What is Global ePTFE Tubing Market?

The Global ePTFE Tubing Market is a specialized segment within the broader tubing industry, focusing on the production and distribution of tubing made from expanded polytetrafluoroethylene (ePTFE). This material is renowned for its unique properties, including high chemical resistance, excellent thermal stability, and exceptional flexibility. ePTFE tubing is widely used across various industries due to these characteristics, making it a versatile choice for applications that require durability and reliability under extreme conditions. The market for ePTFE tubing is driven by its demand in sectors such as medical, industrial, and electronics, where precision and performance are critical. The tubing is manufactured through a specialized process that involves expanding and orienting PTFE, resulting in a product that is both soft and flexible, yet robust enough to withstand challenging environments. As industries continue to evolve and require more advanced materials, the demand for ePTFE tubing is expected to grow, reflecting its importance in modern manufacturing and technology applications. The market's growth is also supported by ongoing innovations and improvements in manufacturing techniques, which enhance the quality and performance of ePTFE tubing, making it an indispensable component in various high-tech applications.

≤0.5mm, >0.5mm in the Global ePTFE Tubing Market:

In the Global ePTFE Tubing Market, the size of the tubing plays a crucial role in determining its application and performance. Tubing with a diameter of ≤0.5mm is typically used in applications that require precision and minimal space, such as in medical devices and microelectronics. This size of tubing is ideal for situations where space is limited, and the tubing needs to navigate through tight spaces without compromising on performance. The small diameter allows for flexibility and ease of installation, making it a preferred choice in intricate systems. On the other hand, tubing with a diameter of >0.5mm is used in applications that require higher flow rates and greater structural integrity. This size is more suitable for industrial applications where the tubing needs to withstand higher pressures and more demanding conditions. The larger diameter provides the necessary strength and durability, ensuring that the tubing can handle the rigors of industrial use. Both sizes of ePTFE tubing offer the same benefits of chemical resistance and thermal stability, but their applications differ based on the specific requirements of the industry. The choice between ≤0.5mm and >0.5mm tubing depends on factors such as the nature of the fluid being transported, the operating environment, and the specific needs of the application. In the medical field, for example, ≤0.5mm tubing is often used in catheters and other devices that require precision and minimal invasiveness. The small size allows for easy insertion and maneuverability within the human body, making it an essential component in modern medical technology. In contrast, >0.5mm tubing is used in applications such as fluid transfer systems and industrial machinery, where the focus is on durability and performance under high-pressure conditions. The larger diameter provides the necessary strength to withstand the demands of these applications, ensuring reliable and efficient operation. Overall, the Global ePTFE Tubing Market offers a range of options to meet the diverse needs of various industries, with tubing sizes tailored to specific applications and performance requirements.

Industry, Medical, Other in the Global ePTFE Tubing Market:

The Global ePTFE Tubing Market finds extensive usage across various sectors, including industry, medical, and other specialized areas. In the industrial sector, ePTFE tubing is valued for its ability to withstand harsh environments and its resistance to chemicals and high temperatures. This makes it an ideal choice for applications such as chemical processing, where the tubing must transport corrosive substances without degrading. Its flexibility and durability also make it suitable for use in machinery and equipment that require reliable performance under demanding conditions. In the medical field, ePTFE tubing is used in a wide range of applications, from catheters and vascular grafts to surgical instruments and drug delivery systems. Its biocompatibility and flexibility make it an ideal material for medical devices that need to interact with the human body. The tubing's ability to be manufactured in small diameters allows for precision and minimal invasiveness, which is crucial in medical procedures. Additionally, ePTFE tubing is used in other specialized areas such as aerospace and electronics, where its unique properties are leveraged to meet the specific demands of these industries. In aerospace, for example, the tubing's lightweight and durable nature make it suitable for use in fuel lines and hydraulic systems, where performance and reliability are critical. In electronics, ePTFE tubing is used to protect sensitive components from environmental factors such as moisture and dust, ensuring the longevity and performance of electronic devices. Overall, the versatility and performance of ePTFE tubing make it a valuable component in a wide range of applications, driving its demand across various sectors.

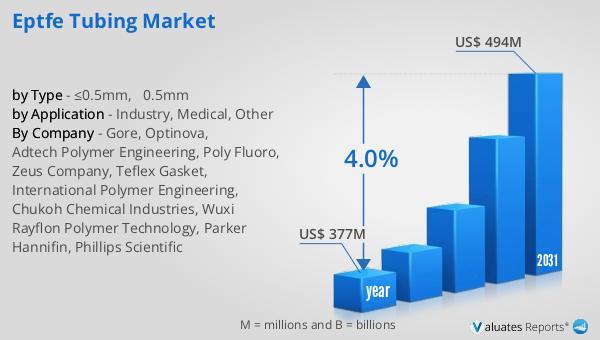

Global ePTFE Tubing Market Outlook:

The global market for ePTFE tubing was valued at approximately $377 million in 2024, with projections indicating it could reach around $494 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.0% over the forecast period. The unique properties of ePTFE tubing, such as its flexibility and softness, are achieved through a specialized extrusion process that expands and orients the PTFE material. This process enhances the tubing's performance, making it suitable for a wide range of applications across different industries. The market's growth is driven by the increasing demand for high-performance materials that can withstand extreme conditions and provide reliable performance. As industries continue to evolve and require more advanced solutions, the demand for ePTFE tubing is expected to rise, reflecting its importance in modern manufacturing and technology applications. The market's expansion is also supported by ongoing innovations and improvements in manufacturing techniques, which enhance the quality and performance of ePTFE tubing, making it an indispensable component in various high-tech applications. Overall, the global ePTFE tubing market is poised for steady growth, driven by its versatility and the increasing demand for advanced materials in various industries.

| Report Metric | Details |

| Report Name | ePTFE Tubing Market |

| Accounted market size in year | US$ 377 million |

| Forecasted market size in 2031 | US$ 494 million |

| CAGR | 4.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Gore, Optinova, Adtech Polymer Engineering, Poly Fluoro, Zeus Company, Teflex Gasket, International Polymer Engineering, Chukoh Chemical Industries, Wuxi Rayflon Polymer Technology, Parker Hannifin, Phillips Scientific |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |