What is Global Butyl Tin Mercaptide Market?

The Global Butyl Tin Mercaptide Market is a specialized segment within the broader chemical industry, focusing on the production and distribution of butyl tin mercaptide compounds. These compounds are primarily used as stabilizers in the manufacturing of polyvinyl chloride (PVC) products. Butyl tin mercaptides are organotin compounds that play a crucial role in enhancing the heat stability and processing performance of PVC, making them indispensable in various industrial applications. The market for these compounds is driven by the growing demand for PVC products across different sectors, including construction, automotive, and packaging. As industries continue to seek materials that offer durability and cost-effectiveness, the demand for butyl tin mercaptides is expected to rise. The market is characterized by a few key players who dominate the production and supply, ensuring consistent quality and availability of these stabilizers. Additionally, regulatory standards and environmental considerations are influencing the market dynamics, as manufacturers strive to develop formulations that meet stringent safety and environmental guidelines. Overall, the Global Butyl Tin Mercaptide Market is poised for growth, driven by technological advancements and the expanding applications of PVC products worldwide.

Purity≥98.0%, Purity≥99.0% in the Global Butyl Tin Mercaptide Market:

In the Global Butyl Tin Mercaptide Market, purity levels play a significant role in determining the quality and performance of the stabilizers used in PVC products. Two common purity levels are Purity≥98.0% and Purity≥99.0%, each offering distinct advantages and applications. Purity≥98.0% refers to butyl tin mercaptide compounds that contain at least 98% of the active ingredient, with the remaining 2% comprising impurities or other substances. This level of purity is generally sufficient for standard applications where high precision and performance are not critical. Products with Purity≥98.0% are often used in general-purpose PVC applications, where cost-effectiveness is a priority, and the performance requirements are moderate. On the other hand, Purity≥99.0% indicates a higher level of refinement, with at least 99% of the compound being the active ingredient. This higher purity level is crucial for applications that demand superior performance, such as in the production of high-quality PVC products that require enhanced heat stability and resistance to degradation. The higher purity ensures that the stabilizer performs optimally, providing better protection against thermal degradation and extending the lifespan of the PVC products. In industries where precision and reliability are paramount, such as in medical or food-grade applications, Purity≥99.0% is often the preferred choice. The choice between these purity levels depends on several factors, including the specific requirements of the application, cost considerations, and regulatory standards. Manufacturers must carefully evaluate these factors to select the appropriate purity level that meets their needs while ensuring compliance with industry regulations. As the demand for high-performance PVC products continues to grow, the importance of selecting the right purity level in butyl tin mercaptide stabilizers becomes increasingly critical. This decision impacts not only the quality and durability of the final products but also the overall efficiency and sustainability of the manufacturing process. Therefore, understanding the nuances of purity levels in the Global Butyl Tin Mercaptide Market is essential for manufacturers and end-users alike, as they navigate the complexities of the modern industrial landscape.

PVC Profiles, PVC Pipes, PVC Sheets, Others in the Global Butyl Tin Mercaptide Market:

The Global Butyl Tin Mercaptide Market finds extensive usage in various PVC applications, including PVC profiles, PVC pipes, PVC sheets, and other related products. In the realm of PVC profiles, butyl tin mercaptides serve as essential stabilizers that enhance the thermal stability and processing performance of the material. PVC profiles are widely used in the construction industry for windows, doors, and other structural components due to their durability and resistance to environmental factors. The inclusion of butyl tin mercaptides ensures that these profiles maintain their structural integrity and appearance over time, even when exposed to harsh weather conditions. Similarly, in the production of PVC pipes, butyl tin mercaptides play a crucial role in preventing thermal degradation during the extrusion process. PVC pipes are commonly used in plumbing, irrigation, and sewage systems, where they are subjected to varying temperatures and pressures. The stabilizing properties of butyl tin mercaptides help in maintaining the mechanical strength and longevity of the pipes, ensuring reliable performance in demanding applications. In the case of PVC sheets, which are used in a variety of applications ranging from signage to interior design, butyl tin mercaptides contribute to the material's flexibility and resistance to discoloration. The stabilizers help in preserving the aesthetic qualities of the sheets, making them suitable for both functional and decorative purposes. Beyond these specific applications, butyl tin mercaptides are also used in other PVC products, such as cables, films, and coatings, where their stabilizing properties are equally beneficial. The versatility of butyl tin mercaptides in enhancing the performance and durability of PVC products underscores their importance in the market. As industries continue to innovate and expand the use of PVC materials, the demand for effective stabilizers like butyl tin mercaptides is expected to grow, driving further advancements in the Global Butyl Tin Mercaptide Market.

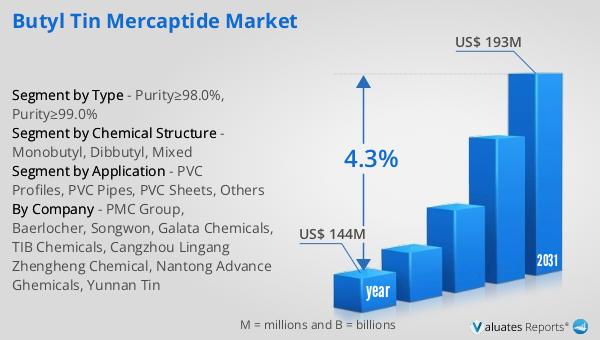

Global Butyl Tin Mercaptide Market Outlook:

The outlook for the Global Butyl Tin Mercaptide Market indicates a promising trajectory, with the market valued at US$ 144 million in 2024 and projected to reach a revised size of US$ 193 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.3% during the forecast period. The steady increase in market size reflects the rising demand for butyl tin mercaptides as essential stabilizers in the production of PVC products. As industries across the globe continue to seek materials that offer enhanced performance and cost-effectiveness, the role of butyl tin mercaptides becomes increasingly significant. The market's expansion is driven by the growing applications of PVC in various sectors, including construction, automotive, and packaging, where the need for durable and reliable materials is paramount. Additionally, advancements in manufacturing technologies and the development of new formulations are expected to further boost the market's growth. The focus on sustainability and environmental compliance also plays a crucial role in shaping the market dynamics, as manufacturers strive to meet regulatory standards while delivering high-quality products. Overall, the Global Butyl Tin Mercaptide Market is poised for continued growth, driven by the increasing demand for PVC products and the ongoing innovations in stabilizer technologies.

| Report Metric | Details |

| Report Name | Butyl Tin Mercaptide Market |

| Accounted market size in year | US$ 144 million |

| Forecasted market size in 2031 | US$ 193 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Chemical Structure |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | PMC Group, Baerlocher, Songwon, Galata Chemicals, TIB Chemicals, Cangzhou Lingang Zhengheng Chemical, Nantong Advance Ghemicals, Yunnan Tin |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |