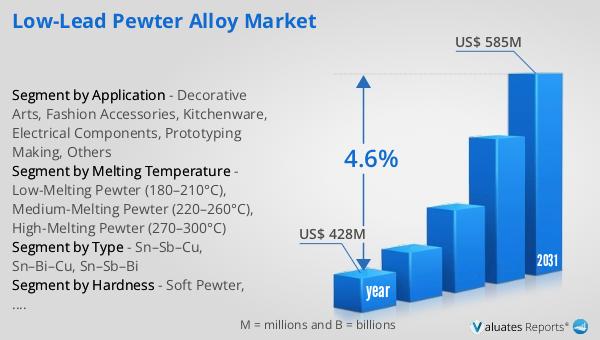

The global market for Low-Lead Pewter Alloy was valued at $428 million in 2024, with projections indicating a growth to $585 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.6% over the forecast period. This upward trend is driven by increasing awareness of the health and environmental risks associated with traditional lead-containing pewter alloys. As regulations become more stringent and consumers demand safer, more sustainable products, the market for low-lead alternatives is expected to expand. Manufacturers are investing in research and development to create alloys that not only meet safety standards but also offer the same aesthetic and functional qualities as traditional pewter. This focus on innovation is likely to drive further growth in the market, as industries such as decorative arts, fashion, and kitchenware continue to seek out materials that align with their sustainability goals. The projected growth of the low-lead pewter alloy market reflects a broader trend towards safer, more environmentally friendly materials across various industries. As the market continues to evolve, companies that prioritize safety and sustainability are likely to see increased demand for their products.

| Report Metric | Details |

| Report Name | Low-Lead Pewter Alloy Market |

| Accounted market size in year | US$ 428 million |

| Forecasted market size in 2031 | US$ 585 million |

| CAGR | 4.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Melting Temperature |

|

| Segment by Hardness |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Belmont Metals (USA), NEY Metals & Alloys (USA), Oster Pewter (USA), Nathan Trotter (USA), William Rowland (UK), DKL Metals (UK), British Tin & Pewter Mills (UK), G.W. Neale (UK), Soudetam (France), Jaytee Alloys (India) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |