What is Global Automatic Flatbed Die-Cutter Market?

The Global Automatic Flatbed Die-Cutter Market is a specialized segment within the broader machinery and equipment industry, focusing on machines designed to cut, shape, and process various materials with precision and efficiency. These machines are integral in industries that require high-volume and high-precision cutting, such as packaging, automotive, electronics, and textiles. The automatic flatbed die-cutter is a sophisticated piece of equipment that uses a flat surface to hold the material in place while a die, or cutting tool, moves over it to create the desired shape. This technology is favored for its ability to handle a wide range of materials, including paper, cardboard, plastics, and even some metals, making it versatile for different industrial applications. The market for these machines is driven by the increasing demand for customized and intricate designs in packaging and other sectors, as well as the need for efficient and cost-effective production processes. As industries continue to evolve and demand more complex and precise products, the role of automatic flatbed die-cutters becomes increasingly significant, supporting innovation and productivity across various sectors.

Blade Cutting, Laser Cutting in the Global Automatic Flatbed Die-Cutter Market:

In the realm of the Global Automatic Flatbed Die-Cutter Market, two prominent cutting technologies are blade cutting and laser cutting, each offering unique advantages and applications. Blade cutting is a traditional method that involves using a sharp blade to physically cut through materials. This technique is highly effective for materials like paper, cardboard, and thin plastics. Blade cutting is known for its precision and ability to produce clean, smooth edges, making it ideal for applications where the quality of the cut is paramount. The technology is also relatively cost-effective, as it does not require the high energy input associated with laser cutting. However, blade cutting may not be suitable for very thick or hard materials, as the physical force required can lead to wear and tear on the blades, necessitating frequent maintenance and replacement. On the other hand, laser cutting represents a more advanced and versatile technology within the Global Automatic Flatbed Die-Cutter Market. This method uses a focused laser beam to cut through materials, offering unparalleled precision and the ability to handle a wide range of materials, including metals, plastics, and composites. Laser cutting is particularly advantageous for intricate designs and complex shapes, as the laser can be precisely controlled to follow detailed patterns. Additionally, laser cutting produces minimal waste and can achieve high cutting speeds, enhancing overall production efficiency. The non-contact nature of laser cutting also means there is less wear and tear on the equipment, reducing maintenance costs over time. However, the initial investment for laser cutting equipment can be higher compared to blade cutting, and the technology requires skilled operators to manage and maintain the systems effectively. Both blade cutting and laser cutting have their place in the Global Automatic Flatbed Die-Cutter Market, with the choice between the two often depending on the specific requirements of the application. For industries that prioritize cost-effectiveness and simplicity, blade cutting remains a popular choice. In contrast, sectors that demand high precision and the ability to work with a diverse range of materials may opt for laser cutting. As technology continues to advance, we may see further innovations in both blade and laser cutting, potentially leading to even more efficient and versatile die-cutting solutions. The ongoing development in these technologies reflects the dynamic nature of the market, as manufacturers strive to meet the evolving needs of their customers while maintaining competitive advantages in terms of quality, speed, and cost.

Medical, Flexible Circuits, Digital Printing, Electric Vehicle Batteries, Others in the Global Automatic Flatbed Die-Cutter Market:

The Global Automatic Flatbed Die-Cutter Market finds extensive usage across various sectors, each benefiting from the precision and efficiency these machines offer. In the medical field, automatic flatbed die-cutters are crucial for producing medical devices and components that require high precision and consistency. These machines are used to cut materials for items such as surgical masks, medical tapes, and diagnostic equipment, where accuracy is critical to ensure the safety and effectiveness of the products. The ability to produce intricate shapes and designs with minimal waste makes these die-cutters invaluable in the medical industry, where material costs and regulatory compliance are significant considerations. In the realm of flexible circuits, automatic flatbed die-cutters play a vital role in the production of flexible printed circuit boards (PCBs) used in a wide range of electronic devices. These machines enable manufacturers to cut complex circuit patterns with high precision, ensuring the reliability and performance of the final product. The demand for flexible circuits is growing, driven by the increasing miniaturization of electronic devices and the need for lightweight, flexible components. Automatic flatbed die-cutters support this demand by providing efficient and accurate cutting solutions that meet the stringent quality standards of the electronics industry. Digital printing is another area where the Global Automatic Flatbed Die-Cutter Market is making a significant impact. As the demand for customized and short-run printing jobs increases, the need for efficient cutting solutions becomes more pronounced. Automatic flatbed die-cutters are used to cut printed materials into various shapes and sizes, enabling the production of customized packaging, labels, and promotional materials. The precision and speed of these machines allow for quick turnaround times, meeting the fast-paced demands of the digital printing industry. In the electric vehicle (EV) battery sector, automatic flatbed die-cutters are used to cut materials for battery components, such as separators and electrodes. The precision and consistency offered by these machines are essential for ensuring the performance and safety of EV batteries. As the demand for electric vehicles continues to rise, the need for efficient and reliable battery production processes becomes increasingly important. Automatic flatbed die-cutters support this demand by providing high-quality cutting solutions that contribute to the overall efficiency and effectiveness of battery manufacturing. Beyond these specific areas, the Global Automatic Flatbed Die-Cutter Market also serves a variety of other industries, including packaging, textiles, and automotive. In packaging, these machines are used to create custom packaging solutions that meet the unique needs of different products and brands. In textiles, automatic flatbed die-cutters enable the production of intricate fabric patterns and designs, supporting the fashion and home decor industries. In the automotive sector, these machines are used to cut materials for interior components, gaskets, and other parts that require precision and durability. Overall, the versatility and efficiency of automatic flatbed die-cutters make them indispensable tools across a wide range of industries. As technology continues to advance, these machines are likely to become even more integral to production processes, supporting innovation and growth in various sectors. The ability to produce high-quality, precise cuts with minimal waste and maximum efficiency ensures that the Global Automatic Flatbed Die-Cutter Market will continue to play a crucial role in modern manufacturing.

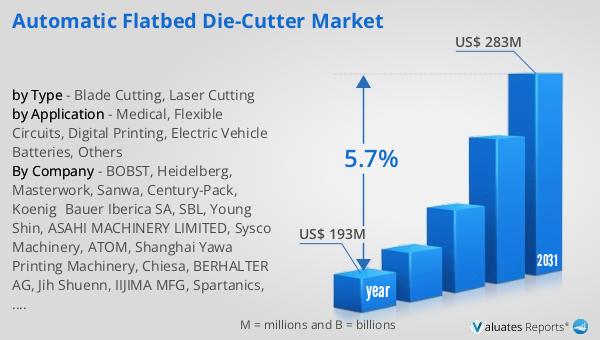

Global Automatic Flatbed Die-Cutter Market Outlook:

The outlook for the Global Automatic Flatbed Die-Cutter Market indicates a promising growth trajectory over the coming years. In 2024, the market was valued at approximately $193 million, reflecting the significant demand for these machines across various industries. By 2031, the market is expected to expand to a revised size of $283 million, driven by a compound annual growth rate (CAGR) of 5.7% during the forecast period. This growth is indicative of the increasing reliance on automatic flatbed die-cutters for precision cutting and shaping tasks in sectors such as packaging, electronics, automotive, and textiles. The projected growth of the market can be attributed to several factors, including the rising demand for customized and intricate designs in packaging and other industries. As consumer preferences continue to evolve, manufacturers are seeking efficient and cost-effective solutions to meet these demands, driving the adoption of automatic flatbed die-cutters. Additionally, advancements in technology are enhancing the capabilities of these machines, making them more versatile and efficient, further fueling market growth. The market's expansion is also supported by the growing emphasis on sustainability and waste reduction in manufacturing processes. Automatic flatbed die-cutters are known for their ability to produce precise cuts with minimal material waste, aligning with the increasing focus on environmentally friendly production practices. As industries continue to prioritize sustainability, the demand for efficient cutting solutions like automatic flatbed die-cutters is expected to rise. Overall, the Global Automatic Flatbed Die-Cutter Market is poised for significant growth in the coming years, driven by technological advancements, evolving consumer preferences, and the increasing emphasis on sustainability. As manufacturers continue to seek innovative solutions to enhance their production processes, the role of automatic flatbed die-cutters in supporting efficiency and precision will become increasingly important.

| Report Metric | Details |

| Report Name | Automatic Flatbed Die-Cutter Market |

| Accounted market size in year | US$ 193 million |

| Forecasted market size in 2031 | US$ 283 million |

| CAGR | 5.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | BOBST, Heidelberg, Masterwork, Sanwa, Century-Pack, Koenig&Bauer Iberica SA, SBL, Young Shin, ASAHI MACHINERY LIMITED, Sysco Machinery, ATOM, Shanghai Yawa Printing Machinery, Chiesa, BERHALTER AG, Jih Shuenn, IIJIMA MFG, Spartanics, Baysek Machines |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |