What is Global Continuous Fiber Reinforced Nylon Composites Market?

The Global Continuous Fiber Reinforced Nylon Composites Market is a specialized segment within the broader composites industry, focusing on materials that combine nylon with continuous fibers to enhance performance characteristics. These composites are engineered to offer superior strength, durability, and resistance to environmental factors compared to traditional materials. The continuous fibers, often made from glass, carbon, or aramid, are embedded within a nylon matrix, providing structural reinforcement. This combination results in a material that is lightweight yet incredibly strong, making it ideal for applications where weight reduction without compromising strength is crucial. Industries such as automotive, aerospace, electronics, and sports equipment manufacturing are increasingly adopting these composites due to their ability to improve fuel efficiency, reduce emissions, and enhance overall product performance. The market is driven by technological advancements, increasing demand for lightweight materials, and the growing emphasis on sustainability. As industries continue to seek materials that offer a balance between performance and environmental impact, the Global Continuous Fiber Reinforced Nylon Composites Market is poised for significant growth, offering innovative solutions to meet the evolving needs of various sectors.

Long Carbon Fiber, Short Carbon Fiber in the Global Continuous Fiber Reinforced Nylon Composites Market:

In the realm of Global Continuous Fiber Reinforced Nylon Composites, Long Carbon Fiber and Short Carbon Fiber play pivotal roles, each offering distinct advantages and applications. Long Carbon Fiber Reinforced Nylon Composites are characterized by fibers that extend continuously throughout the material, providing exceptional strength and stiffness. This continuous alignment of fibers allows for efficient load transfer, making these composites ideal for structural applications where high strength-to-weight ratios are essential. Industries such as aerospace and automotive benefit significantly from long carbon fiber composites, as they contribute to weight reduction while maintaining structural integrity. These composites are often used in components like aircraft wings, automotive body panels, and high-performance sports equipment, where durability and performance are paramount. On the other hand, Short Carbon Fiber Reinforced Nylon Composites consist of shorter, randomly oriented fibers within the nylon matrix. While they may not offer the same level of strength as their long fiber counterparts, they provide excellent impact resistance and are easier to process, making them suitable for complex shapes and intricate designs. These composites are commonly used in applications where flexibility and toughness are required, such as electronic housings, consumer goods, and certain automotive parts. The choice between long and short carbon fiber composites depends on the specific requirements of the application, including factors like load-bearing capacity, design complexity, and cost considerations. As the demand for lightweight, high-performance materials continues to grow, both long and short carbon fiber reinforced nylon composites are expected to play crucial roles in advancing various industries. The versatility of these materials, combined with ongoing research and development efforts, ensures that they will remain at the forefront of innovation, offering solutions that meet the diverse needs of modern manufacturing and engineering.

Automotive, Aerospace, Electronic, Sports, Other in the Global Continuous Fiber Reinforced Nylon Composites Market:

The Global Continuous Fiber Reinforced Nylon Composites Market finds extensive usage across various industries, each leveraging the unique properties of these materials to enhance product performance and efficiency. In the automotive sector, these composites are increasingly used to manufacture lightweight components that contribute to improved fuel efficiency and reduced emissions. Parts such as engine covers, air intake manifolds, and structural components benefit from the strength and durability of continuous fiber reinforced nylon composites, allowing manufacturers to meet stringent regulatory standards while delivering high-performance vehicles. In the aerospace industry, the demand for materials that offer a high strength-to-weight ratio is paramount. Continuous fiber reinforced nylon composites are used in the production of aircraft components such as fuselage panels, wing structures, and interior parts. These materials help reduce the overall weight of the aircraft, leading to enhanced fuel efficiency and reduced operational costs. The electronics industry also benefits from these composites, particularly in the production of lightweight, durable housings for electronic devices. The impact resistance and thermal stability of continuous fiber reinforced nylon composites make them ideal for protecting sensitive electronic components from environmental factors and mechanical stress. In the sports industry, the demand for high-performance equipment drives the use of these composites in products such as bicycles, tennis rackets, and protective gear. The lightweight nature of the materials allows athletes to achieve better performance while maintaining safety and durability. Additionally, other industries, including construction and consumer goods, are exploring the potential of continuous fiber reinforced nylon composites to develop innovative products that meet the evolving needs of consumers. As industries continue to prioritize sustainability and performance, the Global Continuous Fiber Reinforced Nylon Composites Market is poised to play a critical role in shaping the future of manufacturing and product development.

Global Continuous Fiber Reinforced Nylon Composites Market Outlook:

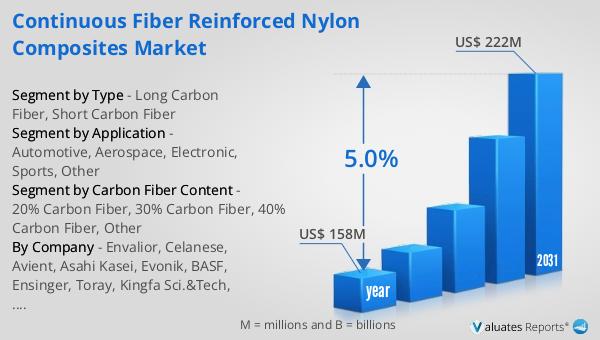

The global market for Continuous Fiber Reinforced Nylon Composites was valued at $158 million in 2024, with projections indicating a growth to $222 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.0% over the forecast period. This growth trajectory underscores the increasing demand for advanced materials that offer a blend of strength, durability, and lightweight properties. The market's expansion is driven by the rising adoption of these composites across various industries, including automotive, aerospace, electronics, and sports, where the need for materials that enhance performance while reducing environmental impact is paramount. The continuous fiber reinforced nylon composites offer a unique combination of properties that make them suitable for a wide range of applications, from structural components in vehicles and aircraft to protective housings for electronic devices. As industries continue to innovate and seek sustainable solutions, the demand for these composites is expected to rise, contributing to the market's growth. The projected increase in market size reflects the ongoing advancements in material science and the growing recognition of the benefits that continuous fiber reinforced nylon composites offer in terms of performance, efficiency, and sustainability. As the market evolves, it will likely see further innovations and applications, solidifying its position as a key player in the global composites industry.

| Report Metric | Details |

| Report Name | Continuous Fiber Reinforced Nylon Composites Market |

| Accounted market size in year | US$ 158 million |

| Forecasted market size in 2031 | US$ 222 million |

| CAGR | 5.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Carbon Fiber Content |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Envalior, Celanese, Avient, Asahi Kasei, Evonik, BASF, Ensinger, Toray, Kingfa Sci.&Tech, Zhuzhou Times Engineering Plastics Technology, Jiangsu QIYI TECHNOLOGIES |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |