What is Global 1D Laser Triangulation Displacement Sensors Market?

The Global 1D Laser Triangulation Displacement Sensors Market is a specialized segment within the broader field of sensor technology, focusing on devices that utilize laser triangulation to measure displacement. These sensors are designed to provide precise measurements of distance, position, and displacement by emitting a laser beam onto a target surface and analyzing the reflected light. The technology is based on the principle of triangulation, where the angle of the reflected laser beam is used to calculate the distance to the target. This market is driven by the increasing demand for high-precision measurement tools across various industries, including automotive, aerospace, manufacturing, and electronics. The sensors are valued for their ability to deliver accurate and reliable data, which is crucial for quality control, automation, and process optimization. As industries continue to advance towards automation and precision engineering, the demand for 1D laser triangulation displacement sensors is expected to grow, offering opportunities for innovation and development in sensor technology. The market is characterized by a range of products that vary in terms of measurement range, accuracy, and application suitability, catering to diverse industrial needs.

≤ 2µm, 3~10µm, 11~50µm, 51~100µm, 101~500µm, Others in the Global 1D Laser Triangulation Displacement Sensors Market:

In the Global 1D Laser Triangulation Displacement Sensors Market, the sensors are categorized based on their measurement accuracy, which is crucial for different applications. The ≤ 2µm category represents sensors with the highest precision, suitable for applications requiring extremely fine measurements, such as semiconductor manufacturing and high-precision machining. These sensors are essential in environments where even the slightest deviation can lead to significant quality issues. The 3~10µm range sensors offer a balance between precision and cost, making them ideal for applications in the automotive and aerospace industries where precision is important but not as critical as in semiconductor manufacturing. These sensors are often used in quality control processes to ensure components meet specified tolerances. The 11~50µm sensors are typically used in industrial manufacturing processes where moderate precision is sufficient. They are commonly employed in assembly lines and production environments to monitor and control the positioning of parts and components. The 51~100µm sensors are suitable for applications where precision is less critical, such as in logistics and material handling. These sensors are used to measure the displacement of larger objects or to monitor the position of items on conveyor belts. The 101~500µm sensors are used in applications where rough measurements are acceptable, such as in construction and heavy machinery. These sensors are often used to monitor the position of large structures or to measure the displacement of heavy equipment. The "Others" category includes sensors that do not fit neatly into the specified ranges, offering unique features or capabilities for specialized applications. This diversity in measurement accuracy allows the Global 1D Laser Triangulation Displacement Sensors Market to cater to a wide range of industries and applications, providing solutions that meet specific measurement needs.

Automotive Industry, Aerospace & Military Industry, Industrial Manufacturing, Electronics and Photovoltaic Industry, Logistics, Others in the Global 1D Laser Triangulation Displacement Sensors Market:

The Global 1D Laser Triangulation Displacement Sensors Market finds extensive usage across various industries due to its ability to provide precise and reliable measurements. In the automotive industry, these sensors are used for quality control and inspection processes, ensuring that components meet strict tolerances and specifications. They are also employed in automated assembly lines to monitor the position and alignment of parts, contributing to the efficiency and accuracy of manufacturing processes. In the aerospace and military industry, the sensors are used for precision measurement and alignment of components, which is critical for the safety and performance of aircraft and military equipment. They are also used in testing and inspection processes to ensure that parts meet stringent quality standards. In industrial manufacturing, the sensors are used to monitor and control production processes, ensuring that products are manufactured to the required specifications. They are also used in automation systems to provide feedback on the position and movement of machinery and equipment. In the electronics and photovoltaic industry, the sensors are used for the precise measurement and alignment of components, which is essential for the production of high-quality electronic devices and solar panels. They are also used in quality control processes to ensure that products meet the required standards. In logistics, the sensors are used to monitor the position and movement of goods, ensuring efficient and accurate handling and transportation. They are also used in automated sorting and packaging systems to ensure that items are correctly positioned and aligned. The "Others" category includes applications in industries such as construction, healthcare, and agriculture, where the sensors are used for a variety of measurement and monitoring tasks. The versatility and precision of 1D laser triangulation displacement sensors make them an invaluable tool in a wide range of industries, contributing to improved quality, efficiency, and productivity.

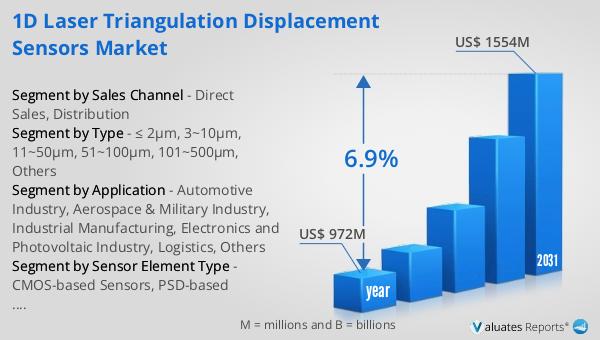

Global 1D Laser Triangulation Displacement Sensors Market Outlook:

The global market for 1D Laser Triangulation Displacement Sensors was valued at approximately $972 million in 2024. This market is anticipated to expand significantly, reaching an estimated size of $1,554 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.9% over the forecast period. This upward trend is indicative of the increasing demand for precision measurement tools across various industries. As industries continue to evolve and place greater emphasis on automation and precision, the need for advanced sensor technologies like 1D laser triangulation displacement sensors is expected to rise. These sensors are crucial for ensuring quality control, optimizing processes, and enhancing productivity in sectors such as automotive, aerospace, manufacturing, and electronics. The projected growth of this market underscores the importance of innovation and development in sensor technology to meet the diverse needs of these industries. As the market expands, it presents opportunities for companies to develop new products and solutions that cater to the specific requirements of different applications, driving further advancements in the field of sensor technology.

| Report Metric | Details |

| Report Name | 1D Laser Triangulation Displacement Sensors Market |

| Accounted market size in year | US$ 972 million |

| Forecasted market size in 2031 | US$ 1554 million |

| CAGR | 6.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Sensor Element Type |

|

| Segment by Sales Channel |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | KEYENCE, SICK, Panasonic, OMRON, COGNEX, OPTEX FA CO.,LTD., Turck, Banner Engineering, Micro-Epsilon, Baumer, Leuze, SENSOPART, ELAG, Pepperl&Fuchs, Balluff, Sunny Optical, Acuity, MTI Instruments |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |