What is Global Pneumatic Airless Sprayer Market?

The Global Pneumatic Airless Sprayer Market refers to the worldwide industry focused on the production, distribution, and utilization of pneumatic airless sprayers. These devices are used to apply paint or other coatings without the need for compressed air, relying instead on high-pressure pumps to atomize the coating material. This market encompasses a variety of industries, including construction, automotive, furniture, and machinery, where efficient and uniform application of coatings is essential. The market is driven by the demand for high-quality finishes, increased efficiency, and reduced wastage of materials. Innovations in technology and the growing need for eco-friendly and cost-effective solutions are also significant factors contributing to the market's growth. The global reach of this market means that it is influenced by regional economic conditions, industrial growth, and advancements in manufacturing processes.

High Pressure, Low Pressure in the Global Pneumatic Airless Sprayer Market:

High-pressure and low-pressure pneumatic airless sprayers are two primary types of equipment used in the Global Pneumatic Airless Sprayer Market, each serving different purposes based on the requirements of the application. High-pressure pneumatic airless sprayers operate at pressures typically above 1,500 PSI (pounds per square inch), making them suitable for heavy-duty tasks where thick coatings or large surface areas need to be covered quickly and efficiently. These sprayers are commonly used in industrial settings, such as in the machinery and automotive industries, where robust and durable finishes are required. The high pressure ensures that the coating material is atomized into fine particles, providing a smooth and even application. On the other hand, low-pressure pneumatic airless sprayers operate at pressures below 1,500 PSI and are designed for more delicate tasks where precision and control are paramount. These sprayers are ideal for applications in the furniture industry and architectural projects where a finer finish is desired. The lower pressure reduces overspray and material wastage, making them more economical and environmentally friendly. Both types of sprayers have their advantages and are chosen based on the specific needs of the project. High-pressure sprayers are favored for their speed and efficiency in covering large areas, while low-pressure sprayers are preferred for their precision and ability to handle more intricate work. The choice between high-pressure and low-pressure sprayers also depends on the type of coating material being used. High-viscosity materials, such as heavy-duty industrial paints, are better suited for high-pressure sprayers, while low-viscosity materials, like stains and lacquers, are more effectively applied with low-pressure sprayers. Additionally, the surface to be coated plays a crucial role in determining the appropriate sprayer. Rough and uneven surfaces may require the force of a high-pressure sprayer to ensure complete coverage, whereas smooth and detailed surfaces benefit from the gentle application of a low-pressure sprayer. The versatility of pneumatic airless sprayers in handling different pressures and materials makes them indispensable tools in various industries. Their ability to provide consistent and high-quality finishes, coupled with the efficiency of application, drives their widespread adoption. As technology advances, the development of more sophisticated sprayers that can switch between high and low pressures seamlessly is expected to further enhance their utility and appeal in the market.

Achitechive, Power Industry, Machinery Industry, Automobile Industry, Furniture Industry in the Global Pneumatic Airless Sprayer Market:

The Global Pneumatic Airless Sprayer Market finds extensive usage across various industries, including architecture, power, machinery, automobile, and furniture. In the architectural sector, these sprayers are used for painting large surfaces such as walls, ceilings, and exteriors of buildings. The ability to apply paint quickly and evenly makes them ideal for both residential and commercial projects. They help in achieving a professional finish with minimal effort, reducing labor costs and time. In the power industry, pneumatic airless sprayers are employed for coating power plants, transformers, and other electrical equipment. The protective coatings applied using these sprayers help in preventing corrosion and extending the lifespan of the equipment. This is crucial for maintaining the efficiency and reliability of power generation and distribution systems. In the machinery industry, these sprayers are used for applying protective and decorative coatings to various types of machinery and equipment. The high-pressure sprayers are particularly useful for coating large and complex machinery parts, ensuring that every nook and cranny is covered. This not only enhances the appearance of the machinery but also protects it from wear and tear. The automobile industry also relies heavily on pneumatic airless sprayers for painting vehicles. These sprayers provide a smooth and even finish, which is essential for the aesthetic appeal of cars and other vehicles. They are used in both the manufacturing process and for aftermarket services such as repainting and touch-ups. The ability to apply paint quickly and efficiently helps in speeding up the production process and reducing costs. In the furniture industry, low-pressure pneumatic airless sprayers are commonly used for applying finishes to wooden furniture. These sprayers allow for precise control, ensuring that the finish is applied evenly without any drips or runs. This is important for achieving a high-quality finish that enhances the appearance and durability of the furniture. The versatility of pneumatic airless sprayers makes them valuable tools in these industries, helping to improve efficiency, reduce costs, and achieve high-quality finishes.

Global Pneumatic Airless Sprayer Market Outlook:

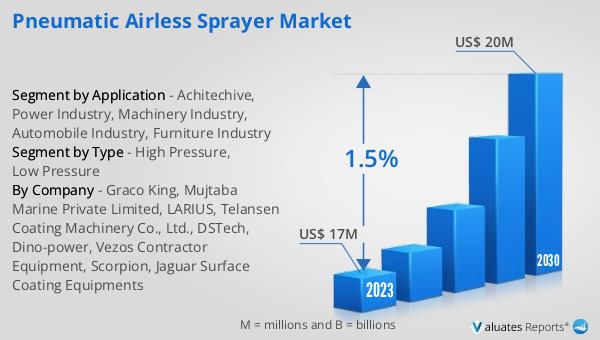

The global Pneumatic Airless Sprayer market was valued at US$ 17 million in 2023 and is anticipated to reach US$ 20 million by 2030, witnessing a CAGR of 1.5% during the forecast period 2024-2030. According to our Construction Machinery research center, sales of construction machinery in Europe increased by 24% in 2021, and in 2022, the construction machinery revenue in Europe was about US$ 22 billion, while the US market sold about $36 billion in construction machinery in 2022.

| Report Metric | Details |

| Report Name | Pneumatic Airless Sprayer Market |

| Accounted market size in 2023 | US$ 17 million |

| Forecasted market size in 2030 | US$ 20 million |

| CAGR | 1.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Graco King, Mujtaba Marine Private Limited, LARIUS, Telansen Coating Machinery Co., Ltd., DSTech, Dino-power, Vezos Contractor Equipment, Scorpion, Jaguar Surface Coating Equipments |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |