What is Pharmaceutical Mixer Machine - Global Market?

Pharmaceutical mixer machines are essential equipment in the global pharmaceutical industry, designed to blend various ingredients to create medications. These machines ensure that the active pharmaceutical ingredients (APIs) and excipients are mixed uniformly, which is crucial for the efficacy and safety of the final product. The global market for pharmaceutical mixer machines is driven by the increasing demand for pharmaceuticals, advancements in technology, and the need for efficient and reliable mixing solutions. These machines come in various types and sizes, catering to different production scales and requirements. They are used in the production of tablets, capsules, syrups, and other pharmaceutical forms. The market is characterized by continuous innovation, with manufacturers focusing on developing machines that offer better precision, speed, and energy efficiency. As the pharmaceutical industry continues to grow, the demand for advanced mixer machines is expected to rise, making it a vital component of the global pharmaceutical manufacturing landscape.

Vertical, Horizontal in the Pharmaceutical Mixer Machine - Global Market:

In the realm of pharmaceutical mixer machines, two primary configurations are prevalent: vertical and horizontal mixers. Each type has its unique design and operational advantages, catering to different needs within the pharmaceutical manufacturing process. Vertical mixers are typically characterized by their upright design, where the mixing vessel is positioned vertically. This design is particularly advantageous for processes that require gravity-assisted mixing, as the vertical orientation allows for efficient movement of materials from top to bottom. Vertical mixers are often used in applications where gentle mixing is required, as the design minimizes shear forces that could potentially degrade sensitive ingredients. These mixers are also known for their space-saving design, making them suitable for facilities with limited floor space. On the other hand, horizontal mixers feature a horizontally oriented mixing vessel, which allows for more aggressive mixing actions. This design is ideal for processes that require thorough blending of ingredients, as the horizontal orientation facilitates the movement of materials across the entire length of the mixing chamber. Horizontal mixers are often equipped with various types of mixing blades or paddles, which can be customized to suit specific mixing requirements. This versatility makes them suitable for a wide range of pharmaceutical applications, from blending powders to mixing viscous liquids. The choice between vertical and horizontal mixers often depends on the specific requirements of the production process, including the nature of the ingredients being mixed, the desired mixing speed, and the available space within the manufacturing facility. Both types of mixers play a crucial role in ensuring the uniformity and quality of pharmaceutical products, contributing to the overall efficiency and effectiveness of the manufacturing process. As the pharmaceutical industry continues to evolve, the demand for advanced mixing solutions is expected to grow, driving further innovation and development in the design and functionality of both vertical and horizontal mixers.

Batch Production, R&D in the Pharmaceutical Mixer Machine - Global Market:

Pharmaceutical mixer machines are indispensable in various stages of drug production, particularly in batch production and research and development (R&D). In batch production, these machines are used to mix large quantities of ingredients to produce a specific batch of pharmaceutical products. The primary goal in batch production is to ensure consistency and uniformity across all units of the product. Mixer machines play a critical role in achieving this by providing precise control over the mixing process, ensuring that each batch meets the required quality standards. The ability to replicate the same mixing conditions for each batch is crucial in maintaining the efficacy and safety of the pharmaceutical products. In the context of R&D, pharmaceutical mixer machines are used to develop and test new formulations. During the R&D phase, small-scale mixers are often employed to experiment with different ingredient combinations and mixing techniques. These machines allow researchers to fine-tune the mixing process, optimizing the formulation for maximum effectiveness and stability. The insights gained during the R&D phase are invaluable in scaling up the production process, as they provide a foundation for developing efficient and reliable mixing protocols. The versatility and precision of pharmaceutical mixer machines make them essential tools in both batch production and R&D, supporting the development and manufacture of high-quality pharmaceutical products. As the pharmaceutical industry continues to innovate and expand, the demand for advanced mixer machines is expected to increase, further highlighting their importance in the global market.

Pharmaceutical Mixer Machine - Global Market Outlook:

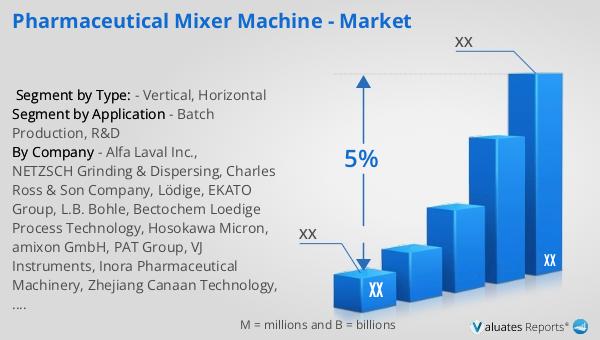

The global pharmaceutical market was valued at approximately 1,475 billion USD in 2022, with projections indicating a steady growth rate of 5% annually over the next six years. This growth is indicative of the increasing demand for pharmaceutical products worldwide, driven by factors such as an aging population, rising prevalence of chronic diseases, and advancements in medical technology. In comparison, the chemical drug market has shown a more modest growth trajectory, expanding from 1,005 billion USD in 2018 to an estimated 1,094 billion USD in 2022. This growth reflects the ongoing demand for chemical-based medications, which continue to play a significant role in the treatment of various health conditions. The pharmaceutical mixer machine market is intrinsically linked to these broader market trends, as the demand for efficient and reliable mixing solutions is directly influenced by the overall growth of the pharmaceutical industry. As pharmaceutical companies strive to meet the increasing demand for medications, the need for advanced mixer machines that can ensure the quality and consistency of their products becomes more critical. This underscores the importance of continued innovation and development in the pharmaceutical mixer machine market, as manufacturers seek to provide solutions that meet the evolving needs of the industry.

| Report Metric | Details |

| Report Name | Pharmaceutical Mixer Machine - Market |

| CAGR | 5% |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Alfa Laval Inc., NETZSCH Grinding & Dispersing, Charles Ross & Son Company, Lödige, EKATO Group, L.B. Bohle, Bectochem Loedige Process Technology, Hosokawa Micron, amixon GmbH, PAT Group, VJ Instruments, Inora Pharmaceutical Machinery, Zhejiang Canaan Technology, Dec Group, LFA Machines, IPharmachine, SaintyCo, Eberbach Corporation, WAMGroup, Yenchen Machinery, Prism Pharma Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |