What is Global Carbon Fiber Reinforced Plastics (CFRP) Molded Products Market?

The Global Carbon Fiber Reinforced Plastics (CFRP) Molded Products Market is a dynamic and rapidly evolving sector that plays a crucial role in various industries. CFRP is a composite material made from carbon fibers and a plastic matrix, which provides exceptional strength-to-weight ratio, making it highly desirable for applications where weight reduction is critical without compromising strength. This market encompasses a wide range of products that are molded using CFRP, catering to industries such as aerospace, automotive, wind energy, construction, sports, and leisure. The demand for CFRP molded products is driven by the need for lightweight, durable, and high-performance materials that can withstand extreme conditions. As industries continue to seek innovative solutions to enhance efficiency and sustainability, the CFRP molded products market is poised for significant growth. The versatility of CFRP allows it to be tailored to specific requirements, making it an ideal choice for manufacturers looking to improve product performance and reduce environmental impact. With advancements in manufacturing technologies and increasing awareness of the benefits of CFRP, the market is expected to expand further, offering new opportunities for businesses and consumers alike.

Thermoset CFRP Molded Products, Thermoplastic CFRP Molded Products in the Global Carbon Fiber Reinforced Plastics (CFRP) Molded Products Market:

Thermoset CFRP Molded Products and Thermoplastic CFRP Molded Products are two primary categories within the Global Carbon Fiber Reinforced Plastics (CFRP) Molded Products Market, each with distinct characteristics and applications. Thermoset CFRP products are created using a resin that cures and hardens when heated, resulting in a rigid and durable structure. This type of CFRP is known for its excellent thermal stability, chemical resistance, and ability to maintain structural integrity under high stress. It is commonly used in industries where long-term performance and reliability are paramount, such as aerospace and automotive. The curing process of thermoset CFRP involves a chemical reaction that forms a cross-linked polymer matrix, providing superior mechanical properties and resistance to deformation. On the other hand, Thermoplastic CFRP Molded Products are made using a plastic matrix that softens when heated and hardens upon cooling. This allows for easier processing and reshaping, making thermoplastic CFRP ideal for applications requiring flexibility and recyclability. Thermoplastic CFRP offers advantages such as faster production cycles, potential for mass production, and the ability to be re-melted and reformed, which is beneficial for industries focusing on sustainability and cost-effectiveness. The choice between thermoset and thermoplastic CFRP depends on the specific requirements of the application, including factors such as temperature resistance, mechanical strength, and production volume. In the aerospace industry, thermoset CFRP is often preferred for structural components due to its high strength and stability, while thermoplastic CFRP is used for interior parts where weight reduction and ease of manufacturing are critical. In the automotive sector, both types of CFRP are utilized, with thermoset CFRP being favored for high-performance vehicles and thermoplastic CFRP for mass-produced models. The wind energy sector benefits from the lightweight and durable nature of thermoset CFRP for turbine blades, while the construction industry leverages the versatility of thermoplastic CFRP for building components. Sports and leisure products, such as bicycles and sporting equipment, also take advantage of the lightweight and customizable properties of CFRP, with thermoplastic variants offering additional benefits in terms of design flexibility and recyclability. As the demand for high-performance materials continues to grow, the Global CFRP Molded Products Market is expected to see increased adoption of both thermoset and thermoplastic CFRP, driven by advancements in material science and manufacturing technologies. The ongoing research and development efforts in this field aim to enhance the properties of CFRP, making it more accessible and cost-effective for a wider range of applications.

Aerospace & Defense, Automotive, Wind Energy, Construction Engineering, Sports & Leisure, Other in the Global Carbon Fiber Reinforced Plastics (CFRP) Molded Products Market:

The usage of Global Carbon Fiber Reinforced Plastics (CFRP) Molded Products Market spans across various industries, each benefiting from the unique properties of CFRP. In the Aerospace & Defense sector, CFRP is extensively used for manufacturing aircraft components such as fuselage sections, wings, and tail assemblies. The lightweight nature of CFRP contributes to fuel efficiency and increased payload capacity, while its strength ensures safety and durability under extreme conditions. The automotive industry leverages CFRP for producing lightweight vehicle parts, which help in reducing fuel consumption and emissions. High-performance cars, in particular, utilize CFRP for body panels, chassis, and interior components to enhance speed and agility. In the Wind Energy sector, CFRP is employed in the construction of turbine blades, where its lightweight and high-strength characteristics enable longer and more efficient blades, leading to increased energy capture. The Construction Engineering industry uses CFRP for reinforcing structures, providing an alternative to traditional materials like steel and concrete. CFRP's corrosion resistance and high tensile strength make it ideal for strengthening bridges, buildings, and other infrastructure. In the Sports & Leisure industry, CFRP is used to manufacture equipment such as bicycles, golf clubs, and tennis rackets, where its lightweight and customizable properties enhance performance and user experience. Other industries, including marine and electronics, also benefit from CFRP's versatility and performance advantages. The growing awareness of environmental sustainability and the need for energy-efficient solutions drive the adoption of CFRP across these sectors. As industries continue to innovate and seek materials that offer a balance of performance, durability, and sustainability, the Global CFRP Molded Products Market is poised for significant growth. The ongoing advancements in manufacturing technologies and material science further expand the potential applications of CFRP, making it an increasingly attractive option for a wide range of industries.

Global Carbon Fiber Reinforced Plastics (CFRP) Molded Products Market Outlook:

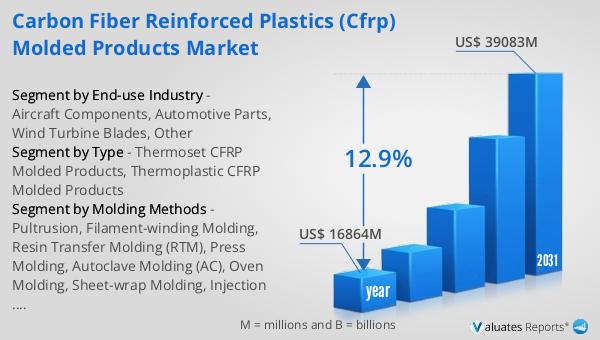

The global market for Carbon Fiber Reinforced Plastics (CFRP) Molded Products was valued at $16,864 million in 2024 and is anticipated to grow significantly, reaching an estimated size of $39,083 million by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 12.9% over the forecast period. This impressive expansion underscores the increasing demand for CFRP molded products across various industries, driven by the need for lightweight, durable, and high-performance materials. The aerospace, automotive, and wind energy sectors, in particular, are major contributors to this growth, as they continue to seek innovative solutions to enhance efficiency and sustainability. The versatility of CFRP, combined with advancements in manufacturing technologies, is expected to further propel the market's expansion. As industries prioritize reducing environmental impact and improving product performance, the CFRP molded products market is well-positioned to meet these demands. The projected growth also highlights the potential for new opportunities and applications, as businesses and consumers alike recognize the benefits of CFRP in achieving their goals. With a focus on sustainability and performance, the Global CFRP Molded Products Market is set to play a pivotal role in shaping the future of various industries.

| Report Metric | Details |

| Report Name | Carbon Fiber Reinforced Plastics (CFRP) Molded Products Market |

| Accounted market size in year | US$ 16864 million |

| Forecasted market size in 2031 | US$ 39083 million |

| CAGR | 12.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by End-use Industry |

|

| Segment by Molding Methods |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Spirit AeroSystems, GKN Aerospace, FACC AG, Hexcel, Applied Composites, Kaman Composites, Royal Engineered Composites, Nammo Composite Solutions, FDC Aero Composites, Terma, Alestis Aerospace, SGL Carbon, Aerodine Composites, Composiflex, Heico Corporation, CSP (Teijin Automotive Technologies), Mubea, ACTION COMPOSITES, Toray, MCCFC, Carbon Revolution, Ensinger, Sika, Hankuk Carbon, Weihai Guangwei Composites, HRC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |