What is Global Baking Food Packaging Machine Market?

The Global Baking Food Packaging Machine Market refers to the industry that manufactures and sells machines specifically designed for packaging baked goods. These machines are essential for ensuring that baked products such as bread, cakes, pastries, and cookies are packaged efficiently and hygienically. The market encompasses a wide range of machinery, from simple sealing machines to complex systems that can handle multiple packaging tasks simultaneously. These machines help in extending the shelf life of baked goods by protecting them from environmental factors such as moisture, air, and contaminants. The demand for baking food packaging machines is driven by the growing bakery industry, increasing consumer preference for packaged foods, and the need for efficient and cost-effective packaging solutions. As the global population continues to grow and urbanize, the demand for packaged baked goods is expected to rise, further fueling the growth of this market. Technological advancements in packaging machinery, such as automation and the integration of smart technologies, are also contributing to the market's expansion by improving the efficiency and functionality of these machines.

Fully Automatic, Semi-Automatic in the Global Baking Food Packaging Machine Market:

In the Global Baking Food Packaging Machine Market, machines are generally categorized into two main types: fully automatic and semi-automatic. Fully automatic machines are designed to perform packaging tasks with minimal human intervention. These machines are equipped with advanced technologies that allow them to handle various packaging processes such as filling, sealing, labeling, and wrapping. They are ideal for large-scale baking operations where high-speed and high-volume packaging is required. Fully automatic machines offer several advantages, including increased efficiency, reduced labor costs, and consistent packaging quality. They are often integrated with other production line equipment to create a seamless and efficient packaging process. On the other hand, semi-automatic machines require some level of human intervention to operate. These machines are typically used in smaller baking operations or in situations where flexibility and customization are needed. Semi-automatic machines offer the advantage of being more affordable and easier to maintain compared to fully automatic machines. They allow operators to have more control over the packaging process, which can be beneficial for businesses that produce a wide variety of baked goods with different packaging requirements. Both fully automatic and semi-automatic machines play a crucial role in the baking food packaging industry, catering to the diverse needs of bakeries around the world. The choice between fully automatic and semi-automatic machines depends on several factors, including the scale of production, budget, and specific packaging requirements. For large-scale operations, fully automatic machines are often the preferred choice due to their ability to handle high volumes of products efficiently. These machines are equipped with advanced features such as automated product feeding, precise filling and sealing mechanisms, and integrated quality control systems. They can significantly reduce the time and labor required for packaging, allowing bakeries to increase their production capacity and meet the growing demand for packaged baked goods. Additionally, fully automatic machines can be customized to accommodate different packaging formats and sizes, providing bakeries with the flexibility to adapt to changing market trends and consumer preferences. In contrast, semi-automatic machines are more suitable for smaller bakeries or businesses that produce a limited range of products. These machines offer a balance between automation and manual control, allowing operators to adjust the packaging process according to their specific needs. Semi-automatic machines are often used for packaging artisanal or specialty baked goods that require a more hands-on approach. They are also a cost-effective option for businesses that are just starting out or have limited resources. Despite their lower level of automation, semi-automatic machines can still deliver high-quality packaging results, ensuring that baked goods are protected and presented attractively to consumers. In conclusion, the Global Baking Food Packaging Machine Market offers a wide range of options for bakeries looking to improve their packaging processes. Whether a bakery chooses a fully automatic or semi-automatic machine depends on its production needs, budget, and desired level of automation. Both types of machines have their own unique advantages and can contribute to the success of a bakery by enhancing efficiency, reducing costs, and ensuring the quality and safety of packaged baked goods.

Baking Food Factory, Baking Shop, Others in the Global Baking Food Packaging Machine Market:

The Global Baking Food Packaging Machine Market finds its application in various areas, including baking food factories, baking shops, and other related sectors. In baking food factories, these machines are essential for large-scale production and packaging of baked goods. Factories often operate with high production volumes and require efficient packaging solutions to keep up with demand. Baking food packaging machines in factories are typically integrated into the production line, allowing for seamless and continuous packaging processes. These machines help factories maintain high standards of hygiene and quality by ensuring that baked goods are packaged in a controlled environment. The use of advanced technologies in these machines, such as automation and real-time monitoring, enables factories to optimize their packaging operations, reduce waste, and improve overall productivity. In baking shops, packaging machines play a crucial role in enhancing the presentation and shelf life of baked goods. Baking shops often produce a variety of products, from bread and pastries to cakes and cookies, each with its own packaging requirements. Packaging machines in baking shops are used to wrap, seal, and label products, ensuring that they are protected from external factors and remain fresh for consumers. These machines also help baking shops create attractive and professional packaging that can enhance their brand image and attract customers. By investing in packaging machines, baking shops can streamline their operations, reduce manual labor, and focus on creating high-quality baked goods. Beyond factories and shops, the Global Baking Food Packaging Machine Market also serves other sectors such as catering services, food delivery businesses, and retail outlets. In catering services, packaging machines are used to prepare and package baked goods for events and functions, ensuring that they are delivered fresh and in perfect condition. Food delivery businesses rely on packaging machines to package baked goods for transport, protecting them from damage and maintaining their quality during transit. Retail outlets, such as supermarkets and convenience stores, use packaging machines to package baked goods for sale, providing consumers with convenient and ready-to-eat options. The versatility and efficiency of baking food packaging machines make them indispensable in these sectors, helping businesses meet consumer demands and maintain high standards of quality and safety. Overall, the Global Baking Food Packaging Machine Market plays a vital role in the baking industry by providing essential packaging solutions for various applications. Whether in large-scale factories, small baking shops, or other related sectors, these machines help businesses improve their packaging processes, enhance product quality, and meet the growing demand for packaged baked goods. By investing in the right packaging machines, businesses can achieve greater efficiency, reduce costs, and ensure that their products reach consumers in the best possible condition.

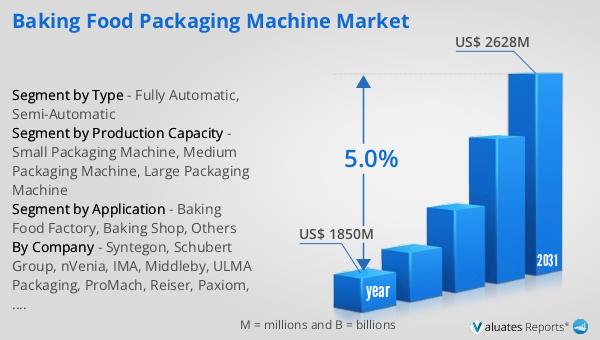

Global Baking Food Packaging Machine Market Outlook:

The global market for Baking Food Packaging Machines was valued at $1.85 billion in 2024 and is anticipated to grow to a revised size of $2.628 billion by 2031, reflecting a compound annual growth rate (CAGR) of 5.0% over the forecast period. This growth trajectory underscores the increasing demand for efficient and advanced packaging solutions in the baking industry. As consumer preferences shift towards packaged and ready-to-eat baked goods, the need for reliable packaging machinery becomes more pronounced. The market's expansion is driven by several factors, including the rising consumption of baked products, technological advancements in packaging machinery, and the growing emphasis on food safety and hygiene. The integration of automation and smart technologies in packaging machines is also contributing to the market's growth by enhancing the efficiency and functionality of these machines. As the market continues to evolve, manufacturers are focusing on developing innovative and sustainable packaging solutions to meet the changing needs of consumers and businesses alike. The projected growth of the Baking Food Packaging Machine Market highlights the critical role these machines play in the baking industry, ensuring that baked goods are packaged efficiently, safely, and attractively for consumers around the world.

| Report Metric | Details |

| Report Name | Baking Food Packaging Machine Market |

| Accounted market size in year | US$ 1850 million |

| Forecasted market size in 2031 | US$ 2628 million |

| CAGR | 5.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Production Capacity |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Syntegon, Schubert Group, nVenia, IMA, Middleby, ULMA Packaging, ProMach, Reiser, Paxiom, Minipack®-torre, Fuji Packaging GmbH, SR Pack, GHD Hartmann, Omori Machinery, SOMIC Packaging, Delkor Systems, PAC Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |