What is Global ePTFE Joint Sealant Market?

The Global ePTFE Joint Sealant Market is a specialized segment within the broader industrial and medical sealant markets. ePTFE, or expanded polytetrafluoroethylene, is a versatile material known for its exceptional chemical resistance, flexibility, and durability. These properties make ePTFE joint sealants highly sought after in various applications where reliable sealing is crucial. The market for ePTFE joint sealants is driven by the increasing demand for high-performance sealing solutions in industries such as chemical processing, oil and gas, and pharmaceuticals. Additionally, the medical sector utilizes ePTFE for its biocompatibility and non-reactive nature, making it ideal for use in medical devices and implants. The market is characterized by continuous innovation and development of new products to meet the evolving needs of end-users. As industries continue to seek more efficient and reliable sealing solutions, the demand for ePTFE joint sealants is expected to grow, driven by their unique properties and adaptability to various applications.

StanDard Density, High Density, Full Density in the Global ePTFE Joint Sealant Market:

In the Global ePTFE Joint Sealant Market, the terms Standard Density, High Density, and Full Density refer to different types of ePTFE materials used in joint sealants, each with distinct characteristics and applications. Standard Density ePTFE is the most commonly used type, offering a balance between flexibility and strength. It is suitable for general-purpose sealing applications where moderate pressure and temperature conditions are present. This type of ePTFE is often used in industries such as food processing, where it provides a reliable seal without compromising the integrity of the materials being processed. High Density ePTFE, on the other hand, is designed for more demanding applications where higher pressure and temperature resistance are required. This type of ePTFE is less flexible than Standard Density but offers superior strength and durability, making it ideal for use in chemical processing and oil and gas industries. High Density ePTFE can withstand harsh environments and aggressive chemicals, providing a long-lasting seal that minimizes the risk of leaks and failures. Full Density ePTFE is the most robust type, offering the highest level of strength and resistance to extreme conditions. It is used in applications where maximum reliability is essential, such as in aerospace and defense industries. Full Density ePTFE can withstand extreme temperatures, pressures, and chemical exposures, ensuring a secure seal in the most challenging environments. The choice between Standard Density, High Density, and Full Density ePTFE depends on the specific requirements of the application, including the operating conditions and the level of performance needed. Manufacturers of ePTFE joint sealants continue to innovate and develop new formulations to meet the diverse needs of their customers, ensuring that there is a suitable option for every application. As industries continue to evolve and demand more advanced sealing solutions, the Global ePTFE Joint Sealant Market is expected to see continued growth and development.

Industry, Medical, Other in the Global ePTFE Joint Sealant Market:

The usage of Global ePTFE Joint Sealant Market products spans across various sectors, including industry, medical, and other specialized areas. In the industrial sector, ePTFE joint sealants are widely used due to their excellent chemical resistance and ability to withstand high temperatures and pressures. Industries such as chemical processing, oil and gas, and food and beverage rely on ePTFE sealants to ensure leak-proof operations and maintain the integrity of their systems. The flexibility and durability of ePTFE make it an ideal choice for sealing applications in pipelines, reactors, and other critical equipment. In the medical field, ePTFE is valued for its biocompatibility and non-reactive nature, making it suitable for use in medical devices and implants. ePTFE joint sealants are used in surgical procedures to create airtight seals, preventing contamination and ensuring patient safety. Additionally, ePTFE is used in the production of medical implants, such as vascular grafts and stents, where its flexibility and strength are crucial for long-term performance. Beyond industry and medical applications, ePTFE joint sealants find use in other specialized areas, such as electronics and aerospace. In electronics, ePTFE is used to seal components and protect them from moisture and dust, ensuring reliable performance. In the aerospace sector, ePTFE's ability to withstand extreme temperatures and pressures makes it an essential material for sealing applications in aircraft and spacecraft. The versatility and reliability of ePTFE joint sealants make them a valuable asset in a wide range of applications, driving their demand across various sectors. As industries continue to seek more efficient and reliable sealing solutions, the Global ePTFE Joint Sealant Market is poised for continued growth and innovation.

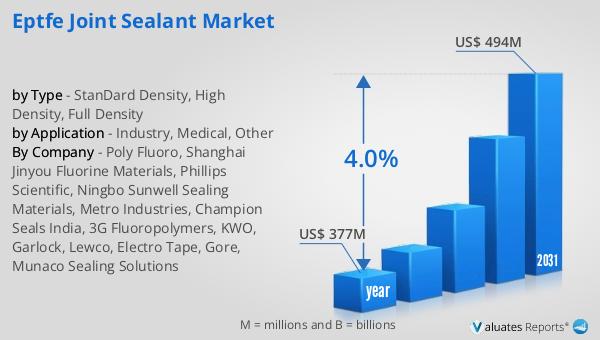

Global ePTFE Joint Sealant Market Outlook:

The global market for ePTFE Joint Sealant was valued at approximately $377 million in 2024, and it is anticipated to expand to a revised size of around $494 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.0% over the forecast period. The steady increase in market size reflects the growing demand for high-performance sealing solutions across various industries. As industries continue to evolve and face new challenges, the need for reliable and efficient sealing solutions becomes increasingly important. ePTFE joint sealants, with their unique properties and adaptability, are well-positioned to meet these demands. The market's growth is driven by the increasing adoption of ePTFE joint sealants in industries such as chemical processing, oil and gas, and pharmaceuticals, where their chemical resistance and durability are highly valued. Additionally, the medical sector's reliance on ePTFE for its biocompatibility and non-reactive nature further contributes to the market's expansion. As the global economy continues to recover and industries invest in new technologies and infrastructure, the demand for ePTFE joint sealants is expected to rise, supporting the market's growth over the forecast period.

| Report Metric | Details |

| Report Name | ePTFE Joint Sealant Market |

| Accounted market size in year | US$ 377 million |

| Forecasted market size in 2031 | US$ 494 million |

| CAGR | 4.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Poly Fluoro, Shanghai Jinyou Fluorine Materials, Phillips Scientific, Ningbo Sunwell Sealing Materials, Metro Industries, Champion Seals India, 3G Fluoropolymers, KWO, Garlock, Lewco, Electro Tape, Gore, Munaco Sealing Solutions |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |