What is Global GRP Cable Tray Systems Market?

The Global GRP Cable Tray Systems Market refers to the worldwide industry focused on the production and distribution of Glass Reinforced Plastic (GRP) cable tray systems. These systems are essential components in various industries for supporting insulated electric cables used for power distribution, control, and communication. GRP cable trays are favored for their durability, corrosion resistance, and lightweight properties, making them suitable for harsh environments. They are often used in industries such as IT and telecom, manufacturing, energy and utilities, oil and gas, and mining. The market is driven by the increasing demand for efficient cable management solutions that can withstand extreme conditions while ensuring safety and reliability. As industries continue to expand and modernize, the need for robust infrastructure solutions like GRP cable trays is expected to grow, contributing to the market's overall expansion. The market's growth is also supported by technological advancements and the development of new materials that enhance the performance and lifespan of these systems. Overall, the Global GRP Cable Tray Systems Market plays a crucial role in supporting the infrastructure needs of various sectors, ensuring the safe and efficient distribution of electrical power and communication signals.

GRP Ladder Type, GRP Perforated Type, Other Types in the Global GRP Cable Tray Systems Market:

GRP cable tray systems come in various types, each designed to meet specific needs and applications. The GRP Ladder Type is one of the most common forms, characterized by its ladder-like structure. This design allows for excellent ventilation and heat dissipation, making it ideal for environments where cables generate significant heat. The open design also facilitates easy installation and maintenance, as cables can be easily accessed and adjusted. This type is particularly popular in industries where large volumes of cables need to be managed efficiently, such as in data centers and industrial plants. The GRP Perforated Type, on the other hand, features a series of holes or slots along its surface. This design provides additional support for cables and is often used in applications where cable stability is a priority. The perforations also allow for some degree of ventilation, although not as much as the ladder type. This type is commonly used in commercial buildings and smaller industrial settings where cable loads are moderate. Other types of GRP cable trays include the GRP Solid Bottom Type and the GRP Trough Type. The Solid Bottom Type offers complete protection for cables, shielding them from dust, debris, and other environmental factors. This makes it suitable for outdoor applications or environments where cables need to be protected from external elements. The Trough Type, similar to the solid bottom, provides a high level of protection but with a slightly open top, allowing for some ventilation. This type is often used in industries where cables need to be protected from physical damage while still allowing for some airflow. Each type of GRP cable tray offers unique benefits and is chosen based on the specific requirements of the application. The versatility and adaptability of GRP cable tray systems make them a preferred choice for many industries looking to optimize their cable management solutions.

IT and Telecom, Manufacturing, Energy & Utility, Oil and Gas, Mining, Other in the Global GRP Cable Tray Systems Market:

The usage of Global GRP Cable Tray Systems Market spans across various industries, each benefiting from the unique properties of GRP materials. In the IT and Telecom sector, GRP cable trays are essential for managing the vast network of cables required for data transmission and communication. The lightweight and non-conductive nature of GRP makes it ideal for environments where electromagnetic interference needs to be minimized. Additionally, the durability and corrosion resistance of GRP ensure that the infrastructure remains reliable over time, even in challenging conditions. In the manufacturing industry, GRP cable trays are used to support the complex network of power and control cables that drive machinery and equipment. The ability to withstand high temperatures and resist chemical exposure makes GRP an excellent choice for manufacturing environments where harsh conditions are common. Energy and utility companies also rely heavily on GRP cable trays to manage the extensive cabling required for power distribution and control. The non-corrosive properties of GRP are particularly beneficial in outdoor installations where exposure to the elements is a concern. In the oil and gas industry, GRP cable trays are used to support the intricate network of cables required for exploration, extraction, and processing operations. The flame-retardant properties of GRP provide an added layer of safety in environments where fire hazards are a concern. Similarly, in the mining industry, GRP cable trays are used to manage the complex cabling systems required for underground and surface operations. The lightweight nature of GRP makes it easier to transport and install in remote locations, while its durability ensures long-term performance. Other industries, such as transportation and construction, also benefit from the use of GRP cable trays for their infrastructure needs. The versatility and adaptability of GRP cable tray systems make them a valuable asset in a wide range of applications, providing reliable and efficient cable management solutions across various sectors.

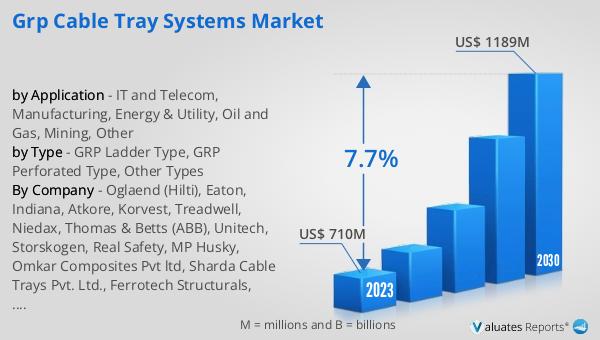

Global GRP Cable Tray Systems Market Outlook:

The global market for GRP Cable Tray Systems was valued at $762 million in 2024 and is anticipated to grow significantly, reaching an estimated $1,272 million by 2031. This growth represents a compound annual growth rate (CAGR) of 7.7% over the forecast period. This upward trend is indicative of the increasing demand for durable and efficient cable management solutions across various industries. The market's expansion is driven by the need for infrastructure that can withstand harsh environmental conditions while ensuring safety and reliability. As industries continue to modernize and expand, the demand for GRP cable tray systems is expected to rise, contributing to the market's overall growth. The projected increase in market size reflects the growing recognition of the benefits offered by GRP materials, including their lightweight, non-conductive, and corrosion-resistant properties. These attributes make GRP cable trays an attractive option for industries looking to optimize their cable management solutions. The market's growth is also supported by technological advancements and the development of new materials that enhance the performance and lifespan of GRP cable tray systems. Overall, the global GRP Cable Tray Systems Market is poised for significant growth, driven by the increasing demand for reliable and efficient infrastructure solutions across various sectors.

| Report Metric | Details |

| Report Name | GRP Cable Tray Systems Market |

| Accounted market size in year | US$ 762 million |

| Forecasted market size in 2031 | US$ 1272 million |

| CAGR | 7.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Oglaend (Hilti), Eaton, Indiana, Atkore, Korvest, Treadwell, Niedax, Thomas & Betts (ABB), Unitech, Storskogen, Real Safety, MP Husky, Omkar Composites Pvt ltd, Sharda Cable Trays Pvt. Ltd., Ferrotech Structurals, Fiber Tech Composite Private Limited, Fibex, EPP Composites, ERCON Composites, Hebei Longxin, Jiansu Huapeng, Hebei Chuangye, Zhenjiang Shenlong, King Sitong, Legrand |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |