What is Global Spiral Blade Drilling Machine Market?

The Global Spiral Blade Drilling Machine Market refers to the worldwide industry focused on the production, distribution, and utilization of drilling machines equipped with spiral blades. These machines are essential in various sectors, including construction, mining, oil and gas, and infrastructure development, due to their efficiency in drilling through different types of soil and rock. The market encompasses a range of products, from small, portable units to large, industrial-grade machines, catering to diverse drilling needs. The demand for these machines is driven by the ongoing expansion of infrastructure projects, the need for resource extraction, and advancements in drilling technology that enhance operational efficiency and safety. As industries continue to grow and evolve, the Global Spiral Blade Drilling Machine Market is expected to see sustained demand, driven by the need for reliable and efficient drilling solutions.

Long Spiral Drilling Machine, Short Spiral Drilling Machine in the Global Spiral Blade Drilling Machine Market:

Long Spiral Drilling Machines and Short Spiral Drilling Machines are two primary types of equipment within the Global Spiral Blade Drilling Machine Market, each serving distinct purposes based on their design and capabilities. Long Spiral Drilling Machines are typically used for deep drilling applications. They are equipped with extended spiral blades that allow them to penetrate deeper into the earth, making them ideal for projects that require reaching significant depths, such as deep foundation work, geothermal energy extraction, and large-scale mining operations. These machines are designed to handle tough drilling conditions and can operate efficiently in various soil and rock types. Their robust construction and advanced features, such as automated controls and real-time monitoring systems, enhance their performance and reliability, making them a preferred choice for complex and demanding drilling tasks. On the other hand, Short Spiral Drilling Machines are designed for shallower drilling applications. They are equipped with shorter spiral blades, which make them more suitable for projects that do not require deep penetration, such as residential construction, small-scale infrastructure projects, and certain types of mining activities. These machines are generally more compact and easier to maneuver, making them ideal for use in confined spaces or areas with limited access. Despite their smaller size, Short Spiral Drilling Machines are built to deliver high performance and precision, ensuring efficient and accurate drilling operations. They are often used in conjunction with other types of drilling equipment to provide a comprehensive drilling solution for various projects. Both Long and Short Spiral Drilling Machines play a crucial role in the Global Spiral Blade Drilling Machine Market, catering to the diverse needs of different industries. The choice between the two types of machines depends on the specific requirements of the project, including the depth of drilling needed, the type of soil or rock to be drilled, and the overall scope of the project. Advances in technology have led to the development of more sophisticated and efficient drilling machines, with features such as enhanced power systems, improved blade designs, and advanced control mechanisms. These innovations have significantly improved the performance and reliability of both Long and Short Spiral Drilling Machines, making them indispensable tools in the modern construction and mining industries. In summary, Long Spiral Drilling Machines are best suited for deep drilling applications, offering robust performance and reliability for complex projects, while Short Spiral Drilling Machines are ideal for shallower drilling tasks, providing precision and efficiency in more confined or accessible areas. Both types of machines are essential components of the Global Spiral Blade Drilling Machine Market, addressing the varied needs of industries that rely on efficient and effective drilling solutions. As technology continues to advance, the capabilities and applications of these machines are expected to expand, further enhancing their role in supporting infrastructure development, resource extraction, and other critical activities.

Mining, Oil and Gas, Railway and Highway, Others in the Global Spiral Blade Drilling Machine Market:

The Global Spiral Blade Drilling Machine Market finds extensive usage across various sectors, including mining, oil and gas, railway and highway construction, and other industries. In the mining sector, these machines are crucial for drilling operations that involve extracting minerals and other valuable resources from the earth. The efficiency and precision of spiral blade drilling machines make them ideal for creating boreholes and tunnels, which are essential for accessing and transporting mined materials. Their ability to handle different soil and rock types ensures that mining operations can proceed smoothly, even in challenging conditions. Additionally, the advanced features of these machines, such as automated controls and real-time monitoring, enhance safety and productivity in mining activities. In the oil and gas industry, spiral blade drilling machines are used for drilling wells to extract oil and natural gas from underground reservoirs. These machines are designed to handle the high pressures and temperatures associated with drilling in these environments, ensuring that the drilling process is both efficient and safe. The precision of spiral blade drilling machines is particularly important in this sector, as it helps to minimize the risk of blowouts and other drilling-related accidents. Furthermore, the ability of these machines to drill through various types of rock and soil makes them versatile tools for oil and gas exploration and production activities. Railway and highway construction projects also benefit significantly from the use of spiral blade drilling machines. In these sectors, the machines are used for creating foundations for bridges, tunnels, and other infrastructure components. The ability to drill deep and precise holes ensures that the foundations are stable and secure, which is critical for the safety and longevity of the infrastructure. Additionally, the efficiency of spiral blade drilling machines helps to reduce the time and cost associated with construction projects, making them valuable assets for contractors and project managers. The versatility of these machines also allows them to be used in various soil and rock conditions, ensuring that construction projects can proceed smoothly regardless of the terrain. Beyond mining, oil and gas, and construction, spiral blade drilling machines are also used in other industries, such as geothermal energy, water well drilling, and environmental engineering. In geothermal energy projects, these machines are used to drill deep wells to access geothermal reservoirs, which are then used to generate electricity or provide heating. The precision and efficiency of spiral blade drilling machines are crucial in these projects, as they help to ensure that the wells are properly constructed and can operate effectively. In water well drilling, these machines are used to create boreholes for accessing groundwater, which is then used for drinking water, irrigation, and other purposes. The ability of spiral blade drilling machines to handle different soil and rock types ensures that water wells can be drilled in various locations, providing access to clean water in areas where it is needed most. In environmental engineering, spiral blade drilling machines are used for soil sampling, groundwater monitoring, and other activities that help to assess and mitigate environmental impacts. The precision and reliability of these machines are essential for obtaining accurate data, which is critical for making informed decisions about environmental management and remediation. Overall, the Global Spiral Blade Drilling Machine Market plays a vital role in supporting a wide range of industries, providing the tools and technology needed to carry out essential drilling operations efficiently and effectively.

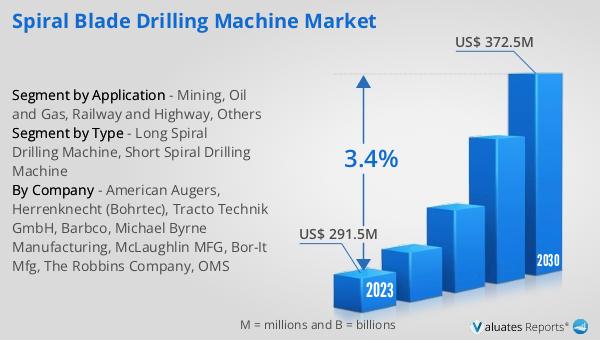

Global Spiral Blade Drilling Machine Market Outlook:

The global Spiral Blade Drilling Machine market was valued at US$ 291.5 million in 2023 and is anticipated to reach US$ 372.5 million by 2030, witnessing a CAGR of 3.4% during the forecast period 2024-2030. According to our Construction Machinery research center, sales of construction machinery in Europe increased by 24% in 2021, and in 2022, the construction machinery revenue in Europe was about US$ 22 billion, while the US market sold about US$ 36 billion in construction machinery in 2022.

| Report Metric | Details |

| Report Name | Spiral Blade Drilling Machine Market |

| Accounted market size in 2023 | US$ 291.5 million |

| Forecasted market size in 2030 | US$ 372.5 million |

| CAGR | 3.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | American Augers, Herrenknecht (Bohrtec), Tracto Technik GmbH, Barbco, Michael Byrne Manufacturing, McLaughlin MFG, Bor-It Mfg, The Robbins Company, OMS |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |