What is Global ACR Processing Aids Market?

The Global ACR Processing Aids Market refers to the worldwide industry focused on the production and distribution of acrylic processing aids (ACR). These aids are essential additives used in the manufacturing of polyvinyl chloride (PVC) products to enhance their processing characteristics. ACR processing aids improve the melt flow of PVC, making it easier to mold and shape into various products. This market is driven by the increasing demand for PVC products across various industries, including construction, automotive, and packaging. The versatility of PVC, combined with the efficiency provided by ACR processing aids, makes it a preferred material for many applications. As industries continue to seek materials that offer both performance and cost-effectiveness, the demand for ACR processing aids is expected to grow. This market is characterized by continuous innovation, with manufacturers striving to develop aids that offer better performance, environmental benefits, and cost savings. The global reach of this market indicates its significance in the broader context of industrial manufacturing and material science. The market's growth is also influenced by regulatory standards and the push for sustainable and environmentally friendly manufacturing processes.

Universal processing aids, Lubrication type processing aid, Efficient processing aids, Others in the Global ACR Processing Aids Market:

Universal processing aids are a category within the Global ACR Processing Aids Market that are designed to enhance the overall processing performance of PVC materials. These aids are versatile and can be used across a wide range of PVC applications, from pipes and fittings to profiles and sheets. They work by improving the melt flow and fusion characteristics of PVC, which in turn enhances the surface finish and mechanical properties of the final product. Universal processing aids are particularly valued for their ability to provide consistent performance across different processing conditions, making them a reliable choice for manufacturers looking to optimize their production processes. Lubrication type processing aids, on the other hand, are specifically formulated to reduce friction during the processing of PVC. This reduction in friction not only facilitates smoother processing but also helps in extending the life of processing equipment by minimizing wear and tear. These aids are crucial in applications where high-speed processing is required, as they help in maintaining the integrity of the equipment and the quality of the final product. Efficient processing aids are designed to maximize the processing efficiency of PVC by enhancing its melt strength and elasticity. These aids are particularly important in applications where the PVC needs to be stretched or expanded, as they help in maintaining the structural integrity of the material. Efficient processing aids are often used in the production of foamed PVC products, where they help in achieving the desired density and surface finish. Other types of processing aids in the Global ACR Processing Aids Market include those that are tailored for specific applications or performance requirements. These may include aids that enhance the UV stability of PVC products, making them suitable for outdoor applications, or those that improve the impact resistance of the material. The diversity of processing aids available in the market reflects the wide range of applications and performance requirements that PVC products need to meet. As the demand for PVC products continues to grow, the development of specialized processing aids is expected to play a crucial role in meeting the evolving needs of the industry.

PVC Pipe and Fitting, PVC Profiles and Window Frames, PVC Sheets and Boards, Others in the Global ACR Processing Aids Market:

The Global ACR Processing Aids Market plays a crucial role in the production of various PVC products, including PVC pipes and fittings, PVC profiles and window frames, PVC sheets and boards, and other applications. In the production of PVC pipes and fittings, ACR processing aids are essential for improving the melt flow and fusion characteristics of the PVC material. This results in pipes and fittings with enhanced mechanical properties, such as increased strength and durability, which are critical for applications in plumbing, irrigation, and drainage systems. The use of ACR processing aids also ensures a smooth surface finish, which is important for reducing friction and improving the flow of fluids through the pipes. In the case of PVC profiles and window frames, ACR processing aids help in achieving the desired shape and dimensions with precision. These aids enhance the melt strength and elasticity of the PVC, allowing it to be extruded into complex profiles without compromising on structural integrity. This is particularly important for window frames, where dimensional accuracy and surface finish are critical for ensuring a proper fit and aesthetic appeal. ACR processing aids also contribute to the UV stability of PVC profiles, making them suitable for outdoor applications where exposure to sunlight is a concern. For PVC sheets and boards, ACR processing aids are used to improve the processing efficiency and surface quality of the material. These aids help in achieving a uniform thickness and smooth surface finish, which are important for applications in construction, signage, and furniture. The enhanced melt strength provided by ACR processing aids also allows for the production of foamed PVC sheets and boards, which are lightweight and offer excellent insulation properties. In addition to these specific applications, ACR processing aids are used in a variety of other PVC products, including cables, films, and packaging materials. The versatility of ACR processing aids makes them an indispensable component in the production of PVC products, enabling manufacturers to meet the diverse needs of different industries. As the demand for PVC products continues to grow, the role of ACR processing aids in enhancing the performance and quality of these products is expected to become increasingly important.

Global ACR Processing Aids Market Outlook:

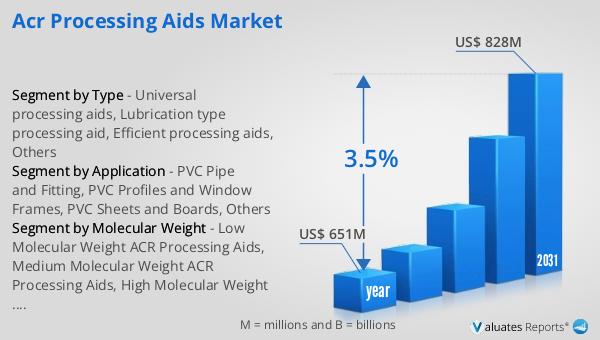

The global market for ACR Processing Aids was valued at $651 million in 2024, and it is anticipated to expand to a revised size of $828 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.5% over the forecast period. This growth trajectory underscores the increasing demand for ACR processing aids across various industries, driven by the need for enhanced processing efficiency and product quality in PVC manufacturing. The steady growth rate indicates a stable market environment, where manufacturers are continuously seeking ways to optimize their production processes and improve the performance of their PVC products. The projected market size by 2031 highlights the significant role that ACR processing aids play in the broader context of industrial manufacturing and material science. As industries continue to evolve and seek materials that offer both performance and cost-effectiveness, the demand for ACR processing aids is expected to remain strong. This market outlook reflects the ongoing innovation and development within the industry, as manufacturers strive to create processing aids that offer better performance, environmental benefits, and cost savings. The global reach of this market indicates its significance in the broader context of industrial manufacturing and material science, with a focus on sustainable and environmentally friendly manufacturing processes.

| Report Metric | Details |

| Report Name | ACR Processing Aids Market |

| Accounted market size in year | US$ 651 million |

| Forecasted market size in 2031 | US$ 828 million |

| CAGR | 3.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Physical Form |

|

| Segment by Molecular Weight |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Dow, Kaneka, Arkema, Formosa Plastic Group, Mitsubishi Chemical, LG Chem, RUIFENG CHEM, Akdeniz Chemson, Shandong Donglin New Materials, Shadong Hongfu Chemicals, Wuxi Jubang Auxiliaries, Yuanbang New Material, Bontecn Group China, Shine Polymer, Shandong Novista Chemicals, Shandong Jinchangshu New Material |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |