What is Global Food Packaging Anti-Fog Additive Market?

The Global Food Packaging Anti-Fog Additive Market is a specialized segment within the broader packaging industry, focusing on additives that prevent fog formation on food packaging materials. Fogging occurs when moisture condenses on the inside of packaging films, creating a cloudy appearance that can obscure the visibility of the product inside. This is particularly problematic for fresh produce, meats, and other perishable items where visual appeal is crucial for consumer decision-making. Anti-fog additives are incorporated into packaging materials to maintain clarity, thereby enhancing the aesthetic appeal and perceived freshness of the packaged food. These additives work by reducing the surface tension of water droplets, causing them to spread into a thin, transparent layer rather than forming opaque droplets. The demand for such additives is driven by the growing consumer preference for fresh and visually appealing food products, as well as the increasing use of transparent packaging in the food industry. As global food supply chains become more complex and consumer expectations rise, the role of anti-fog additives in ensuring product quality and shelf appeal becomes increasingly important. This market is characterized by continuous innovation, as manufacturers strive to develop more effective and environmentally friendly solutions to meet the evolving needs of the food packaging industry.

Bio-based Anti-Fog Additive, Non-bio-based Anti-Fog Additive in the Global Food Packaging Anti-Fog Additive Market:

Bio-based Anti-Fog Additives are derived from natural sources and are gaining traction in the Global Food Packaging Anti-Fog Additive Market due to their environmentally friendly properties. These additives are typically made from renewable resources such as plant oils, starches, and other organic materials. The primary advantage of bio-based additives is their reduced environmental impact, as they are biodegradable and contribute to the reduction of plastic waste. In addition, they align with the growing consumer demand for sustainable and eco-friendly packaging solutions. Bio-based anti-fog additives work by modifying the surface properties of the packaging film, preventing the formation of water droplets that cause fogging. They are particularly effective in maintaining the clarity of packaging for fresh produce, meats, and dairy products, where visibility is crucial for consumer appeal. On the other hand, Non-bio-based Anti-Fog Additives are typically derived from synthetic materials and have been the traditional choice in the market. These additives are often more cost-effective and can offer superior performance in terms of durability and effectiveness. Non-bio-based additives work by altering the surface energy of the packaging film, ensuring that moisture spreads evenly across the surface rather than forming droplets. While they are highly effective, there is growing concern about their environmental impact, as they are not biodegradable and can contribute to plastic pollution. Despite these concerns, non-bio-based additives remain popular due to their proven track record and cost advantages. The choice between bio-based and non-bio-based anti-fog additives often depends on the specific requirements of the packaging application, including factors such as cost, performance, and environmental considerations. As the market evolves, there is a growing trend towards the development of hybrid solutions that combine the benefits of both bio-based and non-bio-based additives. These hybrid solutions aim to offer the best of both worlds, providing effective anti-fog performance while minimizing environmental impact. The ongoing research and development in this area are expected to drive innovation and expand the range of options available to manufacturers and consumers alike. As sustainability becomes an increasingly important consideration in the packaging industry, the demand for bio-based anti-fog additives is expected to grow, although non-bio-based additives will likely continue to play a significant role due to their established presence and cost-effectiveness. Ultimately, the choice of anti-fog additive will depend on a variety of factors, including the specific needs of the product being packaged, the target market, and the environmental goals of the manufacturer.

Vegetables, Fruits, Others in the Global Food Packaging Anti-Fog Additive Market:

The usage of Global Food Packaging Anti-Fog Additives is particularly significant in the packaging of vegetables, fruits, and other perishable items. For vegetables, maintaining freshness and visual appeal is crucial, as consumers often associate the appearance of produce with its quality and taste. Anti-fog additives help ensure that the packaging remains clear, allowing consumers to easily assess the freshness of the vegetables inside. This is especially important in retail environments where the visual appeal of the product can directly influence purchasing decisions. By preventing fogging, these additives help extend the shelf life of vegetables by reducing the accumulation of moisture, which can lead to spoilage. Similarly, in the packaging of fruits, anti-fog additives play a vital role in preserving the aesthetic appeal and perceived freshness of the product. Fruits are often sold in transparent packaging to showcase their natural colors and textures, and any fogging can detract from their visual appeal. Anti-fog additives help maintain the clarity of the packaging, ensuring that consumers can clearly see the product they are purchasing. This is particularly important for premium fruits, where appearance is a key selling point. In addition to vegetables and fruits, anti-fog additives are also used in the packaging of other perishable items such as meats, dairy products, and ready-to-eat meals. In these applications, the primary goal is to maintain product visibility and freshness, as well as to prevent the growth of bacteria and mold that can occur in moist environments. By reducing fogging, these additives help create a more hygienic packaging environment, which can enhance food safety and quality. The use of anti-fog additives in these areas is driven by the increasing consumer demand for fresh, high-quality food products, as well as the growing trend towards convenience and ready-to-eat meals. As the global food industry continues to evolve, the importance of anti-fog additives in ensuring product quality and consumer satisfaction is expected to grow. Manufacturers are continually seeking new and innovative solutions to meet the changing needs of the market, and the development of more effective and sustainable anti-fog additives is a key focus area. Overall, the use of anti-fog additives in the packaging of vegetables, fruits, and other perishable items is essential for maintaining product quality, extending shelf life, and enhancing consumer appeal.

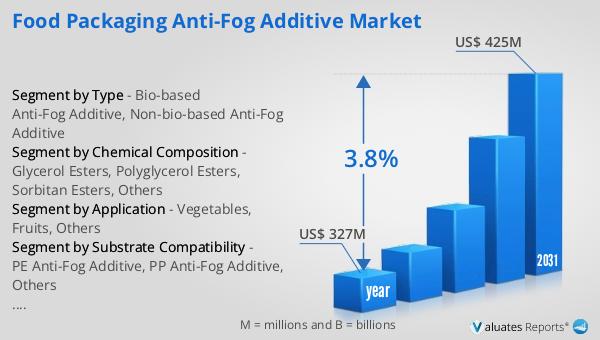

Global Food Packaging Anti-Fog Additive Market Outlook:

In 2024, the global market for Food Packaging Anti-Fog Additives was valued at approximately $327 million. This market is anticipated to expand, reaching an estimated size of $425 million by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 3.8% over the forecast period. The steady increase in market size underscores the rising demand for anti-fog additives in food packaging, driven by consumer preferences for clear, visually appealing packaging that enhances the perceived freshness and quality of food products. As the food packaging industry continues to innovate and adapt to changing consumer expectations, the role of anti-fog additives becomes increasingly significant. These additives not only improve the aesthetic appeal of packaged foods but also contribute to extending shelf life and maintaining product quality. The projected growth in the market is indicative of the broader trends towards transparency and sustainability in packaging, as well as the ongoing efforts by manufacturers to develop more effective and environmentally friendly solutions. As the market evolves, the demand for both bio-based and non-bio-based anti-fog additives is expected to grow, with manufacturers seeking to balance performance, cost, and environmental impact. The continued focus on research and development in this area is likely to drive further innovation and expand the range of options available to the food packaging industry. Overall, the growth of the Global Food Packaging Anti-Fog Additive Market reflects the increasing importance of these additives in meeting the needs of consumers and manufacturers alike.

| Report Metric | Details |

| Report Name | Food Packaging Anti-Fog Additive Market |

| Accounted market size in year | US$ 327 million |

| Forecasted market size in 2031 | US$ 425 million |

| CAGR | 3.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Chemical Composition |

|

| Segment by Substrate Compatibility |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Cargill, Avient, SABO SpA, Evonik, Van Meeuwen, NICHEM Solutions, Primex Plastics Corporation, Ampacet Corporation, Palsgaard, Tosaf, Kompuestos, EuroPlas, Techmer PM, Kandui |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |