What is Global Inert Gas Convection Oven Market?

The Global Inert Gas Convection Oven Market is a specialized segment within the broader industrial oven market, focusing on ovens that utilize inert gases to create a controlled atmosphere for various applications. These ovens are designed to prevent oxidation and other chemical reactions that can occur when materials are exposed to air at high temperatures. By using inert gases such as nitrogen, argon, or helium, these ovens provide a stable environment that is essential for processes requiring precise temperature control and minimal contamination. Industries such as electronics, aerospace, and scientific research rely heavily on these ovens for tasks like curing, drying, and heat treatment. The market for inert gas convection ovens is driven by the increasing demand for high-quality manufacturing processes and the need for advanced materials that can withstand extreme conditions. As technology continues to evolve, the applications for these ovens are expanding, making them an integral part of modern industrial processes. The market is characterized by a diverse range of products, each tailored to specific industry needs, and is supported by ongoing research and development efforts aimed at enhancing performance and efficiency.

Nitrogen, Argon, Helium, Other in the Global Inert Gas Convection Oven Market:

In the Global Inert Gas Convection Oven Market, different inert gases are employed based on their unique properties and suitability for specific applications. Nitrogen is the most commonly used inert gas due to its abundance and cost-effectiveness. It is ideal for processes that require a non-reactive atmosphere to prevent oxidation, such as in the electronics and semiconductor industries. Nitrogen's inert nature makes it perfect for creating a stable environment for heat treatment and soldering processes, ensuring the integrity of sensitive components. Argon, another popular choice, is often used in applications where a higher level of inertness is required. Its heavier nature compared to nitrogen makes it suitable for processes that involve denser materials or require a more robust protective atmosphere. Argon is frequently used in the aerospace industry for welding and other high-temperature applications where precision and quality are paramount. Helium, although more expensive, is chosen for its excellent thermal conductivity and low density. It is particularly useful in scientific research and experimentation, where precise temperature control and rapid heat transfer are crucial. Helium's unique properties make it ideal for applications involving delicate materials or where rapid cooling is necessary. Other inert gases, such as neon or krypton, are used less frequently but can be found in niche applications where their specific characteristics offer advantages. The choice of inert gas in convection ovens is determined by factors such as cost, availability, and the specific requirements of the process being undertaken. Each gas offers distinct benefits, and the selection often involves a trade-off between performance and expense. As industries continue to innovate and demand more sophisticated manufacturing techniques, the role of inert gases in convection ovens becomes increasingly important. The ability to tailor the atmosphere within these ovens to meet precise specifications is a key factor driving their adoption across various sectors. Manufacturers are continually exploring new ways to optimize the use of inert gases, seeking to enhance efficiency, reduce costs, and improve the quality of the end products. This ongoing development is a testament to the critical role that inert gas convection ovens play in modern industrial processes, providing the controlled environments necessary for cutting-edge applications.

Aerospace, Scientific Research and Experimentation, Electronics and Semiconductors, Other in the Global Inert Gas Convection Oven Market:

The Global Inert Gas Convection Oven Market finds extensive usage across several key areas, each benefiting from the unique capabilities of these specialized ovens. In the aerospace industry, inert gas convection ovens are crucial for processes such as heat treatment and welding of high-performance materials. The controlled atmosphere provided by inert gases like argon ensures that components are free from oxidation and other contaminants, which is vital for maintaining the structural integrity and performance of aerospace parts. These ovens enable the precise temperature control required for manufacturing advanced materials used in aircraft and spacecraft, contributing to the overall safety and efficiency of aerospace operations. In the realm of scientific research and experimentation, inert gas convection ovens are indispensable tools for conducting experiments that require a stable and contamination-free environment. Researchers rely on these ovens to perform delicate procedures, such as the synthesis of new materials or the study of chemical reactions under controlled conditions. The use of inert gases like helium allows for rapid heat transfer and precise temperature regulation, which are essential for obtaining accurate and reproducible results. In the electronics and semiconductor industries, inert gas convection ovens play a pivotal role in processes such as soldering, annealing, and curing. The non-reactive atmosphere provided by gases like nitrogen prevents oxidation and ensures the reliability and longevity of electronic components. These ovens are integral to the production of high-quality semiconductors and electronic devices, where even minor impurities can lead to significant performance issues. Other industries also benefit from the capabilities of inert gas convection ovens, including the automotive, medical, and energy sectors. In each of these areas, the ability to create a controlled atmosphere is critical for processes that demand high precision and quality. The versatility and adaptability of inert gas convection ovens make them valuable assets in a wide range of applications, supporting the advancement of technology and innovation across multiple fields.

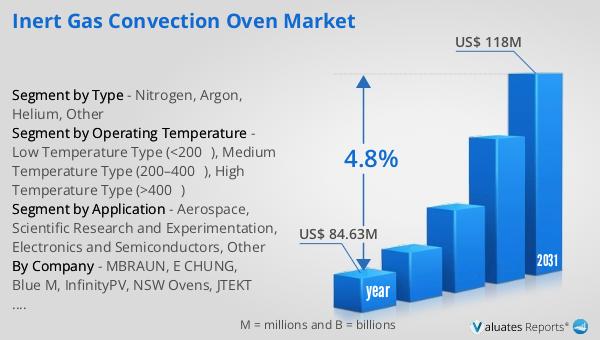

Global Inert Gas Convection Oven Market Outlook:

The global market for Inert Gas Convection Ovens was valued at approximately $84.63 million in 2024, and it is anticipated to grow significantly, reaching an estimated value of $118 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.8% over the forecast period. The increasing demand for these ovens is driven by their critical role in various industries, including aerospace, electronics, and scientific research, where precise temperature control and contamination-free environments are essential. As industries continue to evolve and require more sophisticated manufacturing processes, the need for inert gas convection ovens is likely to rise. These ovens offer the ability to create stable atmospheres using inert gases, which is crucial for processes that involve sensitive materials or require high precision. The market's expansion is also supported by ongoing advancements in technology, which are enhancing the performance and efficiency of these ovens. Manufacturers are continually innovating to meet the growing demands of their customers, focusing on improving the quality and reliability of their products. As a result, the global inert gas convection oven market is poised for steady growth, driven by the increasing adoption of these ovens across various sectors and the continuous development of new applications.

| Report Metric | Details |

| Report Name | Inert Gas Convection Oven Market |

| Accounted market size in year | US$ 84.63 million |

| Forecasted market size in 2031 | US$ 118 million |

| CAGR | 4.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Operating Temperature |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | MBRAUN, E CHUNG, Blue M, InfinityPV, NSW Ovens, JTEKT Thermo Systems, GMS Industrial, Better Technology Group Limited, Yamato Scientific America Inc., Lien Ming Machinery Corporation, Battery Technology Source Co. Ltd.(BTS), Grieve |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |