What is Global Cryogenic Swivel Joints Market?

The Global Cryogenic Swivel Joints Market is a specialized segment within the broader industrial equipment market, focusing on the production and distribution of swivel joints designed to operate under extremely low temperatures. These joints are crucial components in systems that handle cryogenic fluids, which are substances that require storage and transportation at temperatures below -150 degrees Celsius. The primary function of cryogenic swivel joints is to facilitate the smooth and flexible movement of pipes and hoses, preventing leaks and ensuring the safe transfer of cryogenic liquids and gases. Industries such as oil and gas, chemical processing, and liquefied natural gas (LNG) heavily rely on these joints to maintain operational efficiency and safety. The market is driven by the increasing demand for LNG and other cryogenic applications, as well as advancements in technology that enhance the durability and performance of these joints. As global energy needs continue to grow, the cryogenic swivel joints market is expected to expand, offering innovative solutions to meet the challenges of handling cryogenic materials. The market's growth is also supported by stringent safety regulations and the need for reliable equipment in critical applications.

Single-Passage Swivel Joints, Dual-Passage Swivel Joints, Multi-Passage Swivel Joints in the Global Cryogenic Swivel Joints Market:

Single-Passage Swivel Joints, Dual-Passage Swivel Joints, and Multi-Passage Swivel Joints are integral components of the Global Cryogenic Swivel Joints Market, each serving distinct purposes based on their design and application. Single-Passage Swivel Joints are designed to allow the flow of a single fluid or gas through a rotating connection, making them ideal for applications where a straightforward, uninterrupted flow is required. These joints are commonly used in systems where space is limited, and the movement of a single line is necessary, such as in certain industrial gas applications or specific sections of LNG transfer systems. Their simplicity and efficiency make them a cost-effective solution for many cryogenic applications. Dual-Passage Swivel Joints, on the other hand, are engineered to accommodate two separate flow paths within a single joint. This design is particularly useful in applications where simultaneous transfer of two different fluids or gases is needed, such as in certain chemical processing operations or in systems that require both cooling and heating lines to operate concurrently. The dual-passage design allows for greater flexibility and efficiency, reducing the need for multiple connections and minimizing potential leak points. Multi-Passage Swivel Joints take this concept further by incorporating multiple flow paths within a single joint, allowing for the transfer of several different fluids or gases simultaneously. These joints are essential in complex systems where multiple lines need to be managed in a compact space, such as in advanced LNG processing facilities or in aerospace applications where space and weight are at a premium. The ability to handle multiple passages within a single joint reduces the overall complexity of the system, enhances reliability, and improves safety by minimizing the number of potential failure points. Each type of swivel joint is designed to meet specific operational requirements, and the choice between single, dual, or multi-passage designs depends on the specific needs of the application. Factors such as the type of fluid or gas being transferred, the required flow rate, and the environmental conditions all play a role in determining the most suitable swivel joint for a given application. As the demand for cryogenic applications continues to grow, manufacturers are continually innovating to improve the performance and reliability of these joints, ensuring they can meet the evolving needs of industries that rely on cryogenic technology.

Industrial Gas, Power Generation, Healthcare Facilities, Marine Operations, Aerospace & Defense, Others in the Global Cryogenic Swivel Joints Market:

The Global Cryogenic Swivel Joints Market finds extensive usage across various sectors, each with unique requirements and challenges. In the Industrial Gas sector, cryogenic swivel joints are essential for the safe and efficient transfer of gases like nitrogen, oxygen, and argon, which are often stored and transported in liquid form at extremely low temperatures. These joints ensure that the gases can be moved without leaks or interruptions, maintaining the integrity of the supply chain and supporting industries such as manufacturing, food processing, and electronics. In Power Generation, cryogenic swivel joints play a crucial role in systems that utilize liquefied natural gas (LNG) as a fuel source. The ability to safely and efficiently transfer LNG is vital for power plants that rely on this cleaner-burning fuel to reduce emissions and meet regulatory standards. Cryogenic swivel joints help facilitate the movement of LNG from storage tanks to the power generation units, ensuring a steady and reliable supply of fuel. Healthcare Facilities also benefit from the use of cryogenic swivel joints, particularly in the storage and handling of medical gases and cryogenic liquids used in various medical procedures and research applications. These joints ensure that critical supplies are delivered safely and efficiently, supporting patient care and medical research. In Marine Operations, cryogenic swivel joints are used in the transfer of LNG and other cryogenic fuels for ships and offshore platforms. The ability to handle these fuels safely is essential for the maritime industry as it seeks to reduce emissions and comply with international environmental regulations. Cryogenic swivel joints provide the flexibility and reliability needed to support these operations, ensuring that vessels can refuel quickly and safely. Aerospace & Defense applications also rely on cryogenic swivel joints for the handling of cryogenic fuels and other materials used in propulsion systems and other advanced technologies. The ability to manage these materials safely and efficiently is critical for the success of aerospace missions and defense operations. Finally, in other sectors such as research and development, cryogenic swivel joints are used in laboratories and testing facilities where cryogenic materials are studied and utilized. The versatility and reliability of these joints make them an indispensable component in a wide range of applications, supporting innovation and progress across multiple industries.

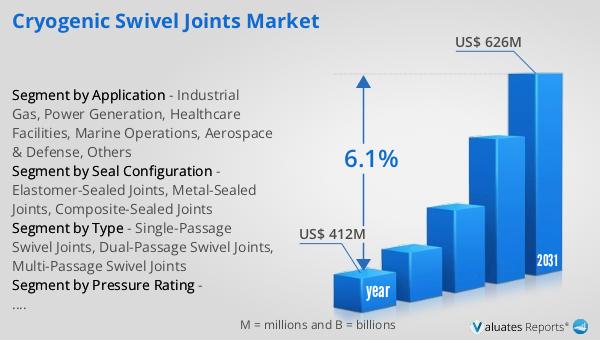

Global Cryogenic Swivel Joints Market Outlook:

In 2024, the global market for Cryogenic Swivel Joints was valued at approximately $412 million. This market is anticipated to grow significantly, reaching an estimated value of $626 million by 2031. This growth represents a compound annual growth rate (CAGR) of 6.1% over the forecast period. The increasing demand for cryogenic applications, driven by the expanding use of liquefied natural gas (LNG) and other cryogenic materials, is a key factor contributing to this market expansion. As industries continue to seek efficient and reliable solutions for handling cryogenic fluids, the demand for advanced swivel joint technology is expected to rise. The market's growth is also supported by technological advancements that enhance the performance and durability of cryogenic swivel joints, as well as by stringent safety regulations that require the use of high-quality components in critical applications. As a result, manufacturers are investing in research and development to create innovative products that meet the evolving needs of their customers. The projected growth of the Cryogenic Swivel Joints Market reflects the increasing importance of cryogenic technology in various industries and the ongoing efforts to improve the safety and efficiency of cryogenic systems.

| Report Metric | Details |

| Report Name | Cryogenic Swivel Joints Market |

| Accounted market size in year | US$ 412 million |

| Forecasted market size in 2031 | US$ 626 million |

| CAGR | 6.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Pressure Rating |

|

| Segment by Seal Configuration |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | EMCO Wheaton, KANON Loading Equipment, Technip Energies, Woodfield Systems, JLA Loading Technology, TB Global Technologies, Tokyo Boeki Holdings, Changlong Petrochemical Equipment, Excel Loading Systems, Marlia Engineering, Wagenborg Loading Technology, Huade Loading Arm, Autoware Group, Demaco Holland |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |