What is Global Fibre-reinforced Plastic Tanks and Vessels Market?

The Global Fibre-reinforced Plastic (FRP) Tanks and Vessels Market is a dynamic and rapidly evolving sector that plays a crucial role in various industries worldwide. These tanks and vessels are primarily made from composite materials that combine a polymer matrix with reinforcing fibers, typically glass or carbon. This combination results in a product that is both lightweight and incredibly strong, making it ideal for storing and transporting a wide range of substances. The market for these products is driven by their superior corrosion resistance, durability, and cost-effectiveness compared to traditional materials like steel or concrete. Industries such as chemical processing, water and wastewater treatment, and oil and gas are major consumers of FRP tanks and vessels due to their ability to withstand harsh environments and corrosive substances. As industries continue to seek sustainable and efficient solutions, the demand for FRP tanks and vessels is expected to grow, driven by technological advancements and increasing awareness of their benefits. The market is characterized by a diverse range of products, each tailored to specific applications, and is supported by a robust supply chain that includes raw material suppliers, manufacturers, and distributors.

Filament-Wound FRP Vessels, Hand-Layup/Centrifugal Cast FRP Tanks, Pultruded Composite Vessels, Molded/Injection/Compression Molded FRP Vessels in the Global Fibre-reinforced Plastic Tanks and Vessels Market:

Filament-wound FRP vessels are a significant segment within the Global Fibre-reinforced Plastic Tanks and Vessels Market. These vessels are manufactured using a process where continuous strands of fiber are wound around a rotating mandrel in a specific pattern. This method allows for precise control over the thickness and strength of the vessel walls, resulting in a product that is both lightweight and exceptionally strong. Filament-wound vessels are particularly well-suited for high-pressure applications and are commonly used in industries such as chemical processing and water treatment. The ability to customize the winding pattern and fiber orientation allows manufacturers to tailor the mechanical properties of the vessel to meet specific requirements, making them a versatile choice for a wide range of applications. Hand-layup and centrifugal cast FRP tanks, on the other hand, are produced using more traditional methods. The hand-layup process involves manually applying layers of resin and reinforcing fibers to a mold, while centrifugal casting involves spinning a mold at high speeds to distribute the resin and fibers evenly. These methods are typically used for larger tanks and vessels where precise control over the manufacturing process is less critical. Hand-layup tanks are often used in applications where chemical resistance is a priority, while centrifugal cast tanks are favored for their uniform wall thickness and structural integrity. Pultruded composite vessels are another important category within the market. Pultrusion is a continuous manufacturing process that involves pulling fibers through a resin bath and then through a heated die to form a solid, continuous profile. This method is ideal for producing long, straight sections of FRP, making it well-suited for applications such as piping and structural supports. Pultruded vessels are known for their high strength-to-weight ratio and excellent corrosion resistance, making them a popular choice in industries such as oil and gas and marine. Molded, injection, and compression molded FRP vessels are produced using techniques that involve shaping the composite material in a mold under heat and pressure. These methods are typically used for smaller, more complex shapes where precision and repeatability are important. Molded FRP vessels are often used in applications where tight tolerances and intricate designs are required, such as in the automotive and aerospace industries. Each of these manufacturing methods offers unique advantages and is suited to different applications, allowing the Global Fibre-reinforced Plastic Tanks and Vessels Market to cater to a wide range of industrial needs.

Chemical, Water & Wastewater, Oil & Gas, Others in the Global Fibre-reinforced Plastic Tanks and Vessels Market:

The usage of Global Fibre-reinforced Plastic Tanks and Vessels Market spans several key industries, each with its own specific requirements and challenges. In the chemical industry, FRP tanks and vessels are highly valued for their exceptional resistance to corrosive substances. Chemicals such as acids, alkalis, and solvents can quickly degrade traditional materials like steel, leading to costly maintenance and replacement. FRP tanks, with their superior corrosion resistance, offer a more durable and cost-effective solution. They are used for storing and processing a wide range of chemicals, ensuring safety and reliability in operations. In the water and wastewater industry, FRP tanks and vessels are used extensively for their ability to withstand harsh environmental conditions. They are employed in applications such as water storage, sewage treatment, and desalination, where exposure to moisture and chemicals is a constant challenge. The lightweight nature of FRP tanks also makes them easier to transport and install, reducing overall project costs. In the oil and gas sector, FRP tanks and vessels are used for a variety of applications, including storage of crude oil, natural gas, and refined products. The harsh conditions of oil and gas operations, including exposure to saltwater, chemicals, and extreme temperatures, make FRP an ideal material choice. Its resistance to corrosion and ability to withstand high pressures ensure the safe and efficient storage and transport of valuable resources. Beyond these primary industries, FRP tanks and vessels are also used in a range of other applications. In the food and beverage industry, they are used for storing and processing ingredients and products, thanks to their non-reactive nature and ease of cleaning. In the pharmaceutical industry, FRP vessels are used for the production and storage of sensitive compounds, where contamination must be minimized. The versatility and adaptability of FRP tanks and vessels make them a valuable asset in any industry where durability, safety, and cost-effectiveness are priorities.

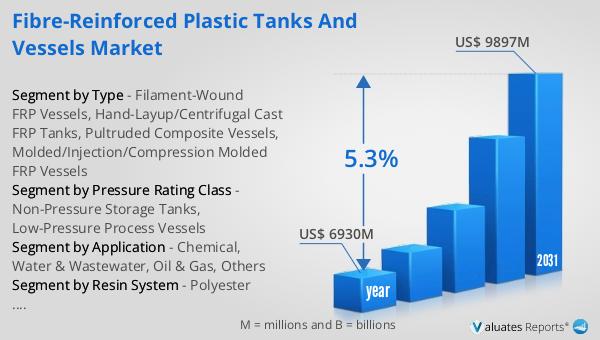

Global Fibre-reinforced Plastic Tanks and Vessels Market Outlook:

The global market for Fibre-reinforced Plastic Tanks and Vessels was valued at $6,930 million in 2024, and it is anticipated to grow significantly over the coming years. By 2031, the market is projected to reach a revised size of $9,897 million, reflecting a compound annual growth rate (CAGR) of 5.3% during the forecast period. This growth can be attributed to several factors, including the increasing demand for durable and corrosion-resistant materials across various industries. As companies continue to seek out cost-effective and sustainable solutions, the advantages of FRP tanks and vessels become increasingly apparent. Their lightweight nature, combined with their strength and resistance to harsh chemicals and environmental conditions, makes them an attractive option for industries ranging from chemical processing to oil and gas. The market's expansion is also supported by ongoing advancements in manufacturing technologies, which allow for greater customization and efficiency in production. As a result, the Global Fibre-reinforced Plastic Tanks and Vessels Market is poised for continued growth, driven by the need for innovative and reliable storage solutions in an ever-evolving industrial landscape.

| Report Metric | Details |

| Report Name | Fibre-reinforced Plastic Tanks and Vessels Market |

| Accounted market size in year | US$ 6930 million |

| Forecasted market size in 2031 | US$ 9897 million |

| CAGR | 5.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Resin System |

|

| Segment by Pressure Rating Class |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Sainath Industrial Corporation (SIC), Plas-Tank Industries Inc., Augusta Fiberglass Coating Inc, TROY Dualam Inc., Swami Plastic Industries, FGPL, NOV Fiber Glass Systems, Tecnium, Diamond Fiberglass Inc, EPP Composites Pvt Ltd, Lianyungang Zhongfu Lianzhong Composites Group Co, HA-CO Carbon GmbH, Colasit, FORBES GROUP |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |