What is Global Porous Aluminum Plate Market?

The Global Porous Aluminum Plate Market is an intriguing segment within the broader aluminum industry, characterized by its unique properties and diverse applications. Porous aluminum plates are specialized materials that feature a network of interconnected pores, which can vary in size and distribution. These plates are engineered to offer a combination of lightweight structure, high strength, and excellent thermal and acoustic insulation properties. The global market for these plates is driven by their increasing use in various industries such as construction, automotive, aerospace, and industrial machinery. The demand is fueled by the need for materials that can enhance energy efficiency, reduce weight, and improve overall performance in various applications. As industries continue to innovate and seek sustainable solutions, porous aluminum plates are gaining traction due to their recyclability and environmental benefits. The market is also influenced by technological advancements that allow for the customization of pore structures to meet specific application requirements. Overall, the Global Porous Aluminum Plate Market is poised for growth as it aligns with the global trends of sustainability and efficiency.

Open-Cell Structure, Closed-Cell Structure in the Global Porous Aluminum Plate Market:

In the Global Porous Aluminum Plate Market, the open-cell and closed-cell structures are two fundamental configurations that define the characteristics and applications of porous aluminum plates. Open-cell structures are characterized by interconnected pores that allow fluids and gases to pass through the material. This structure is particularly beneficial in applications requiring filtration, sound absorption, and thermal management. The open-cell design facilitates the flow of air or liquids, making it ideal for use in heat exchangers, filters, and acoustic panels. The interconnected nature of the pores also enhances the material's ability to dissipate heat, which is crucial in high-temperature environments. On the other hand, closed-cell structures consist of isolated pores that do not interconnect. This configuration provides excellent insulation properties, as the trapped air within the cells acts as a barrier to heat and sound. Closed-cell porous aluminum plates are often used in applications where moisture resistance and thermal insulation are critical, such as in building insulation and automotive components. The choice between open-cell and closed-cell structures depends on the specific requirements of the application, including factors such as thermal conductivity, acoustic performance, and mechanical strength. Both structures offer unique advantages and can be tailored to meet the demands of various industries. The versatility of porous aluminum plates, combined with their lightweight and durable nature, makes them a valuable material in the quest for energy efficiency and sustainability. As industries continue to evolve, the ability to customize pore structures will play a significant role in expanding the applications of porous aluminum plates. The ongoing research and development in this field are expected to lead to new innovations and improvements in the performance of these materials. The Global Porous Aluminum Plate Market is thus a dynamic and evolving sector, driven by the need for advanced materials that can meet the challenges of modern industry.

Construction, Automotive, Industrial Machinery, Aerospace & Defense, Others in the Global Porous Aluminum Plate Market:

The usage of porous aluminum plates spans several key industries, each benefiting from the unique properties of this material. In the construction industry, porous aluminum plates are used for their lightweight and durable nature, which makes them ideal for building facades, roofing, and insulation. The material's ability to provide thermal and acoustic insulation helps in creating energy-efficient buildings that meet modern sustainability standards. In the automotive sector, porous aluminum plates are utilized to reduce vehicle weight, thereby improving fuel efficiency and reducing emissions. They are used in components such as heat exchangers, mufflers, and soundproofing panels, where their ability to manage heat and sound is highly valued. The industrial machinery sector benefits from the use of porous aluminum plates in filtration systems, where their open-cell structure allows for effective separation of particles and fluids. This is crucial in processes that require high levels of precision and cleanliness. In the aerospace and defense industries, the lightweight and high-strength properties of porous aluminum plates are leveraged to enhance the performance of aircraft and military vehicles. The material's ability to withstand extreme temperatures and conditions makes it suitable for use in critical components such as heat shields and structural panels. Additionally, the recyclability of aluminum aligns with the industry's focus on sustainability and reducing environmental impact. Beyond these sectors, porous aluminum plates find applications in various other areas, including electronics, where they are used for thermal management in devices, and in the medical field, where their biocompatibility and structural properties are utilized in implants and prosthetics. The versatility and adaptability of porous aluminum plates make them a valuable material across a wide range of applications, contributing to advancements in technology and industry.

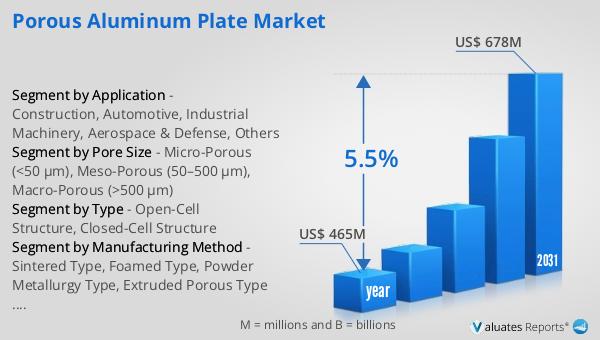

Global Porous Aluminum Plate Market Outlook:

The global market for porous aluminum plates was valued at $465 million in 2024, and it is anticipated to grow significantly, reaching an estimated size of $678 million by 2031. This growth represents a compound annual growth rate (CAGR) of 5.5% over the forecast period. The increasing demand for lightweight, durable, and efficient materials across various industries is a key driver of this market expansion. As industries such as construction, automotive, aerospace, and industrial machinery continue to seek materials that offer enhanced performance and sustainability, porous aluminum plates are becoming increasingly popular. The market's growth is also supported by technological advancements that enable the customization of pore structures to meet specific application needs. This ability to tailor the material's properties enhances its appeal across different sectors, further fueling market demand. The projected growth of the Global Porous Aluminum Plate Market reflects the broader trends of innovation and sustainability that are shaping the future of materials science. As industries continue to evolve and adapt to changing environmental and economic conditions, the demand for advanced materials like porous aluminum plates is expected to remain strong.

| Report Metric | Details |

| Report Name | Porous Aluminum Plate Market |

| Accounted market size in year | US$ 465 million |

| Forecasted market size in 2031 | US$ 678 million |

| CAGR | 5.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Manufacturing Method |

|

| Segment by Pore Size |

|

| Segment by Alloy Composition |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Portec (Switzerland), Exxentis (Switzerland), ALWA (Germany), Alupor (Russia), HAVEL Metal Foam (Germany), Beihai Composite Materials Group (China), Henan Chalco Aluminium (China), Shanxi Putai Aluminum Foam (China), Pohltec Metalfoam (Germany), Aluinvent (Hungary) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |