What is Electrodeposited Copper Foil for Printed Circuit Boards - Global Market?

Electrodeposited copper foil is a crucial component in the manufacturing of printed circuit boards (PCBs), which are the backbone of modern electronic devices. This type of copper foil is produced through an electrochemical process where copper ions are deposited onto a rotating drum, creating a thin, uniform layer of copper. This process allows for precise control over the thickness and quality of the copper foil, making it ideal for use in PCBs. The global market for electrodeposited copper foil is driven by the increasing demand for electronic devices, including smartphones, tablets, and computers, as well as the growing trend towards miniaturization and high-performance electronics. As technology advances, the need for more efficient and reliable PCBs continues to rise, further fueling the demand for high-quality electrodeposited copper foil. This market is characterized by a diverse range of applications, from consumer electronics to automotive and industrial sectors, each requiring specific properties and thicknesses of copper foil to meet their unique needs. The versatility and essential role of electrodeposited copper foil in the electronics industry underscore its importance in the global market.

Below 20 μm, 20-50 μm, Above 50 μm in the Electrodeposited Copper Foil for Printed Circuit Boards - Global Market:

Electrodeposited copper foil is available in various thicknesses, each serving different applications and requirements in the PCB industry. Foils below 20 μm are typically used in applications where space is at a premium, such as in smartphones and other compact electronic devices. These ultra-thin foils allow for the creation of smaller, lighter, and more efficient PCBs, which are essential in the design of modern electronics. The demand for these thin foils is driven by the ongoing trend towards miniaturization in the electronics industry, as manufacturers strive to pack more functionality into smaller devices. Foils in the 20-50 μm range are commonly used in a wide variety of applications, including consumer electronics, automotive, and industrial sectors. This thickness range offers a balance between performance and cost, making it a popular choice for many manufacturers. These foils provide the necessary conductivity and mechanical strength required for reliable PCB performance, while also being cost-effective for large-scale production. The versatility of this thickness range allows it to be used in a broad spectrum of applications, from simple consumer electronics to more complex industrial systems. Foils above 50 μm are typically used in applications that require higher current-carrying capacity and mechanical strength, such as in power electronics and heavy-duty industrial equipment. These thicker foils are capable of handling higher power levels and are often used in applications where durability and reliability are critical. The demand for these foils is driven by the increasing need for high-performance electronics in various industries, including automotive, aerospace, and renewable energy. As the demand for more powerful and efficient electronic systems continues to grow, the market for thicker electrodeposited copper foils is expected to expand. Each thickness category of electrodeposited copper foil plays a vital role in the PCB industry, catering to the diverse needs of different applications and sectors. The ability to produce copper foils in a range of thicknesses allows manufacturers to tailor their products to meet the specific requirements of their customers, ensuring optimal performance and reliability in a wide variety of electronic devices.

Single Sided Board, Double Sided Board, Multi Layered Board in the Electrodeposited Copper Foil for Printed Circuit Boards - Global Market:

Electrodeposited copper foil is used in various types of printed circuit boards, each serving different purposes and applications. In single-sided boards, the copper foil is applied to one side of the substrate, providing a conductive layer for the circuit. These boards are typically used in simple electronic devices where space and cost are primary considerations. The use of electrodeposited copper foil in single-sided boards allows for the creation of reliable and cost-effective circuits, making them a popular choice for consumer electronics and other low-complexity applications. In double-sided boards, copper foil is applied to both sides of the substrate, allowing for more complex circuit designs and increased functionality. This type of board is commonly used in applications where space is limited, but more complex circuitry is required, such as in automotive and industrial electronics. The use of electrodeposited copper foil in double-sided boards provides the necessary conductivity and mechanical strength to support more intricate circuit designs, enabling manufacturers to create more advanced and reliable electronic devices. Multi-layered boards are the most complex type of PCBs, consisting of multiple layers of copper foil separated by insulating material. These boards are used in high-performance applications where space is at a premium, and complex circuitry is required, such as in smartphones, computers, and other advanced electronic devices. The use of electrodeposited copper foil in multi-layered boards allows for the creation of highly efficient and reliable circuits, capable of handling the demands of modern electronics. The ability to produce copper foils in various thicknesses and qualities ensures that manufacturers can meet the specific requirements of each type of board, providing optimal performance and reliability in a wide range of applications. The versatility and essential role of electrodeposited copper foil in the PCB industry underscore its importance in the global market, as it continues to drive innovation and advancement in the electronics sector.

Electrodeposited Copper Foil for Printed Circuit Boards - Global Market Outlook:

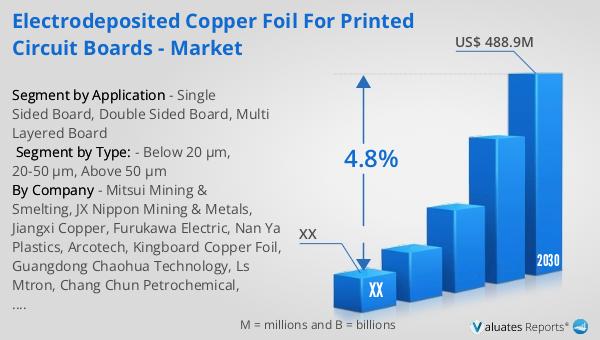

The global market for electrodeposited copper foil used in printed circuit boards was valued at approximately $334 million in 2023. This market is projected to grow significantly, reaching an estimated value of $488.9 million by 2030. This growth represents a compound annual growth rate (CAGR) of 4.8% during the forecast period from 2024 to 2030. The increasing demand for electronic devices, coupled with advancements in technology and the trend towards miniaturization, is driving the growth of this market. As more industries adopt electronic solutions, the need for reliable and efficient PCBs continues to rise, further fueling the demand for high-quality electrodeposited copper foil. The market's expansion is also supported by the growing automotive and industrial sectors, which require advanced electronic systems to enhance performance and efficiency. The versatility of electrodeposited copper foil, with its ability to cater to a wide range of applications and industries, makes it a critical component in the electronics market. As the market continues to evolve, manufacturers are focusing on developing innovative solutions to meet the changing needs of their customers, ensuring the continued growth and success of the electrodeposited copper foil market.

| Report Metric | Details |

| Report Name | Electrodeposited Copper Foil for Printed Circuit Boards - Market |

| Forecasted market size in 2030 | US$ 488.9 million |

| CAGR | 4.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Mitsui Mining & Smelting, JX Nippon Mining & Metals, Jiangxi Copper, Furukawa Electric, Nan Ya Plastics, Arcotech, Kingboard Copper Foil, Guangdong Chaohua Technology, Ls Mtron, Chang Chun Petrochemical, Minerex, Circuit Foil Luxembourg, Suzhou Fukuda Metal, LingBao Wason Copper Foil, Targray Technology International, Shandong Jinbao Electronics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |