What is Global Octyl Tin Mercaptide Market?

The Global Octyl Tin Mercaptide Market is a specialized segment within the broader chemical industry, focusing on the production and distribution of octyl tin mercaptide compounds. These compounds are primarily used as stabilizers in the manufacturing of polyvinyl chloride (PVC) products. Octyl tin mercaptide acts as a heat stabilizer, which is crucial in preventing the degradation of PVC when exposed to high temperatures during processing. This market is driven by the increasing demand for PVC products across various industries, including construction, automotive, and packaging. The versatility of PVC, combined with the stabilizing properties of octyl tin mercaptide, makes this market an essential component of the global chemical industry. As industries continue to seek materials that offer durability and cost-effectiveness, the demand for octyl tin mercaptide is expected to grow, further solidifying its position in the market. The market's growth is also influenced by regulatory standards and environmental considerations, as manufacturers strive to produce more sustainable and eco-friendly products. Overall, the Global Octyl Tin Mercaptide Market plays a vital role in supporting the production of high-quality PVC products, meeting the needs of various industries worldwide.

Purity≥98.0%, Purity≥99.0% in the Global Octyl Tin Mercaptide Market:

In the Global Octyl Tin Mercaptide Market, purity levels are a critical factor that influences the quality and performance of the final product. Two common purity levels are Purity≥98.0% and Purity≥99.0%. These purity levels refer to the concentration of octyl tin mercaptide in the compound, with higher purity levels indicating fewer impurities and a more refined product. Purity≥98.0% is often considered the standard for many applications, providing a balance between performance and cost. This level of purity is suitable for most PVC applications, offering adequate stabilization properties to prevent degradation during processing. However, for applications that require higher performance and more stringent quality standards, Purity≥99.0% is preferred. This higher purity level ensures that the stabilizer performs optimally, providing enhanced heat resistance and longevity to the PVC products. The choice between these purity levels depends on the specific requirements of the application, as well as cost considerations. Manufacturers must carefully evaluate the needs of their products and the expectations of their customers to determine the appropriate purity level. Additionally, advancements in production technology and quality control processes have made it possible to achieve higher purity levels more consistently, further expanding the options available to manufacturers. As the demand for high-quality PVC products continues to rise, the importance of purity levels in the Global Octyl Tin Mercaptide Market cannot be overstated. Manufacturers must remain vigilant in maintaining the desired purity levels to ensure the performance and reliability of their products. This focus on purity is not only essential for meeting customer expectations but also for complying with regulatory standards and environmental guidelines. As the market evolves, the emphasis on purity levels is likely to increase, driving innovation and improvements in production processes. Ultimately, the choice of purity level in the Global Octyl Tin Mercaptide Market is a critical decision that impacts the quality, performance, and competitiveness of PVC products in the global market.

PVC Profiles, PVC Pipes, PVC Sheets, Others in the Global Octyl Tin Mercaptide Market:

The Global Octyl Tin Mercaptide Market plays a significant role in the production of various PVC products, including PVC profiles, PVC pipes, PVC sheets, and others. In the case of PVC profiles, octyl tin mercaptide is used as a stabilizer to enhance the durability and heat resistance of the profiles. These profiles are commonly used in construction for windows, doors, and other structural components. The stabilizing properties of octyl tin mercaptide ensure that the profiles maintain their shape and integrity even when exposed to varying temperatures and environmental conditions. Similarly, in the production of PVC pipes, octyl tin mercaptide is essential for preventing degradation during the extrusion process. PVC pipes are widely used in plumbing, irrigation, and drainage systems, where they are exposed to different pressures and temperatures. The use of octyl tin mercaptide ensures that the pipes remain strong and resistant to cracking or breaking over time. For PVC sheets, which are used in a variety of applications such as signage, cladding, and packaging, octyl tin mercaptide provides the necessary stabilization to maintain the sheets' flexibility and strength. This is particularly important in applications where the sheets are subjected to bending or impact. Beyond these specific applications, octyl tin mercaptide is also used in other PVC products, such as cables, films, and coatings. In each of these applications, the stabilizer plays a crucial role in enhancing the performance and longevity of the products. The versatility of octyl tin mercaptide makes it an indispensable component in the PVC industry, supporting the production of high-quality and reliable products. As industries continue to demand materials that offer superior performance and cost-effectiveness, the use of octyl tin mercaptide in PVC products is expected to grow. This growth is driven by the need for durable and sustainable materials that can withstand the challenges of modern applications. Overall, the Global Octyl Tin Mercaptide Market is integral to the production of a wide range of PVC products, meeting the diverse needs of industries worldwide.

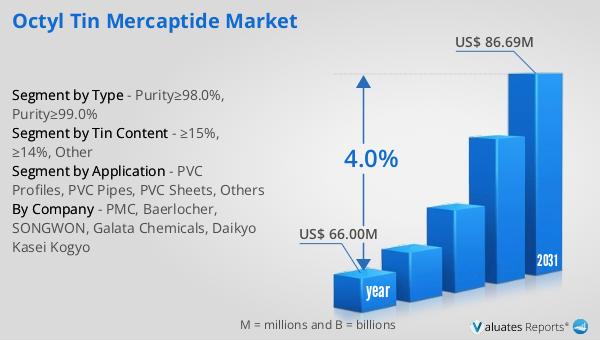

Global Octyl Tin Mercaptide Market Outlook:

In 2024, the global market for Octyl Tin Mercaptide was valued at approximately US$ 66.00 million. This market is anticipated to expand, reaching an estimated value of US$ 86.69 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.0% over the forecast period. The steady increase in market size reflects the rising demand for octyl tin mercaptide, driven by its critical role as a stabilizer in the production of PVC products. As industries continue to seek materials that offer enhanced durability and performance, the demand for high-quality stabilizers like octyl tin mercaptide is expected to grow. This growth is further supported by advancements in production technology and the increasing emphasis on sustainability and environmental compliance. The market's expansion is also influenced by the growing construction and automotive industries, which rely heavily on PVC products for various applications. As these industries continue to evolve and expand, the demand for octyl tin mercaptide is likely to increase, driving further growth in the market. Overall, the Global Octyl Tin Mercaptide Market is poised for steady growth, supported by the increasing demand for high-quality PVC products and the ongoing advancements in production technology.

| Report Metric | Details |

| Report Name | Octyl Tin Mercaptide Market |

| Accounted market size in year | US$ 66.00 million |

| Forecasted market size in 2031 | US$ 86.69 million |

| CAGR | 4.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Tin Content |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | PMC, Baerlocher, SONGWON, Galata Chemicals, Daikyo Kasei Kogyo |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |