What is Global Sponge Rubber Seals Market?

The Global Sponge Rubber Seals Market is a specialized segment within the broader rubber industry, focusing on the production and distribution of seals made from sponge rubber. These seals are essential components in various industries due to their unique properties, such as flexibility, compressibility, and resistance to environmental factors like moisture and temperature fluctuations. Sponge rubber seals are used to prevent the passage of air, dust, water, and other elements, making them crucial for maintaining the integrity and efficiency of systems and structures. The market for these seals is driven by the demand from industries such as automotive, construction, electronics, and aerospace, where they are used to enhance performance and durability. The global market is characterized by a diverse range of products, including open-cell, closed-cell, and mixed-cell sponge rubber seals, each offering distinct advantages depending on the application. As industries continue to seek materials that offer better performance and sustainability, the demand for sponge rubber seals is expected to grow, driven by technological advancements and the need for more efficient sealing solutions. The market's growth is also supported by the increasing focus on energy efficiency and environmental regulations, which require high-quality sealing solutions to reduce energy loss and emissions.

Open-cell Sponge Rubber, Closed-cell Sponge Rubber, Mixed-cell Sponge Rubber in the Global Sponge Rubber Seals Market:

Open-cell sponge rubber, closed-cell sponge rubber, and mixed-cell sponge rubber are three primary types of sponge rubber used in the global sponge rubber seals market, each offering unique characteristics and benefits. Open-cell sponge rubber is characterized by its interconnected cell structure, which allows air and moisture to pass through. This type of sponge rubber is highly compressible and flexible, making it ideal for applications where cushioning and shock absorption are required. It is commonly used in industries such as automotive and electronics, where it serves as a gasket or seal to dampen vibrations and reduce noise. The open-cell structure also makes it suitable for applications where breathability is important, such as in certain types of filters and padding. Closed-cell sponge rubber, on the other hand, features a structure where the cells are completely enclosed, preventing the passage of air and moisture. This makes closed-cell sponge rubber highly resistant to water and other environmental factors, making it ideal for outdoor applications and environments where moisture resistance is critical. It is widely used in the construction industry for sealing and insulation purposes, as well as in the automotive industry for weatherstripping and sealing components. The closed-cell structure provides excellent thermal insulation and is often used in applications where energy efficiency is a priority. Mixed-cell sponge rubber combines the properties of both open-cell and closed-cell structures, offering a balance of flexibility, compressibility, and resistance to environmental factors. This type of sponge rubber is versatile and can be used in a wide range of applications, providing both cushioning and sealing capabilities. It is often used in industries where a combination of properties is required, such as in the aerospace industry, where it is used for sealing and insulation in aircraft components. The global sponge rubber seals market benefits from the diverse range of products available, allowing industries to select the most suitable type of sponge rubber for their specific needs. As technology advances and the demand for more efficient and sustainable materials grows, the development of new formulations and manufacturing techniques for sponge rubber is expected to continue, further enhancing the performance and application range of these versatile materials.

Construction, Automotive, Electronics, Aerospace, Others in the Global Sponge Rubber Seals Market:

The usage of sponge rubber seals in various industries highlights their versatility and importance in maintaining the efficiency and integrity of systems and structures. In the construction industry, sponge rubber seals are used extensively for sealing and insulation purposes. They help prevent the ingress of air, water, and dust, ensuring that buildings are energy-efficient and protected from environmental elements. These seals are commonly used in windows, doors, and HVAC systems, where they provide a barrier against external conditions and help maintain indoor comfort. In the automotive industry, sponge rubber seals play a crucial role in enhancing vehicle performance and comfort. They are used in weatherstripping, gaskets, and seals to prevent the entry of water, dust, and noise into the vehicle cabin. This not only improves the driving experience but also protects the vehicle's interior components from damage. Sponge rubber seals are also used in engine compartments and other critical areas to ensure proper sealing and reduce the risk of leaks and malfunctions. In the electronics industry, sponge rubber seals are used to protect sensitive components from dust, moisture, and other contaminants. They are often used in enclosures and casings to ensure that electronic devices operate reliably and have a longer lifespan. The aerospace industry also relies on sponge rubber seals for their lightweight and durable properties. These seals are used in aircraft components to provide insulation, reduce noise, and ensure the integrity of critical systems. The ability of sponge rubber seals to withstand extreme temperatures and environmental conditions makes them ideal for aerospace applications. Beyond these industries, sponge rubber seals are used in a variety of other applications, including medical devices, appliances, and industrial machinery. Their versatility and adaptability make them a valuable component in any application where sealing, insulation, and protection are required. As industries continue to evolve and demand more efficient and sustainable materials, the usage of sponge rubber seals is expected to grow, driven by their ability to meet the diverse needs of modern applications.

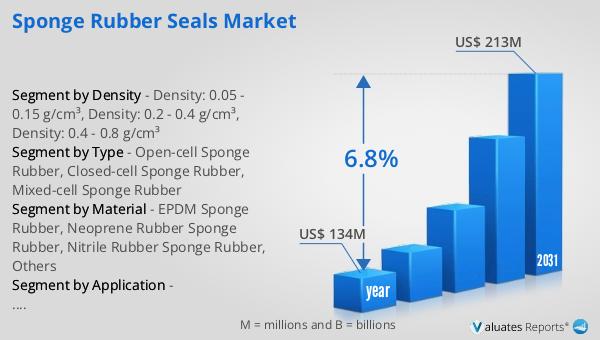

Global Sponge Rubber Seals Market Outlook:

In 2024, the global sponge rubber seals market was valued at approximately $134 million. This market is anticipated to experience significant growth over the coming years, with projections indicating that it will reach around $213 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.8% during the forecast period. The increasing demand for sponge rubber seals across various industries, including automotive, construction, electronics, and aerospace, is a key driver of this growth. These seals are essential for ensuring the efficiency and integrity of systems by preventing the ingress of air, water, dust, and other contaminants. As industries continue to prioritize energy efficiency and environmental sustainability, the demand for high-quality sealing solutions is expected to rise. Technological advancements and the development of new formulations and manufacturing techniques for sponge rubber are also contributing to the market's expansion. The versatility and adaptability of sponge rubber seals make them a valuable component in a wide range of applications, further supporting their growing demand. As the market continues to evolve, companies are likely to focus on innovation and product development to meet the changing needs of their customers and capitalize on the opportunities presented by this expanding market.

| Report Metric | Details |

| Report Name | Sponge Rubber Seals Market |

| Accounted market size in year | US$ 134 million |

| Forecasted market size in 2031 | US$ 213 million |

| CAGR | 6.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Material |

|

| Segment by Density |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | W. KÖPP GmbH & Co. KG, Exactseal, Alanto, SantopSeal Corporation, Rehm Dichtungen Ehlers GmbH, Elastostar Rubber Corporation, AJ Rubber, HEBEI SHIDA SEA GROUP CO.LTD, Kinsoe, Letu Automotive, Custom Gasket Mfg., ZHONGXIANG, Accuseal Rubber Inc., Walker Rubber, Seashore Rubber |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |