What is Pharmaceutical Fluid Bed Dryer - Global Market?

Pharmaceutical Fluid Bed Dryers are essential equipment in the global pharmaceutical market, playing a crucial role in the production of various medicinal products. These dryers are used to dry, granulate, and coat particles, which are vital processes in the manufacturing of tablets and capsules. The fluid bed drying technology involves suspending solid particles in a hot air stream, allowing for efficient and uniform drying. This method is preferred due to its ability to handle heat-sensitive materials, ensuring that the active pharmaceutical ingredients (APIs) retain their efficacy. The global market for pharmaceutical fluid bed dryers is driven by the increasing demand for advanced drug formulations and the need for efficient manufacturing processes. As pharmaceutical companies strive to meet stringent regulatory standards and enhance production efficiency, the adoption of fluid bed dryers is expected to rise. This market is characterized by technological advancements, with manufacturers focusing on developing energy-efficient and environmentally friendly solutions. The growing emphasis on personalized medicine and the expansion of the pharmaceutical industry in emerging markets further contribute to the demand for fluid bed dryers. Overall, the pharmaceutical fluid bed dryer market is poised for significant growth, driven by the continuous evolution of drug manufacturing technologies and the increasing focus on quality and efficiency in pharmaceutical production.

Below 100 L, 100-500 L, 500-1000 L, Above 1000 L in the Pharmaceutical Fluid Bed Dryer - Global Market:

In the global market for pharmaceutical fluid bed dryers, the equipment is categorized based on their capacity, which ranges from below 100 liters to above 1000 liters. Each category serves different scales of production and is chosen based on the specific needs of pharmaceutical manufacturers. Fluid bed dryers with a capacity below 100 liters are typically used in research and development settings or for small-scale production. These units are ideal for laboratories and pilot plants where new formulations are tested and developed. They offer flexibility and precision, allowing researchers to experiment with different drying parameters and optimize the process for specific drug formulations. The 100-500 liter category is suitable for medium-scale production, often used by pharmaceutical companies that produce a moderate volume of drugs. These dryers provide a balance between capacity and efficiency, making them a popular choice for companies looking to scale up their production without investing in large-scale equipment. The 500-1000 liter fluid bed dryers cater to larger production needs, often used by manufacturers with a diverse product portfolio. These units are designed to handle higher volumes of material, ensuring consistent quality and efficiency in the drying process. They are equipped with advanced features such as automated controls and monitoring systems, which enhance operational efficiency and reduce the risk of errors. Finally, fluid bed dryers with a capacity above 1000 liters are used in large-scale pharmaceutical manufacturing facilities. These units are capable of processing significant quantities of material, making them ideal for companies with high production demands. They are often integrated into fully automated production lines, ensuring seamless operation and minimal downtime. The choice of fluid bed dryer capacity depends on various factors, including the scale of production, the type of drug being manufactured, and the specific requirements of the manufacturing process. As the pharmaceutical industry continues to evolve, manufacturers are increasingly investing in advanced fluid bed dryers that offer greater flexibility, efficiency, and control. This trend is driven by the need to meet regulatory standards, reduce production costs, and enhance the quality of pharmaceutical products. Overall, the global market for pharmaceutical fluid bed dryers is diverse, with a wide range of options available to meet the varying needs of manufacturers. Whether for small-scale research or large-scale production, fluid bed dryers play a critical role in ensuring the efficiency and quality of pharmaceutical manufacturing processes.

Medicine, Health Products, Others in the Pharmaceutical Fluid Bed Dryer - Global Market:

Pharmaceutical fluid bed dryers are widely used in the production of medicines, health products, and other related applications. In the field of medicine, these dryers are essential for the production of tablets and capsules, which are the most common forms of drug delivery. The fluid bed drying process ensures that the active pharmaceutical ingredients (APIs) are evenly distributed and properly dried, which is crucial for maintaining the efficacy and stability of the final product. This technology is particularly beneficial for heat-sensitive drugs, as it allows for gentle drying without compromising the integrity of the APIs. In addition to medicines, fluid bed dryers are also used in the production of health products such as vitamins, supplements, and nutraceuticals. These products often contain a combination of active ingredients and excipients, which need to be uniformly mixed and dried to ensure consistent quality and performance. Fluid bed dryers provide an efficient and reliable solution for achieving this, allowing manufacturers to produce high-quality health products that meet consumer expectations. Beyond medicines and health products, fluid bed dryers are also used in other applications within the pharmaceutical industry. For example, they are employed in the production of excipients, which are inactive substances used as carriers for the active ingredients in drugs. The drying and granulation capabilities of fluid bed dryers make them ideal for producing excipients with the desired properties, such as flowability and compressibility. Additionally, fluid bed dryers are used in the coating of particles, which is a critical process in the production of controlled-release formulations. By applying a uniform coating to the particles, manufacturers can control the release rate of the active ingredients, enhancing the therapeutic efficacy of the drug. Overall, the versatility and efficiency of pharmaceutical fluid bed dryers make them indispensable tools in the production of a wide range of pharmaceutical products. As the demand for innovative drug formulations and health products continues to grow, the use of fluid bed dryers is expected to increase, driving advancements in pharmaceutical manufacturing processes.

Pharmaceutical Fluid Bed Dryer - Global Market Outlook:

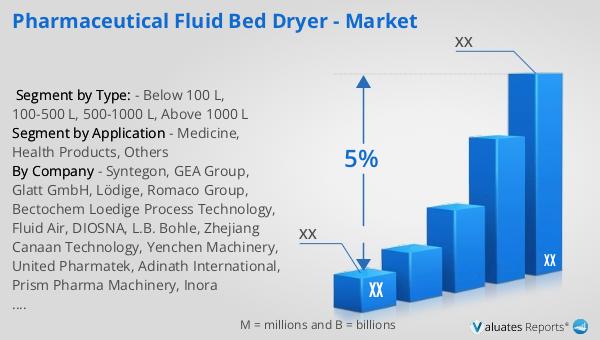

The global pharmaceutical market was valued at approximately 1475 billion USD in 2022, and it is projected to grow at a compound annual growth rate (CAGR) of 5% over the next six years. This growth is indicative of the increasing demand for pharmaceutical products worldwide, driven by factors such as an aging population, rising prevalence of chronic diseases, and advancements in drug development. In comparison, the chemical drug market has also shown significant growth, with its value increasing from 1005 billion USD in 2018 to 1094 billion USD in 2022. This growth reflects the ongoing demand for chemical drugs, which continue to play a vital role in the treatment of various medical conditions. The pharmaceutical market's expansion is supported by continuous research and development efforts, leading to the introduction of new and innovative drug formulations. Additionally, the increasing focus on personalized medicine and the development of biologics are contributing to the market's growth. As pharmaceutical companies strive to meet the evolving needs of patients and healthcare providers, the market is expected to witness further advancements and opportunities. The growth of the pharmaceutical market also highlights the importance of efficient manufacturing processes and technologies, such as pharmaceutical fluid bed dryers, which play a crucial role in ensuring the quality and efficacy of drug products. Overall, the global pharmaceutical market is poised for continued growth, driven by the increasing demand for effective and innovative healthcare solutions.

| Report Metric | Details |

| Report Name | Pharmaceutical Fluid Bed Dryer - Market |

| CAGR | 5% |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Syntegon, GEA Group, Glatt GmbH, Lödige, Romaco Group, Bectochem Loedige Process Technology, Fluid Air, DIOSNA, L.B. Bohle, Zhejiang Canaan Technology, Yenchen Machinery, United Pharmatek, Adinath International, Prism Pharma Machinery, Inora Pharmaceutical Machinery, Cos.Mec, O'Hara Technologies, Freund-Vector, Riddhi Pharma Machinery, Xianfeng Drying Engineering, Senieer |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |