What is Global Industrial Colloidal Silica Market?

The Global Industrial Colloidal Silica Market is a significant segment within the broader chemical industry, characterized by its diverse applications and growing demand across various sectors. Colloidal silica is essentially a stable dispersion of fine silica particles in a liquid, typically water. These particles are incredibly small, usually in the nanometer range, which gives colloidal silica its unique properties. The market for industrial colloidal silica is driven by its versatility and the increasing demand for high-performance materials in industries such as electronics, textiles, and chemicals. The global market is witnessing steady growth due to advancements in manufacturing processes and the rising need for specialized materials that offer enhanced durability, stability, and performance. The market's expansion is also fueled by the growing trend towards sustainable and environmentally friendly products, as colloidal silica is often used as a safer alternative to more hazardous chemicals. As industries continue to innovate and seek out materials that can improve product performance while reducing environmental impact, the demand for colloidal silica is expected to rise, making it a crucial component in the future of industrial manufacturing.

Alkaline Colloidal Silica, Acidic Colloidal Silica, Modified Colloidal Silica, Ordinary Colloidal Silica in the Global Industrial Colloidal Silica Market:

Alkaline colloidal silica, acidic colloidal silica, modified colloidal silica, and ordinary colloidal silica each play distinct roles within the Global Industrial Colloidal Silica Market, catering to various industrial needs based on their unique properties. Alkaline colloidal silica is characterized by its high pH level, which makes it particularly useful in applications where stability in alkaline conditions is required. This type of colloidal silica is often used in the production of catalysts, where it acts as a binder and enhances the mechanical strength and thermal stability of the catalyst. Its ability to withstand high pH environments makes it ideal for use in industries such as petrochemicals and wastewater treatment, where alkaline conditions are prevalent. On the other hand, acidic colloidal silica has a low pH level, making it suitable for applications that require stability in acidic environments. This type of colloidal silica is commonly used in the paper and textile industries, where it serves as a retention aid and improves the quality and durability of the final product. Acidic colloidal silica is also used in the production of coatings and adhesives, where it enhances the adhesion and durability of the product. Modified colloidal silica refers to colloidal silica that has been chemically altered to enhance its properties for specific applications. This can include modifications to improve its thermal stability, mechanical strength, or compatibility with other materials. Modified colloidal silica is often used in high-performance applications such as electronics and advanced ceramics, where its enhanced properties can significantly improve the performance and longevity of the final product. Ordinary colloidal silica, on the other hand, is the most basic form of colloidal silica and is used in a wide range of applications due to its versatility and cost-effectiveness. It is commonly used as a binder in the production of refractory materials, where it helps to improve the strength and durability of the final product. Ordinary colloidal silica is also used in the production of paints and coatings, where it enhances the adhesion and durability of the product. Overall, each type of colloidal silica offers unique benefits and is used in a variety of applications across different industries, making them essential components of the Global Industrial Colloidal Silica Market.

Chemical Industry, Material Industry, Textile/Paper Industry, Electronics Industry in the Global Industrial Colloidal Silica Market:

The Global Industrial Colloidal Silica Market finds extensive usage across several industries, each leveraging its unique properties to enhance product performance and quality. In the chemical industry, colloidal silica is primarily used as a catalyst support and binder. Its ability to enhance the mechanical strength and thermal stability of catalysts makes it an invaluable component in chemical reactions, particularly in the production of petrochemicals and other complex chemical processes. The material industry benefits from colloidal silica's binding properties, which are crucial in the production of refractory materials. These materials require high durability and resistance to extreme temperatures, and colloidal silica helps achieve these characteristics by acting as a robust binder. In the textile and paper industry, colloidal silica is used as a retention aid, improving the quality and durability of the final product. It enhances the paper's printability and strength, making it a preferred choice for high-quality paper production. In textiles, colloidal silica is used to improve the fabric's texture and durability, ensuring that the final product meets the desired quality standards. The electronics industry utilizes colloidal silica in the production of semiconductors and other electronic components. Its ability to enhance thermal stability and mechanical strength makes it an ideal material for use in high-performance electronic devices. Colloidal silica is also used in the production of polishing slurries, which are essential in the manufacturing of electronic components, ensuring a smooth and defect-free surface. Overall, the versatility and unique properties of colloidal silica make it an essential component across various industries, driving its demand in the Global Industrial Colloidal Silica Market.

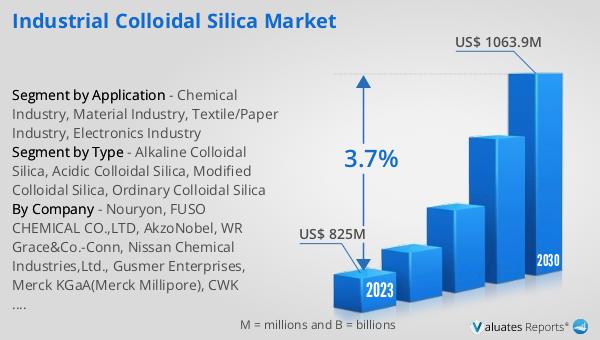

Global Industrial Colloidal Silica Market Outlook:

The outlook for the Global Industrial Colloidal Silica Market indicates a promising growth trajectory. In 2024, the market was valued at approximately $884 million, reflecting its significant role in various industrial applications. Looking ahead, the market is expected to expand, reaching an estimated size of $1,136 million by 2031. This growth is projected to occur at a compound annual growth rate (CAGR) of 3.7% over the forecast period. This steady increase in market size underscores the rising demand for colloidal silica across different sectors, driven by its unique properties and versatility. Industries such as electronics, textiles, and chemicals are increasingly adopting colloidal silica to enhance product performance and quality, contributing to the market's expansion. The growing emphasis on sustainable and environmentally friendly materials also plays a crucial role in driving demand, as colloidal silica offers a safer alternative to more hazardous chemicals. As industries continue to innovate and seek out materials that can improve product performance while reducing environmental impact, the Global Industrial Colloidal Silica Market is poised for continued growth, making it a vital component in the future of industrial manufacturing.

| Report Metric | Details |

| Report Name | Industrial Colloidal Silica Market |

| Accounted market size in year | US$ 884 million |

| Forecasted market size in 2031 | US$ 1136 million |

| CAGR | 3.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nouryon, FUSO CHEMICAL CO.,LTD, AkzoNobel, WR Grace&Co.-Conn, Nissan Chemical Industries,Ltd., Gusmer Enterprises, Merck KGaA(Merck Millipore), CWK Chemiewerk Bad Köstritz GmbH, Remet, ADEKA CORPORATION, NYACOL Nano Technologies,Inc., Evonik Industries, Elkhorn Plant, Teknor Apex |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |