What is Global Butyltin Mercaptide Stabilizers Market?

The Global Butyltin Mercaptide Stabilizers Market is a specialized segment within the broader chemical industry, focusing on the production and distribution of butyltin mercaptide stabilizers. These stabilizers are essential additives used primarily in the manufacturing of polyvinyl chloride (PVC) products. They play a crucial role in enhancing the thermal stability of PVC, which is vital for maintaining the material's integrity and performance under various conditions. The market for these stabilizers is driven by the growing demand for PVC products across multiple industries, including construction, automotive, and packaging. As industries continue to seek materials that offer durability and cost-effectiveness, the demand for efficient stabilizers like butyltin mercaptide is expected to rise. This market is characterized by technological advancements and innovations aimed at improving the efficiency and environmental compatibility of these stabilizers. Companies operating in this market are continually investing in research and development to meet the evolving needs of their customers and comply with stringent environmental regulations. The global reach of this market underscores its importance in supporting the production of high-quality PVC products worldwide.

Purity≥98.0%, Purity≥99.0% in the Global Butyltin Mercaptide Stabilizers Market:

In the Global Butyltin Mercaptide Stabilizers Market, the purity levels of the stabilizers, such as Purity≥98.0% and Purity≥99.0%, are critical factors that influence their performance and application. Purity levels indicate the concentration of the active stabilizing compound within the product, with higher purity levels generally translating to more effective stabilization properties. Stabilizers with a purity of ≥98.0% are commonly used in applications where standard thermal stability is required. These stabilizers are effective in maintaining the structural integrity of PVC products under moderate thermal conditions, making them suitable for a wide range of general-purpose applications. On the other hand, stabilizers with a purity of ≥99.0% are designed for more demanding applications where superior thermal stability is essential. These high-purity stabilizers are often used in the production of PVC products that are exposed to extreme temperatures or require enhanced durability. The choice between these purity levels depends on the specific requirements of the end-use application, as well as cost considerations. Manufacturers in the Global Butyltin Mercaptide Stabilizers Market must carefully balance the need for high-performance stabilizers with the economic constraints of their customers. As a result, they offer a range of products with varying purity levels to cater to different market segments. The production of high-purity stabilizers involves advanced manufacturing processes and stringent quality control measures to ensure consistency and reliability. This requires significant investment in technology and expertise, which can impact the overall cost of the product. However, the benefits of using high-purity stabilizers, such as improved product performance and longer service life, often justify the higher cost for many applications. In addition to thermal stability, the purity of butyltin mercaptide stabilizers can also affect other properties of PVC products, such as clarity, color, and mechanical strength. High-purity stabilizers are less likely to introduce impurities or discoloration, which is particularly important in applications where aesthetic qualities are a priority. Furthermore, the use of high-purity stabilizers can enhance the mechanical properties of PVC products, making them more resistant to wear and tear. This is especially beneficial in applications where the products are subjected to mechanical stress or harsh environmental conditions. The demand for high-purity butyltin mercaptide stabilizers is also influenced by regulatory requirements and environmental considerations. As industries strive to reduce their environmental footprint, there is a growing emphasis on using stabilizers that are not only effective but also environmentally friendly. High-purity stabilizers are often associated with lower levels of volatile organic compounds (VOCs) and other harmful emissions, making them a preferred choice for environmentally conscious manufacturers. In conclusion, the purity levels of butyltin mercaptide stabilizers play a crucial role in determining their suitability for various applications. Manufacturers in the Global Butyltin Mercaptide Stabilizers Market must navigate the complex interplay of performance, cost, and environmental considerations to provide products that meet the diverse needs of their customers. By offering a range of purity levels, they can cater to different market segments and support the production of high-quality PVC products across various industries.

Pipes, Profiles, Sheets, Others in the Global Butyltin Mercaptide Stabilizers Market:

The Global Butyltin Mercaptide Stabilizers Market finds its applications in several key areas, including pipes, profiles, sheets, and others. In the production of PVC pipes, butyltin mercaptide stabilizers are essential for ensuring the pipes' thermal stability and durability. PVC pipes are widely used in plumbing, irrigation, and drainage systems due to their cost-effectiveness and resistance to corrosion. The stabilizers help maintain the structural integrity of the pipes under varying temperature conditions, preventing deformation and extending their service life. In the profiles segment, which includes products like window frames and door profiles, butyltin mercaptide stabilizers play a crucial role in maintaining the aesthetic and functional properties of the profiles. These stabilizers ensure that the profiles retain their shape, color, and mechanical strength over time, even when exposed to harsh environmental conditions. This is particularly important in the construction industry, where the longevity and appearance of building materials are critical considerations. In the production of PVC sheets, which are used in applications ranging from packaging to construction, butyltin mercaptide stabilizers contribute to the sheets' thermal stability and mechanical properties. The stabilizers help prevent warping and discoloration, ensuring that the sheets maintain their intended appearance and functionality. This is especially important in applications where the sheets are exposed to high temperatures or mechanical stress. Beyond these specific applications, butyltin mercaptide stabilizers are also used in a variety of other PVC products, including cables, films, and coatings. In each of these applications, the stabilizers play a vital role in enhancing the thermal stability and overall performance of the products. The versatility of butyltin mercaptide stabilizers makes them a valuable component in the production of a wide range of PVC products, supporting industries such as construction, automotive, and packaging. The use of butyltin mercaptide stabilizers in these applications is driven by the need for materials that offer a balance of performance, cost-effectiveness, and environmental compatibility. As industries continue to seek sustainable solutions, the demand for efficient and environmentally friendly stabilizers is expected to grow. Manufacturers in the Global Butyltin Mercaptide Stabilizers Market are continually innovating to meet these demands, developing products that offer enhanced performance while minimizing environmental impact. In summary, the Global Butyltin Mercaptide Stabilizers Market plays a critical role in supporting the production of high-quality PVC products across various industries. By providing thermal stability and enhancing the performance of PVC products, these stabilizers contribute to the durability and functionality of pipes, profiles, sheets, and other applications. As industries continue to evolve and prioritize sustainability, the demand for efficient and environmentally friendly stabilizers is likely to increase, driving further innovation and growth in this market.

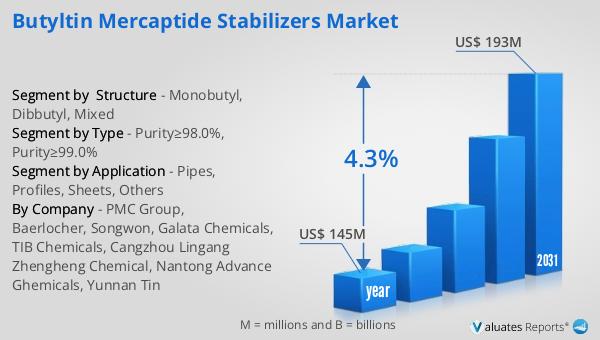

Global Butyltin Mercaptide Stabilizers Market Outlook:

The global market for Butyltin Mercaptide Stabilizers was valued at $145 million in 2024, with projections indicating it will grow to a revised size of $193 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.3% over the forecast period. This upward trajectory highlights the increasing demand for these stabilizers, driven by their critical role in enhancing the thermal stability of PVC products. As industries such as construction, automotive, and packaging continue to expand, the need for durable and cost-effective materials like PVC is on the rise. Butyltin mercaptide stabilizers are essential in ensuring the performance and longevity of these materials, making them a vital component in the production process. The market's growth is also supported by ongoing technological advancements and innovations aimed at improving the efficiency and environmental compatibility of these stabilizers. Companies operating in this market are investing in research and development to meet the evolving needs of their customers and comply with stringent environmental regulations. As a result, the Global Butyltin Mercaptide Stabilizers Market is poised for continued growth, driven by the increasing demand for high-quality PVC products and the ongoing pursuit of sustainable solutions.

| Report Metric | Details |

| Report Name | Butyltin Mercaptide Stabilizers Market |

| Accounted market size in year | US$ 145 million |

| Forecasted market size in 2031 | US$ 193 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Structure |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | PMC Group, Baerlocher, Songwon, Galata Chemicals, TIB Chemicals, Cangzhou Lingang Zhengheng Chemical, Nantong Advance Ghemicals, Yunnan Tin |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |