What is Global Forged Check Valves Market?

The Global Forged Check Valves Market is a significant segment within the broader industrial valves industry, characterized by its specialized function in controlling the flow of fluids. Forged check valves are designed to allow fluid to flow in one direction while preventing backflow, which is crucial in maintaining the efficiency and safety of various systems. These valves are manufactured through a forging process, which involves shaping metal using localized compressive forces, resulting in a product that is robust and durable. The global market for these valves is driven by their widespread application across numerous industries, including oil and gas, power generation, and water treatment, among others. The demand for forged check valves is influenced by factors such as industrial growth, technological advancements, and the need for efficient fluid control systems. As industries continue to expand and modernize, the requirement for reliable and high-performance valves is expected to grow, making the Global Forged Check Valves Market a vital component of industrial infrastructure. The market's growth is also supported by the increasing emphasis on energy efficiency and the need to reduce operational costs, which forged check valves help achieve by minimizing leakage and ensuring smooth operation.

Swing Check Valves, Lift Check Valves, Piston Check Valves, Ball Check Valves, Wafer Check Valves in the Global Forged Check Valves Market:

Swing Check Valves, Lift Check Valves, Piston Check Valves, Ball Check Valves, and Wafer Check Valves are all integral components of the Global Forged Check Valves Market, each serving distinct purposes and applications. Swing Check Valves are designed with a disc that swings on a hinge or shaft, allowing fluid to flow in one direction. When the flow stops, the disc swings back to its seat, preventing backflow. These valves are commonly used in pipelines where flow reversal could cause damage or disrupt operations. Lift Check Valves, on the other hand, have a disc that lifts off its seat to allow flow and returns to its position when the flow stops. They are suitable for high-pressure applications and are often used in steam, gas, and liquid systems. Piston Check Valves feature a piston that moves within a cylinder to control flow. They are known for their tight sealing capabilities and are used in applications where leakage prevention is critical. Ball Check Valves use a ball to block the reverse flow, and they are typically used in low-pressure applications where space is limited. Wafer Check Valves are compact and lightweight, designed to fit between flanges in a piping system. They are ideal for applications where space and weight are concerns, such as in marine and offshore environments. Each type of check valve offers unique advantages, making them suitable for specific applications within the Global Forged Check Valves Market. The choice of valve depends on factors such as the type of fluid, pressure, temperature, and the specific requirements of the system. As industries continue to evolve, the demand for these specialized valves is expected to grow, driven by the need for efficient and reliable fluid control solutions.

Oil & Gas, Power Generation, Petrochemical, Water Treatment, Marine, Pulp & Paper, Pharmaceutical, Industrial, Others in the Global Forged Check Valves Market:

The Global Forged Check Valves Market finds extensive usage across various industries, each with its unique requirements and challenges. In the oil and gas sector, forged check valves are crucial for ensuring the safe and efficient transport of hydrocarbons. They prevent backflow, which can lead to pipeline damage and environmental hazards. In power generation, these valves play a vital role in maintaining the integrity of steam and water systems, ensuring that power plants operate smoothly and efficiently. The petrochemical industry relies on forged check valves to handle aggressive chemicals and high-pressure environments, where reliability and durability are paramount. Water treatment facilities use these valves to control the flow of water and prevent contamination, ensuring the delivery of clean and safe water. In the marine industry, forged check valves are used in ballast systems and other critical applications where space and weight are limited. The pulp and paper industry utilizes these valves to manage the flow of pulp and chemicals, ensuring efficient production processes. In the pharmaceutical industry, forged check valves are essential for maintaining sterile conditions and preventing contamination in the production of medicines. Industrial applications of these valves are vast, ranging from manufacturing to food processing, where they help maintain process integrity and efficiency. Other sectors, such as HVAC and fire protection, also benefit from the reliable performance of forged check valves. The versatility and reliability of these valves make them indispensable across a wide range of industries, contributing to the growth and development of the Global Forged Check Valves Market.

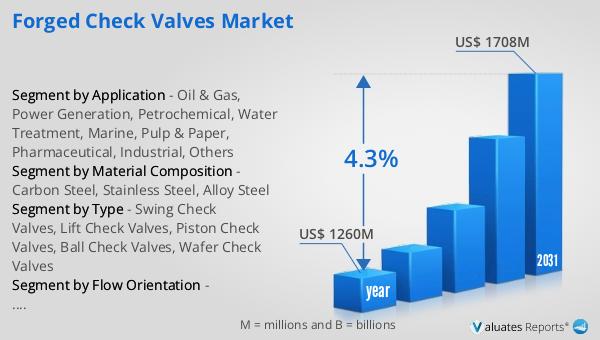

Global Forged Check Valves Market Outlook:

The global market for Forged Check Valves was valued at $1,260 million in 2024 and is anticipated to expand to a revised size of $1,708 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.3% during the forecast period. This growth trajectory underscores the increasing demand for efficient and reliable fluid control solutions across various industries. The market's expansion is driven by factors such as industrial growth, technological advancements, and the need for energy-efficient systems. As industries continue to modernize and expand, the requirement for high-performance valves that can withstand harsh conditions and prevent backflow becomes more critical. The emphasis on reducing operational costs and enhancing system efficiency further fuels the demand for forged check valves. Additionally, the growing focus on environmental sustainability and the need to minimize leakage and waste contribute to the market's growth. The Global Forged Check Valves Market is poised for significant development, supported by the increasing adoption of advanced technologies and the continuous evolution of industrial processes. As the market continues to grow, manufacturers are likely to invest in research and development to create innovative solutions that meet the evolving needs of various industries.

| Report Metric | Details |

| Report Name | Forged Check Valves Market |

| Accounted market size in year | US$ 1260 million |

| Forecasted market size in 2031 | US$ 1708 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Pressure Rating |

|

| Segment by Material Composition |

|

| Segment by Flow Orientation |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Bonney Forge, Powell Valves, Smith Valves, Velan Inc., Walworth, Topper Forged Valve, Chaoda Valves, Zigong Valve, Athena Engineering, DI Nicola Infinam, Syveco, ARAKO, Warren Valve, IMI Critical Engineering |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |