What is Global Ultra High Molecular Weight Acrylic Processing Aid Market?

The Global Ultra High Molecular Weight Acrylic Processing Aid Market is a specialized segment within the broader chemical industry, focusing on the production and application of acrylic processing aids with ultra-high molecular weight. These aids are crucial in enhancing the processing characteristics of various polymer products, particularly in the realm of PVC (polyvinyl chloride) manufacturing. By improving the melt strength and surface quality of PVC products, these aids play a vital role in ensuring the efficiency and quality of the final products. The market is driven by the increasing demand for high-performance materials in construction, automotive, and packaging industries, where durability and quality are paramount. Additionally, the growing trend towards sustainable and efficient manufacturing processes further propels the demand for these processing aids. As industries continue to seek materials that offer superior performance while minimizing environmental impact, the Global Ultra High Molecular Weight Acrylic Processing Aid Market is poised for significant growth. This market not only supports the production of high-quality PVC products but also contributes to the advancement of manufacturing technologies that prioritize both performance and sustainability.

Universal processing aids, Lubrication type processing aid, Efficient processing aids, Others in the Global Ultra High Molecular Weight Acrylic Processing Aid Market:

Universal processing aids are a cornerstone of the Global Ultra High Molecular Weight Acrylic Processing Aid Market, offering versatile solutions that enhance the processing of a wide range of polymer products. These aids are designed to improve the flow and fusion of PVC compounds, ensuring that the final products exhibit superior surface quality and mechanical properties. By facilitating better dispersion of fillers and pigments, universal processing aids help manufacturers achieve consistent product quality, which is crucial in industries such as construction and automotive where precision and reliability are key. Lubrication type processing aids, on the other hand, focus on reducing friction during the processing of polymers. This reduction in friction not only enhances the efficiency of the manufacturing process but also extends the lifespan of processing equipment by minimizing wear and tear. These aids are particularly beneficial in high-speed production environments where maintaining equipment integrity is essential. Efficient processing aids are tailored to optimize the overall processing performance of polymers, focusing on enhancing melt strength and stability. These aids are instrumental in producing complex shapes and profiles, as they allow for greater control over the extrusion process. By improving the melt elasticity of PVC compounds, efficient processing aids enable manufacturers to produce intricate designs with precision and consistency. Other types of processing aids within this market cater to specific needs, such as improving the impact resistance or weatherability of the final products. These specialized aids are crucial in applications where the end products are exposed to harsh environmental conditions or require additional durability. Overall, the diverse range of processing aids available in the Global Ultra High Molecular Weight Acrylic Processing Aid Market underscores the importance of tailored solutions in meeting the specific demands of various industries. By offering a comprehensive suite of processing aids, this market supports the production of high-quality polymer products that meet the evolving needs of modern manufacturing.

Foam Pipes, Foam Sheets, Foam Profiles, Others in the Global Ultra High Molecular Weight Acrylic Processing Aid Market:

The usage of Global Ultra High Molecular Weight Acrylic Processing Aid Market extends across various applications, including foam pipes, foam sheets, foam profiles, and other related products. In the production of foam pipes, these processing aids play a crucial role in enhancing the melt strength and stability of the PVC compounds used. This ensures that the pipes exhibit excellent dimensional stability and surface finish, which are essential for applications in plumbing and construction. The improved processing characteristics also allow for the production of pipes with complex geometries, meeting the diverse needs of the industry. Foam sheets, another significant application area, benefit from the use of these processing aids by achieving uniform cell structure and enhanced surface quality. This is particularly important in packaging and insulation applications, where the performance and appearance of the foam sheets are critical. The aids facilitate better control over the extrusion process, resulting in sheets that are not only aesthetically pleasing but also offer superior thermal and acoustic insulation properties. Foam profiles, used in a variety of applications such as window frames and decorative moldings, also rely on these processing aids to achieve precise shapes and consistent quality. The aids improve the melt elasticity of the PVC compounds, allowing for the production of intricate profiles with sharp details and smooth surfaces. This is essential in applications where the visual appeal and dimensional accuracy of the profiles are paramount. Beyond these specific applications, the Global Ultra High Molecular Weight Acrylic Processing Aid Market also supports the production of other foam products, such as gaskets and seals, where enhanced processing characteristics translate to better performance and durability. By improving the overall processing efficiency and product quality, these aids contribute to the advancement of foam manufacturing technologies, enabling the production of high-performance products that meet the stringent demands of modern industries.

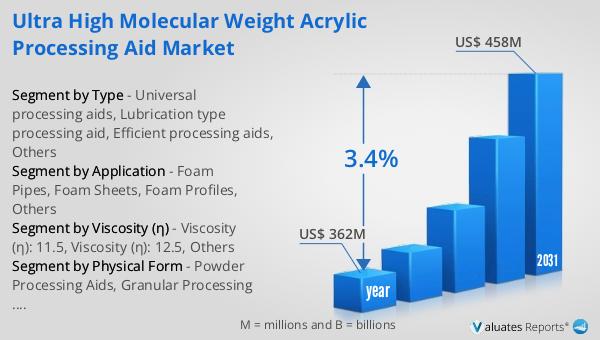

Global Ultra High Molecular Weight Acrylic Processing Aid Market Outlook:

The global market for Ultra High Molecular Weight Acrylic Processing Aid was valued at $362 million in 2024 and is anticipated to grow to a revised size of $458 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.4% over the forecast period. This growth trajectory underscores the increasing demand for high-performance processing aids in various industries, driven by the need for enhanced product quality and manufacturing efficiency. As industries continue to evolve, the demand for materials that offer superior performance while minimizing environmental impact is expected to rise, further propelling the growth of this market. The projected growth also highlights the importance of innovation and technological advancements in the development of processing aids that meet the specific needs of different applications. By focusing on sustainability and efficiency, the Global Ultra High Molecular Weight Acrylic Processing Aid Market is well-positioned to support the production of high-quality polymer products that align with the evolving demands of modern manufacturing. This market outlook not only reflects the current trends but also emphasizes the potential for future growth as industries continue to prioritize performance and sustainability in their manufacturing processes.

| Report Metric | Details |

| Report Name | Ultra High Molecular Weight Acrylic Processing Aid Market |

| Accounted market size in year | US$ 362 million |

| Forecasted market size in 2031 | US$ 458 million |

| CAGR | 3.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Physical Form |

|

| Segment by Viscosity (η) |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Dow, Kaneka, Akdeniz Chemson, RUIFENG CHEM, Shandong He Qi Cheng New Material Technology, Skaomin Materials India, Sundow Polymers, Shandong Novista Chemicals, Shandong Yusu New Material, REPOLYFINE |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |