What is Global Non-Woven Needle Felts Market?

The Global Non-Woven Needle Felts Market is a specialized segment within the broader textile industry, focusing on the production and distribution of needle-punched non-woven fabrics. These fabrics are created by mechanically interlocking fibers through a process called needle punching, which involves repeatedly piercing a web of fibers with barbed needles. This method results in a dense, durable fabric that is highly versatile and used in various applications. Non-woven needle felts are known for their strength, flexibility, and resistance to wear and tear, making them ideal for industrial and commercial uses. The market for these materials is driven by their increasing demand in sectors such as automotive, construction, and filtration, where their unique properties offer significant advantages over traditional woven fabrics. Additionally, the market is influenced by technological advancements in manufacturing processes, which enhance the quality and performance of non-woven needle felts. As industries continue to seek efficient and cost-effective materials, the global non-woven needle felts market is expected to grow, driven by innovation and the expanding range of applications for these versatile fabrics.

Wool, Polypropylene, Polyester, Others in the Global Non-Woven Needle Felts Market:

In the Global Non-Woven Needle Felts Market, materials such as wool, polypropylene, polyester, and others play a crucial role in determining the characteristics and applications of the final product. Wool, a natural fiber, is prized for its excellent insulation properties, moisture-wicking ability, and biodegradability. It is often used in applications where thermal insulation and environmental sustainability are priorities. Wool needle felts are commonly found in the construction industry for soundproofing and insulation purposes, as well as in the automotive sector for interior components. Polypropylene, a synthetic polymer, is favored for its lightweight, chemical resistance, and affordability. It is widely used in industrial filtration systems, where its resistance to acids and bases makes it ideal for filtering aggressive substances. Polypropylene needle felts are also used in geotextiles, where they provide stability and reinforcement in civil engineering projects. Polyester, another synthetic fiber, is known for its strength, durability, and resistance to stretching and shrinking. Polyester needle felts are commonly used in applications requiring high tensile strength and resistance to environmental factors, such as automotive interiors, roofing materials, and protective clothing. Other materials used in the production of non-woven needle felts include acrylic, nylon, and aramid fibers, each offering unique properties that cater to specific industrial needs. Acrylic fibers, for instance, are valued for their resistance to UV degradation and are often used in outdoor applications. Nylon fibers provide excellent abrasion resistance and are used in applications where durability is paramount. Aramid fibers, known for their heat resistance and strength, are used in high-performance applications such as protective gear and industrial filtration. The choice of material in the production of non-woven needle felts is critical, as it directly impacts the performance, durability, and suitability of the fabric for specific applications. Manufacturers often blend different fibers to achieve a balance of properties, optimizing the fabric for its intended use. As the demand for non-woven needle felts continues to grow, the development of new materials and fiber blends will play a significant role in expanding the market's potential and meeting the evolving needs of various industries.

Industrial Filtration, Automotive, Building Materials, Others in the Global Non-Woven Needle Felts Market:

The Global Non-Woven Needle Felts Market finds extensive usage across several key areas, including industrial filtration, automotive, building materials, and others. In industrial filtration, non-woven needle felts are used to create filter bags, cartridges, and panels that effectively capture particles and contaminants from air and liquid streams. Their high porosity and durability make them ideal for use in industries such as chemical processing, food and beverage, and pharmaceuticals, where maintaining clean and contaminant-free environments is crucial. In the automotive sector, non-woven needle felts are used for sound insulation, vibration dampening, and thermal insulation in vehicle interiors. They are also used in the production of air and oil filters, contributing to improved vehicle performance and efficiency. The lightweight and flexible nature of these materials make them suitable for use in various automotive components, enhancing comfort and reducing noise levels. In the construction industry, non-woven needle felts are used as building materials for insulation, roofing, and soundproofing. Their ability to provide thermal insulation and reduce energy consumption makes them an attractive choice for sustainable building practices. Additionally, they are used in geotextiles for soil stabilization and erosion control, contributing to the longevity and stability of construction projects. Beyond these primary applications, non-woven needle felts are also used in a variety of other industries, including furniture manufacturing, packaging, and apparel. In furniture manufacturing, they are used as padding and cushioning materials, providing comfort and support. In packaging, they offer protective cushioning for fragile items, ensuring safe transportation and storage. In the apparel industry, non-woven needle felts are used in the production of hats, bags, and other accessories, where their lightweight and durable properties are highly valued. The versatility and adaptability of non-woven needle felts make them an essential material in numerous industries, driving their demand and expanding their market potential.

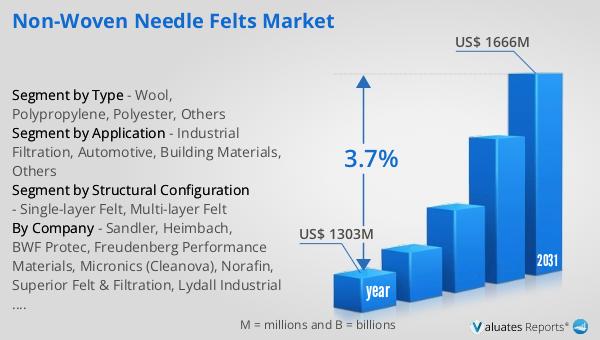

Global Non-Woven Needle Felts Market Outlook:

The global market for Non-Woven Needle Felts was valued at approximately USD 1,303 million in 2024. It is anticipated to grow steadily, reaching an estimated size of USD 1,666 million by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 3.7% over the forecast period. The market's expansion is driven by the increasing demand for durable and versatile materials across various industries, including automotive, construction, and industrial filtration. As these sectors continue to evolve and innovate, the need for high-performance materials like non-woven needle felts becomes more pronounced. The market's growth is also supported by advancements in manufacturing technologies, which enhance the quality and performance of these fabrics, making them more appealing to a broader range of applications. Additionally, the growing emphasis on sustainability and environmental responsibility is encouraging the adoption of non-woven needle felts, as they offer eco-friendly alternatives to traditional materials. As a result, the global non-woven needle felts market is poised for continued growth, driven by innovation, technological advancements, and the expanding range of applications for these versatile fabrics.

| Report Metric | Details |

| Report Name | Non-Woven Needle Felts Market |

| Accounted market size in year | US$ 1303 million |

| Forecasted market size in 2031 | US$ 1666 million |

| CAGR | 3.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Structural Configuration |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sandler, Heimbach, BWF Protec, Freudenberg Performance Materials, Micronics (Cleanova), Norafin, Superior Felt & Filtration, Lydall Industrial Filtration, Jindal Cotspin, Buffalo Felt, Bouckaert Industrial Textiles, Sutherland Felt, US Felt, Shri Radhika Nonwoven, Fybagrate, Monarch Textiles, Bonfilt, Delaware Valley, PARK Nonwoven, Zhejiang Heading Environment Technology, Taizhou Haotian Industrial Fabric, Huizhou Jinhaocheng Non-Woven Fabric, Hebei Huaren Felt, Changshu Zhongyi Nonwoven Manufacturing, HL Filter |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |