What is Global OES Endpoint Detection System Market?

The Global OES (Optical Emission Spectroscopy) Endpoint Detection System Market is a specialized segment within the broader field of semiconductor manufacturing and process control. This market focuses on the development and deployment of systems that utilize optical emission spectroscopy to monitor and control the endpoint of various semiconductor fabrication processes. These systems are crucial in ensuring precision and efficiency in the manufacturing of semiconductor devices. By analyzing the light emitted from plasma during processes like etching and deposition, OES endpoint detection systems can determine the exact moment a process should be stopped to achieve the desired material characteristics. This precision is vital for maintaining the quality and performance of semiconductor components, which are foundational to modern electronics. The market for these systems is driven by the increasing demand for high-performance semiconductor devices, advancements in semiconductor manufacturing technologies, and the need for more efficient and accurate process control solutions. As the semiconductor industry continues to evolve, the role of OES endpoint detection systems becomes increasingly important, making this market a critical area of focus for technology developers and manufacturers alike.

Intensity-Based, Ratio-Based in the Global OES Endpoint Detection System Market:

In the realm of the Global OES Endpoint Detection System Market, two primary methodologies are employed: Intensity-Based and Ratio-Based detection. Intensity-Based detection relies on monitoring the intensity of specific wavelengths of light emitted during a semiconductor process. This method is straightforward and involves measuring the absolute intensity of the light emitted by the plasma. The intensity of certain wavelengths correlates with the concentration of specific elements or compounds in the plasma, allowing for the detection of process endpoints. This approach is particularly useful in processes where the concentration of a particular element changes significantly at the endpoint, providing a clear signal for process termination. However, Intensity-Based detection can be susceptible to variations in plasma conditions, such as changes in pressure or power, which can affect the intensity readings and potentially lead to inaccuracies. On the other hand, Ratio-Based detection offers a more robust solution by comparing the intensity of two or more wavelengths. This method involves calculating the ratio of the intensities of different wavelengths, which can provide a more stable and reliable endpoint detection signal. By using ratios, this approach compensates for variations in plasma conditions that might affect the absolute intensity of individual wavelengths. Ratio-Based detection is particularly advantageous in complex processes where multiple elements are present, and the endpoint is characterized by a change in the relative concentrations of these elements. This method can provide a clearer and more consistent signal for process control, reducing the likelihood of errors and improving the overall efficiency of semiconductor manufacturing. Both Intensity-Based and Ratio-Based detection methods have their own advantages and limitations, and the choice between them depends on the specific requirements of the semiconductor process being monitored. Intensity-Based detection is simpler and can be more cost-effective, making it suitable for processes with well-defined and significant changes in element concentration at the endpoint. However, for more complex processes or those with less pronounced changes, Ratio-Based detection offers greater accuracy and reliability. As semiconductor manufacturing continues to advance, the demand for more precise and efficient endpoint detection systems is likely to grow, driving further innovation and development in both Intensity-Based and Ratio-Based methodologies. The ongoing evolution of these technologies will play a crucial role in enhancing the performance and quality of semiconductor devices, supporting the continued growth and advancement of the electronics industry.

Etching, Thin Film Deposition, Other in the Global OES Endpoint Detection System Market:

The Global OES Endpoint Detection System Market finds significant applications in various areas of semiconductor manufacturing, including etching, thin film deposition, and other related processes. In the etching process, OES endpoint detection systems are used to precisely monitor the removal of material from the surface of a semiconductor wafer. Etching is a critical step in defining the intricate patterns and structures on a semiconductor device, and accurate endpoint detection is essential to ensure that the desired features are achieved without over-etching or under-etching. By analyzing the optical emissions from the plasma used in the etching process, OES systems can determine the exact moment when the etching should be stopped, ensuring high precision and consistency in the manufacturing process. In thin film deposition, OES endpoint detection systems play a crucial role in monitoring the growth of thin films on semiconductor wafers. Thin film deposition is used to create the various layers that make up a semiconductor device, and precise control over the thickness and composition of these layers is essential for device performance. OES systems provide real-time feedback on the deposition process by analyzing the light emitted from the plasma, allowing manufacturers to adjust process parameters and achieve the desired film characteristics. This capability is particularly important in advanced semiconductor devices, where even slight variations in film thickness or composition can significantly impact performance. Beyond etching and thin film deposition, OES endpoint detection systems are also used in other semiconductor manufacturing processes, such as chemical vapor deposition (CVD) and physical vapor deposition (PVD). In these processes, OES systems help ensure that the deposition of materials is carried out with high precision and accuracy, contributing to the overall quality and reliability of the final semiconductor products. The versatility and effectiveness of OES endpoint detection systems make them an indispensable tool in the semiconductor industry, supporting the production of high-performance devices that power modern electronics. As the demand for more advanced and efficient semiconductor devices continues to grow, the role of OES endpoint detection systems in ensuring process control and quality assurance will become increasingly important, driving further innovation and development in this critical area of technology.

Global OES Endpoint Detection System Market Outlook:

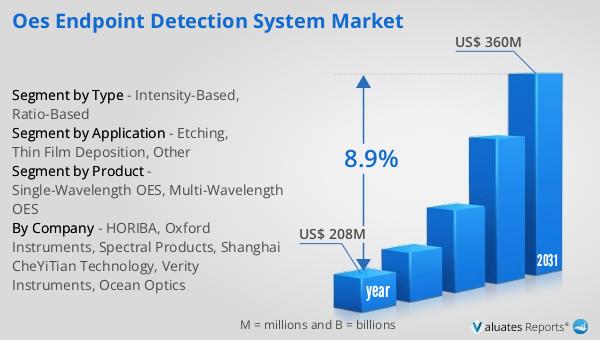

The global market for OES Endpoint Detection Systems was valued at approximately $208 million in 2024. This market is anticipated to experience significant growth, reaching an estimated size of $360 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 8.9% over the forecast period. The increasing demand for high-performance semiconductor devices, coupled with advancements in semiconductor manufacturing technologies, is driving the expansion of this market. As semiconductor devices become more complex and require greater precision in their manufacturing processes, the need for accurate and efficient endpoint detection systems becomes more critical. OES endpoint detection systems, with their ability to provide real-time feedback and precise control over semiconductor processes, are well-positioned to meet this demand. The projected growth of the OES Endpoint Detection System Market reflects the broader trends in the semiconductor industry, where innovation and technological advancement are key drivers of market expansion. As the market continues to evolve, manufacturers and technology developers will need to focus on enhancing the capabilities and performance of OES endpoint detection systems to meet the growing demands of the semiconductor industry.

| Report Metric | Details |

| Report Name | OES Endpoint Detection System Market |

| Accounted market size in year | US$ 208 million |

| Forecasted market size in 2031 | US$ 360 million |

| CAGR | 8.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Product |

|

| Segment by Application |

|

| By Region |

|

| By Company | HORIBA, Oxford Instruments, Spectral Products, Shanghai CheYiTian Technology, Verity Instruments, Ocean Optics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |