What is Global Basalt Fiber High Temperature Filter Bags Market?

The Global Basalt Fiber High Temperature Filter Bags Market is a specialized segment within the industrial filtration industry, focusing on the use of basalt fiber materials to create filter bags capable of withstanding high temperatures. Basalt fiber, derived from volcanic rock, is known for its excellent thermal stability, high tensile strength, and resistance to chemical corrosion, making it an ideal material for high-temperature filtration applications. These filter bags are used in various industries where processes involve high temperatures and require efficient filtration to maintain air quality and protect equipment. The market for these filter bags is driven by the increasing demand for durable and efficient filtration solutions in industries such as metallurgy, chemical processing, and cement manufacturing. As industries continue to seek materials that can withstand harsh operating conditions while maintaining performance, the demand for basalt fiber high-temperature filter bags is expected to grow. This market is characterized by technological advancements in material science, leading to improved performance and cost-effectiveness of basalt fiber products. The global market is also influenced by environmental regulations that require industries to control emissions and improve air quality, further driving the adoption of high-performance filtration solutions.

Plain Weave, Twill Weave, Satin Finish in the Global Basalt Fiber High Temperature Filter Bags Market:

In the Global Basalt Fiber High Temperature Filter Bags Market, different weaving techniques are employed to enhance the performance and durability of the filter bags. Plain weave, twill weave, and satin finish are three common weaving patterns used in the production of these filter bags, each offering unique characteristics and benefits. Plain weave is the simplest and most common weaving pattern, where the warp and weft threads cross each other alternately. This pattern provides a balanced structure with uniform strength and stability, making it suitable for general-purpose filtration applications. The plain weave offers good dimensional stability and is relatively easy to produce, making it a cost-effective option for many industries. Twill weave, on the other hand, is characterized by a diagonal rib pattern created by the interlacing of warp and weft threads. This pattern provides enhanced flexibility and drapability, allowing the filter bags to conform to complex shapes and surfaces. Twill weave also offers improved abrasion resistance and strength compared to plain weave, making it ideal for applications where the filter bags are subjected to mechanical stress and wear. The satin finish is a more complex weaving pattern that creates a smooth and lustrous surface on the filter bags. This pattern is achieved by floating the warp or weft threads over multiple threads before interlacing, resulting in a fabric with a high sheen and a soft hand feel. The satin finish offers excellent resistance to abrasion and chemical attack, making it suitable for demanding applications where the filter bags are exposed to harsh environments. Each of these weaving patterns plays a crucial role in the performance and longevity of basalt fiber high-temperature filter bags, allowing manufacturers to tailor their products to meet the specific needs of different industries. The choice of weaving pattern depends on factors such as the operating conditions, the nature of the particles being filtered, and the desired balance between strength, flexibility, and cost. As the demand for high-performance filtration solutions continues to grow, advancements in weaving technology and material science are expected to further enhance the capabilities of basalt fiber filter bags, providing industries with more efficient and durable options for their filtration needs.

Machinery, Metallurgy, Chemical, Cement, Other in the Global Basalt Fiber High Temperature Filter Bags Market:

The usage of Global Basalt Fiber High Temperature Filter Bags Market spans across various industries, each with its unique requirements and challenges. In the machinery industry, these filter bags are used to protect equipment from dust and particulate matter generated during manufacturing processes. The high-temperature resistance of basalt fiber makes these filter bags ideal for use in environments where machinery operates at elevated temperatures, ensuring the longevity and efficiency of the equipment. In the metallurgy industry, basalt fiber filter bags are employed in processes such as smelting and refining, where high temperatures and corrosive environments are common. These filter bags help in capturing fine metal particles and dust, preventing them from escaping into the atmosphere and ensuring compliance with environmental regulations. The chemical industry also benefits from the use of basalt fiber high-temperature filter bags, particularly in processes involving the handling of aggressive chemicals and high-temperature reactions. The chemical resistance and thermal stability of basalt fiber make these filter bags suitable for use in harsh chemical environments, where they help in maintaining air quality and protecting sensitive equipment. In the cement industry, basalt fiber filter bags are used in kilns and other high-temperature processes to capture dust and particulate matter generated during cement production. The durability and heat resistance of basalt fiber ensure that these filter bags can withstand the harsh conditions of cement manufacturing, contributing to improved air quality and reduced emissions. Other industries, such as power generation and waste incineration, also utilize basalt fiber high-temperature filter bags to manage emissions and protect equipment from high-temperature gases and particulates. The versatility and performance of basalt fiber make it a preferred choice for industries seeking reliable and efficient filtration solutions in challenging environments. As industries continue to prioritize sustainability and environmental compliance, the demand for high-performance filtration solutions like basalt fiber high-temperature filter bags is expected to grow, driving innovation and advancements in this market.

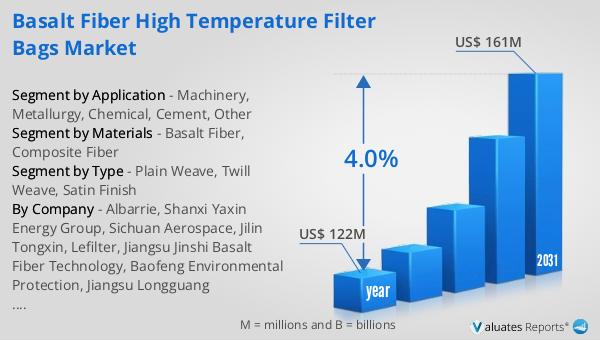

Global Basalt Fiber High Temperature Filter Bags Market Outlook:

The global market for Basalt Fiber High Temperature Filter Bags was valued at $122 million in 2024 and is anticipated to expand to a revised size of $161 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.0% during the forecast period. This growth trajectory underscores the increasing demand for high-performance filtration solutions across various industries. The market's expansion is driven by the need for materials that can withstand extreme temperatures and harsh operating conditions while maintaining efficiency and durability. Basalt fiber, known for its exceptional thermal stability and resistance to chemical corrosion, is becoming a material of choice for industries seeking to enhance their filtration processes. The projected growth in the market is also influenced by stringent environmental regulations that require industries to control emissions and improve air quality. As industries continue to seek innovative solutions to meet these regulatory requirements, the demand for basalt fiber high-temperature filter bags is expected to rise. This market outlook highlights the potential for growth and innovation in the basalt fiber filtration industry, as manufacturers and industries work together to develop more efficient and sustainable filtration solutions. The increasing adoption of basalt fiber high-temperature filter bags across various sectors is a testament to the material's versatility and performance, positioning it as a key player in the future of industrial filtration.

| Report Metric | Details |

| Report Name | Basalt Fiber High Temperature Filter Bags Market |

| Accounted market size in year | US$ 122 million |

| Forecasted market size in 2031 | US$ 161 million |

| CAGR | 4.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Materials |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Albarrie, Shanxi Yaxin Energy Group, Sichuan Aerospace, Jilin Tongxin, Lefilter, Jiangsu Jinshi Basalt Fiber Technology, Baofeng Environmental Protection, Jiangsu Longguang Environmental Protection Technology, SFFILTECH, Anhui Shiqing Environmental Protection Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |