What is Dog Dental Care Chews - Global Market?

Dog dental care chews are specialized products designed to promote oral health in dogs by reducing plaque and tartar buildup, freshening breath, and supporting overall dental hygiene. These chews are formulated with ingredients that help clean a dog's teeth as they chew, mimicking the natural process of gnawing on bones or other hard objects. The global market for dog dental care chews has been expanding due to increasing awareness among pet owners about the importance of oral health for their furry companions. As more people consider pets as part of their family, they are willing to invest in products that ensure their pets' well-being. This market is characterized by a variety of products that cater to different dog sizes, breeds, and specific dental needs. Manufacturers are continuously innovating to offer chews that are not only effective but also appealing in taste and texture to encourage regular use by dogs. The rise in pet ownership, coupled with a growing focus on preventive healthcare, has significantly contributed to the demand for dog dental care chews globally. Additionally, the convenience of these products makes them a popular choice among pet owners who seek easy-to-use solutions for maintaining their dogs' dental health.

Gluten-Containing, Gluten-Free in the Dog Dental Care Chews - Global Market:

The global market for dog dental care chews is witnessing a unique trend with the introduction of gluten-containing and gluten-free options. Gluten, a protein found in wheat and other grains, is sometimes included in dog chews to enhance texture and palatability. However, with the rising awareness of gluten sensitivities and allergies in both humans and pets, there has been a significant shift towards gluten-free products. This shift is driven by pet owners who are increasingly cautious about the ingredients in their pets' diets, mirroring trends in human food consumption. Gluten-free dog dental care chews are formulated to cater to dogs with specific dietary needs or sensitivities, ensuring that they can enjoy the benefits of dental chews without adverse reactions. These products often use alternative ingredients such as rice, potato, or tapioca starch to achieve the desired texture and effectiveness. The demand for gluten-free options is particularly strong in regions where gluten-free diets are popular among humans, as pet owners tend to extend their dietary preferences to their pets. On the other hand, gluten-containing chews continue to hold a significant share of the market, especially in areas where gluten sensitivities are less prevalent. These products are often favored for their cost-effectiveness and the ability to deliver a satisfying chewing experience for dogs. Manufacturers are tasked with balancing the need for diverse product offerings to cater to both segments of the market. The competition between gluten-containing and gluten-free dog dental care chews is driving innovation, with companies investing in research and development to create products that meet the evolving demands of pet owners. This includes improving the nutritional profile of chews, enhancing their dental benefits, and ensuring they are safe and enjoyable for dogs to consume. As the market continues to grow, it is expected that both gluten-containing and gluten-free options will coexist, providing pet owners with a wide range of choices to suit their dogs' individual needs. The emphasis on transparency and quality in ingredient sourcing is also becoming increasingly important, as consumers seek assurance that the products they purchase are safe and beneficial for their pets. This trend is likely to influence the marketing strategies of companies, as they highlight the health benefits and ingredient integrity of their products to attract discerning pet owners. Overall, the gluten-containing and gluten-free segments of the dog dental care chews market reflect broader trends in pet care, where personalization and health-conscious choices are becoming the norm. As pet owners become more informed and proactive about their pets' health, the demand for specialized products like gluten-free dental chews is expected to rise, contributing to the dynamic growth of the global market.

Online Sales, Offline Sales in the Dog Dental Care Chews - Global Market:

The global market for dog dental care chews is significantly influenced by the channels through which these products are sold, namely online and offline sales. Online sales have seen a remarkable surge in recent years, driven by the convenience and accessibility they offer to consumers. Pet owners can easily browse a wide range of products, compare prices, read reviews, and make purchases from the comfort of their homes. This has been particularly beneficial for those living in remote areas or with busy lifestyles, who may not have easy access to physical pet stores. The rise of e-commerce platforms and the increasing penetration of the internet have further fueled the growth of online sales in the dog dental care chews market. Additionally, online platforms often offer exclusive deals, discounts, and subscription services, making them an attractive option for cost-conscious consumers. On the other hand, offline sales continue to play a crucial role in the distribution of dog dental care chews. Physical stores, including pet specialty stores, veterinary clinics, and supermarkets, provide pet owners with the opportunity to physically examine products before purchasing. This tactile experience is important for many consumers who prefer to assess the quality and suitability of a product firsthand. Moreover, offline sales channels often benefit from the expertise of store staff, who can offer personalized recommendations and advice to pet owners. This human interaction can be a deciding factor for consumers who value expert guidance in choosing the right dental care products for their dogs. The coexistence of online and offline sales channels highlights the diverse preferences of consumers in the dog dental care chews market. While online sales offer convenience and a broad selection, offline sales provide a tangible shopping experience and personalized service. Companies operating in this market are increasingly adopting an omnichannel approach, integrating both online and offline strategies to reach a wider audience. This includes offering click-and-collect services, where consumers can order online and pick up their purchases in-store, combining the benefits of both channels. As the market continues to evolve, it is expected that the synergy between online and offline sales will play a pivotal role in shaping the future of the dog dental care chews market, ensuring that consumers have access to the products they need through their preferred shopping channels.

Dog Dental Care Chews - Global Market Outlook:

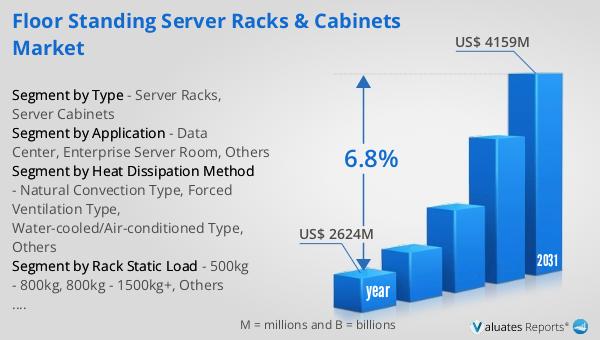

The global market outlook for dog dental care chews is promising, reflecting a broader trend in the pet care industry. According to our research, the global market for medical devices is valued at approximately US$ 603 billion in 2023, with an anticipated compound annual growth rate (CAGR) of 5% over the next six years. This growth trajectory is indicative of the increasing demand for innovative and effective pet care solutions, including dental care products. As pet ownership continues to rise worldwide, so does the awareness of the importance of maintaining pets' oral health. This has led to a surge in demand for products like dog dental care chews, which offer a convenient and effective way to support dental hygiene. The market is characterized by a diverse range of products, catering to different dog sizes, breeds, and specific dental needs. Manufacturers are investing in research and development to create chews that are not only effective but also appealing in taste and texture to encourage regular use by dogs. The emphasis on preventive healthcare and the growing focus on pet wellness are key drivers of this market's growth. Additionally, the convenience of these products makes them a popular choice among pet owners who seek easy-to-use solutions for maintaining their dogs' dental health. As the market continues to expand, it is expected that both gluten-containing and gluten-free options will coexist, providing pet owners with a wide range of choices to suit their dogs' individual needs. The emphasis on transparency and quality in ingredient sourcing is also becoming increasingly important, as consumers seek assurance that the products they purchase are safe and beneficial for their pets. This trend is likely to influence the marketing strategies of companies, as they highlight the health benefits and ingredient integrity of their products to attract discerning pet owners. Overall, the global market for dog dental care chews is poised for significant growth, driven by the increasing awareness of pet health and the demand for innovative and effective dental care solutions.

| Report Metric | Details |

| Report Name | Dog Dental Care Chews - Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Purina, Boehringer Ingelheim Animal Health, Tartar Shield, Milk-Bone, Pedigree, Oven-Baked Tradition, Greenies, Wellness Pet Company, Natural Dog Company, Indigenous Pet, Whimzees, Ilio Products, Merrick, ORAVET |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |