What is Global Phenolic Resin for Casting Coated Sand Market?

The Global Phenolic Resin for Casting Coated Sand Market is a specialized segment within the broader chemical industry, focusing on the production and application of phenolic resins specifically designed for use in casting coated sand. Phenolic resins are synthetic polymers obtained through the reaction of phenol with formaldehyde. These resins are known for their excellent thermal stability, mechanical strength, and resistance to chemical degradation, making them ideal for use in high-temperature environments such as metal casting. In the casting process, coated sand is used to create molds and cores, which are essential for shaping molten metal into desired forms. The phenolic resin acts as a binder, holding the sand grains together and ensuring the mold retains its shape under the intense heat of molten metal. This market is driven by the demand for high-quality castings in various industries, including automotive, aerospace, and construction. As these industries continue to grow, the need for efficient and reliable casting materials like phenolic resin-coated sand is expected to rise, making this market a critical component of the global manufacturing landscape.

Solid, Liquid in the Global Phenolic Resin for Casting Coated Sand Market:

In the Global Phenolic Resin for Casting Coated Sand Market, phenolic resins are available in two primary forms: solid and liquid. Each form has distinct characteristics and applications, catering to different needs within the casting industry. Solid phenolic resins are typically supplied as powders or granules. These are often preferred for their ease of handling and storage, as they do not require special containers to prevent spillage or evaporation. Solid resins are mixed with sand to create a uniform coating, which is then used to form molds and cores. The solid form is particularly advantageous in applications where precise control over the resin-to-sand ratio is crucial, as it allows for consistent mixing and distribution. Additionally, solid phenolic resins are known for their long shelf life, making them a cost-effective choice for manufacturers who require bulk storage. On the other hand, liquid phenolic resins offer different benefits. They are typically used in applications where rapid curing and high reactivity are essential. Liquid resins can penetrate sand grains more effectively, ensuring a strong bond and enhancing the overall strength of the mold. This form is particularly useful in high-speed production environments where quick turnaround times are necessary. Liquid phenolic resins also allow for greater flexibility in formulation, enabling manufacturers to tailor the resin properties to specific casting requirements. However, they require careful handling and storage to prevent premature curing or degradation. Both solid and liquid phenolic resins play a vital role in the casting industry, offering unique advantages that cater to different production needs. The choice between solid and liquid forms often depends on factors such as the specific casting process, the type of metal being cast, and the desired properties of the final product. As the demand for high-quality castings continues to grow, the versatility and adaptability of phenolic resins will remain a key factor in their widespread adoption across various industries.

Cast Iron/Steel, Non-Ferrous Alloys, Other in the Global Phenolic Resin for Casting Coated Sand Market:

The Global Phenolic Resin for Casting Coated Sand Market finds extensive usage across various sectors, particularly in the casting of different metals such as cast iron, steel, non-ferrous alloys, and others. In the casting of cast iron and steel, phenolic resin-coated sand is crucial due to its ability to withstand high temperatures and maintain mold integrity. Cast iron and steel are commonly used in the automotive and construction industries for components like engine blocks, pipes, and structural elements. The phenolic resin ensures that the molds and cores used in casting these metals can endure the intense heat and pressure without breaking down, resulting in high-quality, defect-free castings. For non-ferrous alloys, which include metals like aluminum, copper, and zinc, phenolic resin-coated sand offers similar benefits. Non-ferrous metals are often used in applications where weight reduction and corrosion resistance are critical, such as in aerospace and electronics. The use of phenolic resin in casting these alloys ensures precise mold formation and excellent surface finish, which are essential for meeting the stringent quality standards of these industries. Additionally, phenolic resin-coated sand is used in other casting applications, including the production of artistic sculptures, decorative items, and specialized industrial components. In these cases, the resin's ability to produce intricate details and smooth surfaces is highly valued. The versatility of phenolic resin in accommodating different casting requirements makes it an indispensable material in the foundry industry. As industries continue to innovate and demand more complex and high-performance castings, the role of phenolic resin-coated sand in ensuring quality and efficiency will only become more significant.

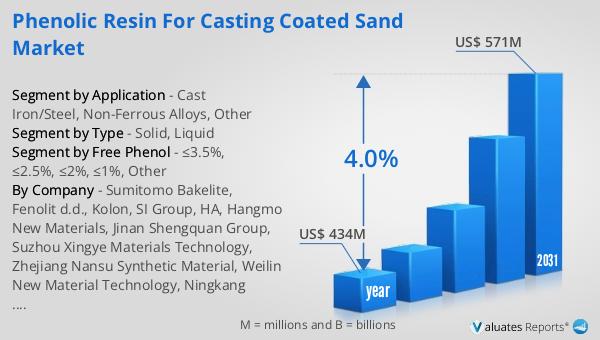

Global Phenolic Resin for Casting Coated Sand Market Outlook:

The global market for Phenolic Resin for Casting Coated Sand was valued at $434 million in 2024 and is anticipated to grow to a revised size of $571 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.0% over the forecast period. This growth trajectory underscores the increasing demand for phenolic resin-coated sand in various industrial applications. The market's expansion is driven by the rising need for high-quality castings in sectors such as automotive, aerospace, and construction, where precision and durability are paramount. As industries continue to evolve and require more sophisticated casting solutions, the demand for phenolic resin-coated sand is expected to rise. The market's growth is also supported by advancements in resin technology, which enhance the performance and efficiency of casting processes. Manufacturers are continually innovating to develop resins that offer improved thermal stability, mechanical strength, and environmental sustainability. These innovations are crucial in meeting the evolving needs of industries that rely on casting for critical components. The projected growth of the Phenolic Resin for Casting Coated Sand Market highlights its importance as a key material in the global manufacturing landscape, providing essential solutions for producing high-quality castings across various sectors.

| Report Metric | Details |

| Report Name | Phenolic Resin for Casting Coated Sand Market |

| Accounted market size in year | US$ 434 million |

| Forecasted market size in 2031 | US$ 571 million |

| CAGR | 4.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Free Phenol |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sumitomo Bakelite, Fenolit d.d., Kolon, SI Group, HA, Hangmo New Materials, Jinan Shengquan Group, Suzhou Xingye Materials Technology, Zhejiang Nansu Synthetic Material, Weilin New Material Technology, Ningkang Chemical, Sichuan EM Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |