What is Global P-tert-octylphenol Formaldehyde Tackifier Resin Market?

The Global P-tert-octylphenol Formaldehyde Tackifier Resin Market is a specialized segment within the broader chemical industry, focusing on the production and distribution of tackifier resins. These resins are essential components in adhesive formulations, providing the necessary stickiness or tack to ensure that adhesives bond effectively to surfaces. P-tert-octylphenol formaldehyde tackifier resins are particularly valued for their excellent thermal stability, compatibility with various polymers, and resistance to aging and oxidation. These properties make them suitable for a wide range of applications, including in the automotive, construction, and packaging industries. The market for these resins is driven by the increasing demand for high-performance adhesives that can withstand harsh environmental conditions and maintain their adhesive properties over time. As industries continue to innovate and develop new products, the need for reliable and efficient tackifier resins is expected to grow, further fueling the expansion of this market segment. The global reach of this market indicates its importance in various industrial applications worldwide, highlighting the critical role these resins play in modern manufacturing and production processes.

Softening Point≥90°C, Softening Point≥100°C in the Global P-tert-octylphenol Formaldehyde Tackifier Resin Market:

The Global P-tert-octylphenol Formaldehyde Tackifier Resin Market is characterized by products with varying softening points, notably those with softening points of ≥90°C and ≥100°C. These softening points are crucial as they determine the temperature at which the resin transitions from a solid to a more pliable state, affecting its performance in adhesive applications. Resins with a softening point of ≥90°C are typically used in applications where moderate heat resistance is required. They provide a balance between flexibility and thermal stability, making them suitable for use in environments where temperatures do not exceed this threshold. These resins are often employed in the production of pressure-sensitive adhesives, which are used in labels, tapes, and other applications where a strong initial tack is necessary. On the other hand, resins with a softening point of ≥100°C are designed for more demanding applications where higher thermal resistance is needed. These resins are ideal for use in hot-melt adhesives, which are applied in a molten state and solidify upon cooling. The higher softening point ensures that the adhesive maintains its integrity and performance even in high-temperature environments, such as in automotive or industrial settings. The choice between these two types of resins depends largely on the specific requirements of the application, including the expected temperature range and the desired adhesive properties. In addition to temperature resistance, other factors such as compatibility with different polymers, aging resistance, and color stability also play a role in determining the suitability of a particular resin for a given application. Manufacturers in the Global P-tert-octylphenol Formaldehyde Tackifier Resin Market must carefully consider these factors when developing and marketing their products to ensure they meet the diverse needs of their customers. As industries continue to evolve and demand more specialized adhesive solutions, the development of resins with tailored softening points and other performance characteristics will be essential to maintaining competitiveness in this market.

Tires, Rubber Products, Others in the Global P-tert-octylphenol Formaldehyde Tackifier Resin Market:

The usage of Global P-tert-octylphenol Formaldehyde Tackifier Resin Market extends across various sectors, including tires, rubber products, and other applications. In the tire industry, these resins are used to enhance the adhesive properties of rubber compounds, ensuring that the different layers of a tire bond effectively during the manufacturing process. This is crucial for maintaining the structural integrity and performance of the tire, particularly in terms of grip and durability. The resins help improve the tackiness of the rubber, allowing for better adhesion between the tread and the underlying layers, which is essential for the tire's overall performance and safety. In the production of rubber products, P-tert-octylphenol formaldehyde tackifier resins are used to improve the bonding of rubber to various substrates, such as metals and textiles. This is important in the manufacture of products like hoses, belts, and seals, where strong adhesion is necessary to ensure the product's functionality and longevity. The resins provide the necessary tack to ensure that the rubber adheres effectively to these substrates, even under challenging conditions such as high temperatures or exposure to chemicals. Beyond tires and rubber products, these resins find applications in other areas where strong adhesive properties are required. For example, they are used in the production of adhesives for the construction industry, where they help ensure that materials bond effectively and maintain their integrity over time. They are also used in the packaging industry, where they provide the necessary tack for sealing boxes and other packaging materials. The versatility of P-tert-octylphenol formaldehyde tackifier resins makes them an essential component in a wide range of industrial applications, highlighting their importance in modern manufacturing processes. As industries continue to demand more specialized and high-performance adhesive solutions, the role of these resins in ensuring the success of various products and applications will only continue to grow.

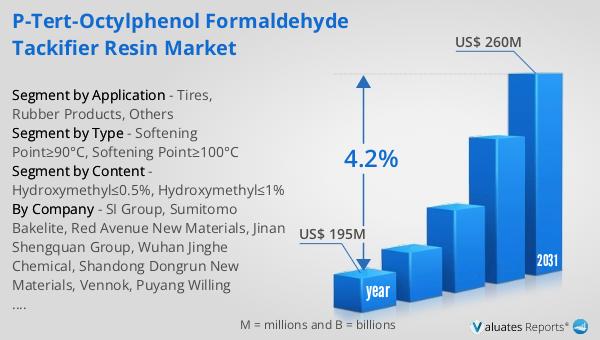

Global P-tert-octylphenol Formaldehyde Tackifier Resin Market Outlook:

The global market for P-tert-octylphenol Formaldehyde Tackifier Resin was valued at approximately $195 million in 2024. This market is anticipated to expand, reaching an estimated size of $260 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.2% over the forecast period. This upward trend is indicative of the increasing demand for high-performance adhesives across various industries, driven by the need for products that offer superior bonding capabilities and can withstand harsh environmental conditions. The projected growth of this market underscores the importance of P-tert-octylphenol formaldehyde tackifier resins in modern manufacturing processes, as industries continue to seek out materials that enhance the performance and durability of their products. The steady growth rate also reflects the ongoing innovation and development within the adhesive industry, as manufacturers strive to meet the evolving needs of their customers. As the market continues to expand, companies operating within this space will need to focus on developing new and improved resin formulations that offer enhanced performance characteristics, such as increased thermal stability, improved compatibility with various polymers, and greater resistance to aging and oxidation. By doing so, they can ensure that they remain competitive in this dynamic and rapidly evolving market.

| Report Metric | Details |

| Report Name | P-tert-octylphenol Formaldehyde Tackifier Resin Market |

| Accounted market size in year | US$ 195 million |

| Forecasted market size in 2031 | US$ 260 million |

| CAGR | 4.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Content |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SI Group, Sumitomo Bakelite, Red Avenue New Materials, Jinan Shengquan Group, Wuhan Jinghe Chemical, Shandong Dongrun New Materials, Vennok, Puyang Willing Chemicals |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |