What is Global Automotive Carbon Fiber Reinforced Plastic (CFRP) Components Market?

The Global Automotive Carbon Fiber Reinforced Plastic (CFRP) Components Market is a dynamic and rapidly evolving sector within the automotive industry. Carbon Fiber Reinforced Plastic, or CFRP, is a composite material known for its high strength-to-weight ratio, making it an ideal choice for automotive applications where reducing weight without compromising strength is crucial. This market encompasses a wide range of components used in vehicles, from body panels and chassis parts to interior components and more. The demand for CFRP components is driven by the automotive industry's ongoing pursuit of fuel efficiency, performance enhancement, and emission reduction. As governments worldwide implement stricter environmental regulations, automakers are increasingly turning to lightweight materials like CFRP to meet these standards. Additionally, the growing popularity of electric vehicles, which require lightweight materials to maximize battery efficiency, further fuels the demand for CFRP components. The market is characterized by continuous innovation, with manufacturers investing in research and development to improve the production processes and cost-effectiveness of CFRP components. As a result, the Global Automotive CFRP Components Market is poised for significant growth in the coming years, offering exciting opportunities for both established players and new entrants in the industry.

Thermoset CFRP Components, Thermoplastic CFRP Components in the Global Automotive Carbon Fiber Reinforced Plastic (CFRP) Components Market:

Thermoset and thermoplastic CFRP components are two primary categories within the Global Automotive Carbon Fiber Reinforced Plastic (CFRP) Components Market, each with distinct characteristics and applications. Thermoset CFRP components are made using a resin that, once cured, cannot be re-melted or reshaped. This type of CFRP is known for its excellent thermal stability, chemical resistance, and structural integrity, making it ideal for high-performance automotive applications. Thermoset CFRP is commonly used in critical structural components such as chassis parts, suspension systems, and body panels. The curing process for thermoset CFRP involves a chemical reaction that creates a strong, rigid matrix, providing exceptional strength and durability. However, the production process can be time-consuming and costly, which has historically limited its widespread adoption in mass-market vehicles. On the other hand, thermoplastic CFRP components are made using a resin that can be melted and reshaped multiple times. This characteristic offers several advantages, including faster production cycles, easier recyclability, and the ability to create complex shapes. Thermoplastic CFRP is increasingly being used in automotive applications where flexibility, impact resistance, and cost-effectiveness are essential. These components are often found in interior parts, bumpers, and other non-structural elements. The ability to quickly mold and reshape thermoplastic CFRP makes it an attractive option for automakers looking to streamline production and reduce costs. As the automotive industry continues to evolve, the demand for both thermoset and thermoplastic CFRP components is expected to grow. Manufacturers are investing in advanced production techniques and materials to enhance the performance and cost-effectiveness of these components. Innovations such as automated manufacturing processes, improved resin formulations, and hybrid materials are driving the development of next-generation CFRP components. Additionally, collaborations between automakers, material suppliers, and research institutions are fostering the exchange of knowledge and expertise, further accelerating the advancement of CFRP technology. The choice between thermoset and thermoplastic CFRP components often depends on the specific requirements of the application, including factors such as performance, cost, and production volume. As a result, automakers are increasingly adopting a hybrid approach, utilizing both types of CFRP components to optimize vehicle performance and efficiency. This trend is particularly evident in the development of electric and hybrid vehicles, where lightweight materials play a crucial role in extending range and improving overall efficiency. In conclusion, thermoset and thermoplastic CFRP components each offer unique advantages and challenges within the Global Automotive CFRP Components Market. As the industry continues to prioritize lightweighting and sustainability, the demand for these advanced materials is expected to grow, driving innovation and collaboration across the automotive value chain.

Passenger Cars, Commercial Vehicles in the Global Automotive Carbon Fiber Reinforced Plastic (CFRP) Components Market:

The usage of Global Automotive Carbon Fiber Reinforced Plastic (CFRP) Components Market in passenger cars and commercial vehicles is a testament to the material's versatility and performance benefits. In passenger cars, CFRP components are increasingly being used to enhance vehicle performance, safety, and fuel efficiency. The lightweight nature of CFRP allows automakers to reduce the overall weight of the vehicle, leading to improved acceleration, handling, and braking. This is particularly important in sports cars and high-performance vehicles, where every kilogram counts. CFRP is commonly used in body panels, roofs, and hoods, where its strength and rigidity contribute to improved crash safety and structural integrity. Additionally, the aesthetic appeal of carbon fiber, with its distinctive weave pattern, adds a premium touch to luxury vehicles, enhancing their market appeal. In commercial vehicles, the use of CFRP components is driven by the need for durability, fuel efficiency, and payload capacity. Commercial vehicles, such as trucks and buses, benefit from the weight savings offered by CFRP, which translates into increased payload capacity and reduced fuel consumption. This is particularly important in long-haul transportation, where fuel costs represent a significant portion of operating expenses. CFRP components are used in various parts of commercial vehicles, including chassis, body panels, and interior components, where their strength and durability contribute to extended service life and reduced maintenance costs. The adoption of CFRP in commercial vehicles is also driven by regulatory pressures to reduce emissions and improve fuel efficiency. As governments worldwide implement stricter emissions standards, commercial vehicle manufacturers are turning to lightweight materials like CFRP to meet these requirements. The use of CFRP components in both passenger cars and commercial vehicles is supported by ongoing advancements in manufacturing processes and material technology. Innovations such as automated production techniques, improved resin formulations, and hybrid materials are making CFRP more accessible and cost-effective for a wider range of applications. Additionally, collaborations between automakers, material suppliers, and research institutions are fostering the exchange of knowledge and expertise, further accelerating the adoption of CFRP in the automotive industry. In conclusion, the usage of Global Automotive CFRP Components Market in passenger cars and commercial vehicles is driven by the material's unique combination of strength, lightweight, and aesthetic appeal. As the automotive industry continues to prioritize performance, efficiency, and sustainability, the demand for CFRP components is expected to grow, offering exciting opportunities for innovation and collaboration across the value chain.

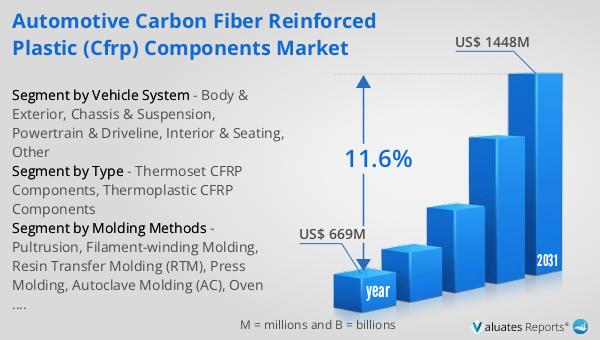

Global Automotive Carbon Fiber Reinforced Plastic (CFRP) Components Market Outlook:

The global market for Automotive Carbon Fiber Reinforced Plastic (CFRP) Components is on a promising growth trajectory. In 2024, the market was valued at approximately $669 million. By 2031, it is anticipated to expand significantly, reaching an estimated size of $1,448 million. This growth is projected to occur at a compound annual growth rate (CAGR) of 11.6% over the forecast period. This robust growth can be attributed to several factors, including the increasing demand for lightweight materials in the automotive industry, driven by the need for improved fuel efficiency and reduced emissions. As automakers strive to meet stringent environmental regulations and consumer demand for high-performance vehicles, the adoption of CFRP components is expected to rise. Additionally, the growing popularity of electric vehicles, which require lightweight materials to maximize battery efficiency, further fuels the demand for CFRP components. The market's expansion is also supported by ongoing advancements in manufacturing processes and material technology, making CFRP more accessible and cost-effective for a wider range of applications. As a result, the Global Automotive CFRP Components Market is poised for significant growth, offering exciting opportunities for both established players and new entrants in the industry.

| Report Metric | Details |

| Report Name | Automotive Carbon Fiber Reinforced Plastic (CFRP) Components Market |

| Accounted market size in year | US$ 669 million |

| Forecasted market size in 2031 | US$ 1448 million |

| CAGR | 11.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Vehicle System |

|

| Segment by Molding Methods |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | CSP (Teijin Automotive Technologies), Mubea, ACTION COMPOSITES, Carbon by Design, SGL Carbon, Toray, MCCFC, Carbon Revolution, Voith Composites, Ensinger, Röchling, Hankuk Carbon, Weihai Guangwei Composites, HRC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |