What is Global Air-bearing Variable Frequency Centrifugal Chiller Market?

The Global Air-bearing Variable Frequency Centrifugal Chiller Market is a specialized segment within the broader HVAC (Heating, Ventilation, and Air Conditioning) industry. These chillers are advanced cooling systems that utilize air-bearing technology combined with variable frequency drives to enhance efficiency and performance. Air-bearing technology eliminates the need for traditional lubricants by using a cushion of air to support the rotating components, reducing friction and wear. This results in lower maintenance requirements and longer operational life. The variable frequency drive allows the chiller to adjust its speed based on the cooling demand, optimizing energy consumption and reducing operational costs. These chillers are particularly beneficial in applications where precision and reliability are crucial, such as in data centers, hospitals, and industrial processes. The market for these chillers is driven by the increasing demand for energy-efficient cooling solutions and the growing awareness of environmental sustainability. As industries and commercial sectors strive to reduce their carbon footprint, the adoption of air-bearing variable frequency centrifugal chillers is expected to rise, offering a promising outlook for this market segment.

Water-cooled, Air-cooled in the Global Air-bearing Variable Frequency Centrifugal Chiller Market:

In the realm of the Global Air-bearing Variable Frequency Centrifugal Chiller Market, two primary types of chillers are prevalent: water-cooled and air-cooled systems. Water-cooled chillers are typically more efficient than their air-cooled counterparts, as they use water to dissipate heat, which is a more effective medium for heat transfer. These systems are often used in larger installations where space is not a constraint, such as in industrial plants or large commercial buildings. They require a cooling tower and a constant supply of water, which can be a limitation in areas with water scarcity. However, their efficiency in energy consumption makes them a preferred choice in many applications. On the other hand, air-cooled chillers use ambient air to dissipate heat and are generally used in smaller installations or where water resources are limited. They are easier to install and maintain since they do not require a cooling tower or water supply. However, they tend to be less efficient than water-cooled systems, especially in hotter climates where the ambient air temperature is high. Despite this, air-cooled chillers are popular in regions where water conservation is a priority or where installation space is limited. Both types of chillers benefit from the integration of air-bearing and variable frequency technologies. The air-bearing technology reduces mechanical wear and tear, leading to lower maintenance costs and longer equipment life. The variable frequency drive allows the chiller to adjust its operational speed based on real-time cooling demands, optimizing energy usage and reducing electricity costs. This adaptability makes these chillers suitable for a wide range of applications, from commercial buildings to industrial processes. The choice between water-cooled and air-cooled systems often depends on specific project requirements, including factors such as installation space, water availability, and energy efficiency goals. As the demand for sustainable and energy-efficient cooling solutions continues to grow, both water-cooled and air-cooled air-bearing variable frequency centrifugal chillers are expected to see increased adoption across various sectors.

Commercial Buildings, Public Buildings, Industrial Process Cooling in the Global Air-bearing Variable Frequency Centrifugal Chiller Market:

The Global Air-bearing Variable Frequency Centrifugal Chiller Market finds extensive usage across several key areas, including commercial buildings, public buildings, and industrial process cooling. In commercial buildings, these chillers are integral to maintaining a comfortable indoor environment, ensuring optimal temperature and humidity levels for occupants. They are commonly used in office complexes, shopping malls, and hotels, where energy efficiency and reliability are paramount. The variable frequency drive technology allows these chillers to adjust their cooling output based on the building's real-time needs, reducing energy consumption and operational costs. In public buildings, such as schools, hospitals, and government facilities, air-bearing variable frequency centrifugal chillers play a crucial role in providing a stable and comfortable environment. These buildings often have fluctuating occupancy levels and varying cooling demands, making the adaptability of these chillers particularly beneficial. The reduced maintenance requirements and longer lifespan of air-bearing technology also contribute to lower operational costs, which is a significant consideration for publicly funded institutions. In industrial process cooling, these chillers are used to remove excess heat generated by manufacturing processes, ensuring the smooth operation of machinery and maintaining product quality. Industries such as pharmaceuticals, food and beverage, and electronics manufacturing rely on precise temperature control to meet stringent quality standards. The energy efficiency and reliability of air-bearing variable frequency centrifugal chillers make them an ideal choice for these applications, where downtime and inefficiency can lead to significant financial losses. Overall, the versatility and efficiency of these chillers make them a valuable asset across various sectors, contributing to energy savings and environmental sustainability.

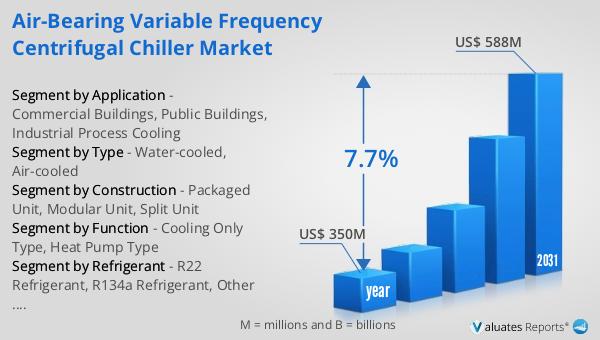

Global Air-bearing Variable Frequency Centrifugal Chiller Market Outlook:

The global market for Air-bearing Variable Frequency Centrifugal Chillers was valued at $350 million in 2024 and is anticipated to expand to a revised size of $588 million by 2031, reflecting a compound annual growth rate (CAGR) of 7.7% over the forecast period. This growth trajectory underscores the increasing demand for energy-efficient and environmentally friendly cooling solutions across various industries. The adoption of air-bearing technology, which reduces mechanical friction and extends the lifespan of chillers, is a key factor driving this market expansion. Additionally, the integration of variable frequency drives allows these chillers to optimize their performance based on real-time cooling demands, further enhancing their appeal to businesses seeking to reduce energy consumption and operational costs. As industries and commercial sectors continue to prioritize sustainability and cost-efficiency, the market for these advanced chillers is expected to grow steadily. The projected market growth also reflects the broader trend towards adopting innovative technologies that align with global environmental goals and energy efficiency standards. As a result, the Global Air-bearing Variable Frequency Centrifugal Chiller Market is poised for significant growth, offering promising opportunities for manufacturers and stakeholders in the HVAC industry.

| Report Metric | Details |

| Report Name | Air-bearing Variable Frequency Centrifugal Chiller Market |

| Accounted market size in year | US$ 350 million |

| Forecasted market size in 2031 | US$ 588 million |

| CAGR | 7.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Refrigerant |

|

| Segment by Function |

|

| Segment by Construction |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Trane, Carrier, LG Electronics, Climaveneta, Midea, Zhejiang SINO KING Refrigeration, Jiangsu Sujing, Nanjing Jiuding Environmental Technology, SANHER, Shanghai Nuobing Refrigeration Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |