What is Global Molds for Precast Concrete Culverts Market?

The Global Molds for Precast Concrete Culverts Market is a specialized segment within the construction industry that focuses on the production and use of molds designed for creating precast concrete culverts. These culverts are essential components in infrastructure projects, serving as tunnels or channels that allow water to flow under roads, railways, or embankments. The molds used in this market are crucial because they determine the shape, size, and quality of the culverts produced. Typically made from durable materials like steel or fiberglass, these molds must withstand the pressures of concrete casting and ensure a smooth finish for the final product. The market for these molds is driven by the increasing demand for efficient and durable infrastructure solutions worldwide. As urbanization and industrialization continue to expand, the need for reliable drainage and water management systems grows, thereby boosting the demand for precast concrete culverts and, consequently, the molds used to create them. This market is characterized by innovation and technological advancements, as manufacturers strive to produce molds that are not only cost-effective but also environmentally friendly and easy to use.

Single-Cell, Multi-Cell in the Global Molds for Precast Concrete Culverts Market:

In the Global Molds for Precast Concrete Culverts Market, the distinction between single-cell and multi-cell molds is significant, as it directly impacts the design and functionality of the culverts produced. Single-cell molds are designed to create culverts with a single, continuous passageway. These are typically used in applications where a straightforward, unobstructed flow of water or other materials is required. The simplicity of single-cell molds makes them a cost-effective choice for many projects, as they require less material and labor to produce. However, their application is somewhat limited to scenarios where the volume of flow is relatively low or where space constraints do not allow for larger structures. On the other hand, multi-cell molds are used to create culverts with multiple passageways or cells. These are particularly useful in situations where a higher volume of flow needs to be managed, or where the distribution of flow is necessary to prevent erosion or flooding. Multi-cell culverts are often employed in larger infrastructure projects, such as major highways or railway systems, where the demands on drainage systems are more complex. The design of multi-cell molds is inherently more complex, requiring precise engineering to ensure that each cell is properly aligned and that the overall structure can withstand the pressures of both the casting process and the operational environment. The choice between single-cell and multi-cell molds is influenced by several factors, including the specific requirements of the project, budget constraints, and environmental considerations. For instance, in areas prone to heavy rainfall or flooding, multi-cell culverts may be preferred due to their ability to handle larger volumes of water and distribute it more evenly. Conversely, in arid regions where water flow is minimal, single-cell culverts may suffice. Additionally, the decision may also be guided by regulatory standards and guidelines, which can vary significantly from one region to another. Manufacturers in this market are continually innovating to improve the efficiency and effectiveness of both single-cell and multi-cell molds. Advances in materials science have led to the development of molds that are lighter, more durable, and easier to handle, reducing the overall cost and time required for installation. Furthermore, the integration of digital technologies, such as computer-aided design (CAD) and 3D printing, has enabled more precise and customizable mold designs, allowing for greater flexibility in meeting the diverse needs of infrastructure projects around the world. As the demand for sustainable and resilient infrastructure continues to grow, the Global Molds for Precast Concrete Culverts Market is poised to play a critical role in shaping the future of construction and urban development.

Highway and Road Construction, Railway and Metro Projects, Irrigation and Drainage Systems, Others in the Global Molds for Precast Concrete Culverts Market:

The usage of Global Molds for Precast Concrete Culverts Market spans several key areas, each with its unique requirements and challenges. In highway and road construction, precast concrete culverts are essential for managing water flow and preventing erosion. They are used to channel water under roads, ensuring that the infrastructure remains stable and safe for use. The molds used in this context must be robust and capable of producing culverts that can withstand the pressures of heavy traffic and environmental factors. In railway and metro projects, the need for reliable drainage systems is equally critical. Precast concrete culverts are used to manage water flow around tracks and stations, preventing flooding and ensuring the safe operation of trains. The molds used in these projects must be precise and capable of producing culverts that fit seamlessly into the existing infrastructure. In irrigation and drainage systems, precast concrete culverts play a vital role in directing water to where it is needed most. They are used to channel water from rivers and reservoirs to agricultural fields, ensuring that crops receive the necessary hydration. The molds used in this context must be versatile and capable of producing culverts in a variety of shapes and sizes to accommodate different terrains and water flow requirements. Finally, in other areas such as industrial and commercial construction, precast concrete culverts are used to manage stormwater and wastewater. They are essential for preventing flooding and ensuring that water is directed away from buildings and other structures. The molds used in these projects must be durable and capable of producing culverts that can withstand the corrosive effects of wastewater and other chemicals. Overall, the Global Molds for Precast Concrete Culverts Market plays a crucial role in ensuring the safety and efficiency of infrastructure projects around the world.

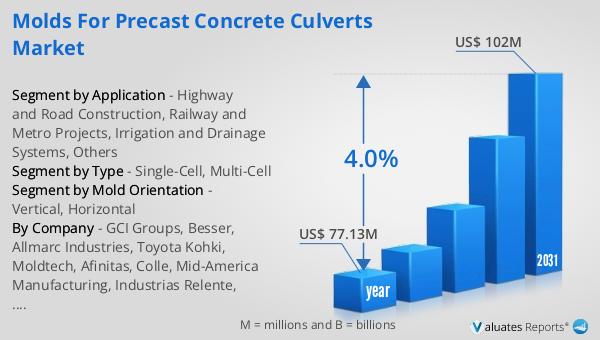

Global Molds for Precast Concrete Culverts Market Outlook:

The global market for molds used in the production of precast concrete culverts was valued at approximately $77.13 million in 2024. This market is anticipated to experience growth, reaching an estimated value of $102 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.0% over the forecast period. This upward trend is indicative of the increasing demand for efficient and durable infrastructure solutions across the globe. As urbanization and industrialization continue to expand, the need for reliable drainage and water management systems becomes more pronounced, driving the demand for precast concrete culverts and the molds used to create them. The market's growth is also fueled by advancements in technology and materials, which have led to the development of more efficient and cost-effective molds. These innovations have made it possible to produce high-quality culverts that meet the diverse needs of infrastructure projects worldwide. Additionally, the market is characterized by a focus on sustainability, with manufacturers striving to create molds that are environmentally friendly and easy to use. As a result, the Global Molds for Precast Concrete Culverts Market is poised to play a critical role in shaping the future of construction and urban development.

| Report Metric | Details |

| Report Name | Molds for Precast Concrete Culverts Market |

| Accounted market size in year | US$ 77.13 million |

| Forecasted market size in 2031 | US$ 102 million |

| CAGR | 4.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Mold Orientation |

|

| Segment by Application |

|

| By Region |

|

| By Company | GCI Groups, Besser, Allmarc Industries, Toyota Kohki, Moldtech, Afinitas, Colle, Mid-America Manufacturing, Industrias Relente, Norwalk Precast Molds, Dema Formwork, Cleco Manufacturing, LTP Engineering, Jiangsu Tangchen Machinery Equipment Manufacturing, Dezhou Haitian Electromechanical Technology, UNIcrane Machinery, Qingdao Hicorp Group, Gaotang County Dingli Construction Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |