What is Medicinal Tubular Glass Bottles - Global Market?

Medicinal tubular glass bottles are a crucial component in the global healthcare and pharmaceutical industries. These bottles are specifically designed to store and transport various medicinal products, ensuring their safety and efficacy. Made from high-quality glass, these bottles offer excellent chemical resistance, preventing any interaction between the container and its contents. This is particularly important for preserving the integrity of sensitive medications and vaccines. The global market for medicinal tubular glass bottles is driven by the increasing demand for safe and reliable packaging solutions in the pharmaceutical sector. As healthcare needs continue to grow worldwide, so does the need for effective packaging that can maintain the stability and sterility of medicinal products. These bottles are available in various sizes and shapes, catering to different requirements of pharmaceutical companies, hospitals, and laboratories. The market is also influenced by advancements in glass manufacturing technologies, which enhance the durability and functionality of these bottles. Overall, medicinal tubular glass bottles play a vital role in the global healthcare system, ensuring that medicines are delivered safely from manufacturers to end-users.

Borosilicate Glass, Soda-lime-silica Glass in the Medicinal Tubular Glass Bottles - Global Market:

Borosilicate glass and soda-lime-silica glass are two primary types of glass used in the production of medicinal tubular glass bottles, each offering distinct properties that make them suitable for specific applications. Borosilicate glass is renowned for its superior thermal and chemical resistance, making it an ideal choice for storing sensitive pharmaceutical products that require stability under varying temperature conditions. This type of glass is composed of silica and boron trioxide, which gives it a low coefficient of thermal expansion, allowing it to withstand sudden temperature changes without cracking. This property is particularly beneficial in laboratory settings where sterilization processes involve high temperatures. Additionally, borosilicate glass is highly resistant to chemical corrosion, ensuring that the contents of the bottle remain uncontaminated over time. On the other hand, soda-lime-silica glass is the most common type of glass used in the production of medicinal bottles due to its cost-effectiveness and versatility. Composed mainly of silica, soda, and lime, this glass type offers adequate chemical resistance for many pharmaceutical applications, although it is not as robust as borosilicate glass in terms of thermal stability. Soda-lime-silica glass is often used for products that do not require extreme temperature resistance, making it suitable for a wide range of medicinal products. The choice between borosilicate and soda-lime-silica glass depends largely on the specific requirements of the pharmaceutical product being stored, including factors such as chemical composition, storage conditions, and regulatory standards. Both types of glass are integral to the medicinal tubular glass bottles market, providing essential solutions for the safe storage and transportation of pharmaceutical products worldwide. As the demand for pharmaceutical products continues to rise, the need for high-quality glass packaging solutions remains critical, driving innovation and development in the glass manufacturing industry.

Hospital, Laboratory, Pharmaceutical Company, Others in the Medicinal Tubular Glass Bottles - Global Market:

Medicinal tubular glass bottles are extensively used across various sectors, including hospitals, laboratories, pharmaceutical companies, and other healthcare-related fields, due to their reliability and safety in storing medicinal products. In hospitals, these glass bottles are essential for storing a wide range of medications, including liquid drugs, vaccines, and intravenous solutions. Their ability to maintain the sterility and integrity of the contents makes them indispensable in hospital pharmacies and wards, where patient safety is paramount. The transparency of glass also allows healthcare professionals to easily monitor the contents, ensuring accurate dosage and administration. In laboratory settings, medicinal tubular glass bottles are used for storing reagents, samples, and other chemical substances. The chemical resistance of glass ensures that the contents remain uncontaminated, which is crucial for conducting accurate experiments and research. Laboratories often require glass bottles that can withstand high temperatures during sterilization processes, making borosilicate glass a preferred choice in these environments. Pharmaceutical companies rely heavily on medicinal tubular glass bottles for packaging their products. These bottles provide a secure and stable environment for a wide range of pharmaceutical formulations, from liquid medications to injectable drugs. The choice of glass type, whether borosilicate or soda-lime-silica, depends on the specific requirements of the product, including its chemical properties and storage conditions. Additionally, the global distribution of pharmaceutical products necessitates packaging that can withstand transportation and handling, further highlighting the importance of durable glass bottles. Beyond these primary sectors, medicinal tubular glass bottles are also used in other areas such as veterinary medicine, research institutions, and even in some consumer health products. Their versatility and reliability make them a preferred choice for any application that requires safe and effective storage of medicinal substances. As the healthcare industry continues to evolve, the demand for high-quality glass packaging solutions remains strong, underscoring the critical role that medicinal tubular glass bottles play in ensuring the safety and efficacy of medical products worldwide.

Medicinal Tubular Glass Bottles - Global Market Outlook:

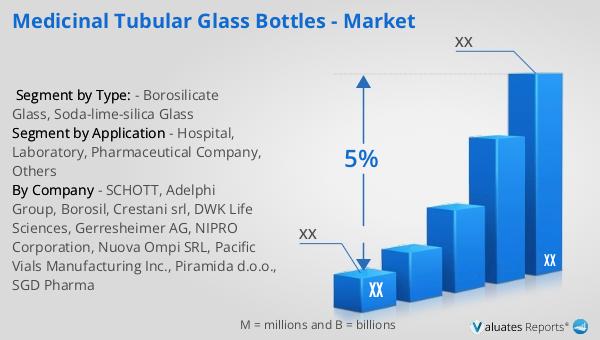

The outlook for the medicinal tubular glass bottles market is closely tied to the broader trends in the global pharmaceutical industry. In 2022, the global pharmaceutical market was valued at approximately 1,475 billion USD, with expectations of a steady growth rate of 5% annually over the next six years. This growth is driven by factors such as an aging population, increasing prevalence of chronic diseases, and advancements in drug development and delivery systems. In comparison, the chemical drug market, a significant segment of the pharmaceutical industry, saw an increase from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This growth trajectory highlights the expanding demand for pharmaceutical products, which in turn fuels the need for reliable packaging solutions like medicinal tubular glass bottles. As pharmaceutical companies continue to innovate and develop new treatments, the importance of high-quality packaging that ensures the safety and efficacy of these products becomes increasingly critical. The medicinal tubular glass bottles market is poised to benefit from these trends, as it provides essential solutions for the storage and transportation of a wide range of pharmaceutical products. The ongoing advancements in glass manufacturing technologies further enhance the capabilities of these bottles, making them an indispensable component of the global healthcare supply chain.

| Report Metric | Details |

| Report Name | Medicinal Tubular Glass Bottles - Market |

| CAGR | 5% |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | SCHOTT, Adelphi Group, Borosil, Crestani srl, DWK Life Sciences, Gerresheimer AG, NIPRO Corporation, Nuova Ompi SRL, Pacific Vials Manufacturing Inc., Piramida d.o.o., SGD Pharma |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |