What is Global Automotive Thermal Runaway Insulation Materials Market?

The Global Automotive Thermal Runaway Insulation Materials Market is a specialized segment within the broader automotive industry, focusing on materials designed to manage and mitigate the risks associated with thermal runaway events in electric vehicles (EVs). Thermal runaway is a critical safety concern, particularly in lithium-ion batteries, where an increase in temperature can lead to a self-sustaining reaction, potentially causing fires or explosions. This market encompasses a range of materials engineered to provide thermal insulation, thereby enhancing the safety and reliability of EVs. These materials are crucial for maintaining optimal battery temperatures, preventing overheating, and ensuring the longevity and performance of the vehicle. As the automotive industry increasingly shifts towards electrification, the demand for effective thermal management solutions is on the rise. This market is driven by the growing adoption of electric vehicles, stringent safety regulations, and the need for advanced materials that can withstand high temperatures while providing efficient insulation. Manufacturers and suppliers in this market are continually innovating to develop materials that offer superior thermal resistance, lightweight properties, and cost-effectiveness, thereby supporting the global transition to sustainable transportation solutions.

Inorganic Thermal Insulation Materials, Organic Thermal Insulation Materials in the Global Automotive Thermal Runaway Insulation Materials Market:

In the realm of Global Automotive Thermal Runaway Insulation Materials, two primary categories of materials are utilized: inorganic and organic thermal insulation materials. Inorganic thermal insulation materials are typically composed of minerals and other non-organic substances. These materials are renowned for their high thermal resistance, durability, and non-combustibility, making them ideal for applications where safety and longevity are paramount. Common inorganic materials include fiberglass, mineral wool, and ceramic fibers. Fiberglass, for instance, is widely used due to its excellent thermal insulation properties and resistance to high temperatures. It is lightweight, easy to install, and provides effective insulation against heat transfer. Mineral wool, another popular choice, is made from natural or synthetic minerals and offers superior fire resistance and soundproofing capabilities. Ceramic fibers, on the other hand, are known for their exceptional heat resistance and are often used in high-temperature applications. These inorganic materials are crucial in the automotive industry, particularly in electric vehicles, where managing heat generated by batteries is essential for safety and performance. On the other hand, organic thermal insulation materials are derived from carbon-based compounds and are often used for their lightweight and flexible properties. These materials include polyurethane foam, polystyrene, and cellulose. Polyurethane foam is a versatile material that provides excellent thermal insulation and is commonly used in various automotive applications. It is lightweight, easy to mold, and offers good resistance to moisture and chemicals. Polystyrene, available in both expanded (EPS) and extruded (XPS) forms, is another popular organic insulation material. It is known for its high compressive strength, moisture resistance, and thermal insulation properties. Cellulose, made from recycled paper products, is an eco-friendly option that offers good thermal performance and soundproofing capabilities. While organic materials may not offer the same level of fire resistance as inorganic materials, they are often preferred for applications where weight and flexibility are critical considerations. In the context of the Global Automotive Thermal Runaway Insulation Materials Market, both inorganic and organic materials play a vital role in ensuring the safety and efficiency of electric vehicles. As the demand for EVs continues to grow, manufacturers are increasingly focusing on developing advanced insulation materials that can effectively manage thermal runaway risks while meeting the industry's stringent safety standards. This involves a delicate balance between achieving optimal thermal performance, minimizing weight, and ensuring cost-effectiveness. Innovations in material science are driving the development of new insulation solutions that offer enhanced thermal resistance, improved durability, and reduced environmental impact. As a result, the market for automotive thermal runaway insulation materials is poised for significant growth, driven by the increasing adoption of electric vehicles and the ongoing pursuit of safer, more efficient thermal management solutions.

Passenger Vehicles, Commercial Vehicles in the Global Automotive Thermal Runaway Insulation Materials Market:

The usage of Global Automotive Thermal Runaway Insulation Materials Market is particularly significant in the context of passenger vehicles and commercial vehicles, each with its unique set of requirements and challenges. In passenger vehicles, the primary focus is on ensuring the safety and comfort of the occupants while maximizing the vehicle's performance and efficiency. Thermal runaway insulation materials play a crucial role in managing the heat generated by the vehicle's battery system, preventing overheating, and ensuring the longevity of the battery. This is particularly important in electric passenger vehicles, where the battery is a critical component that directly impacts the vehicle's range and performance. By effectively managing the thermal environment within the battery compartment, these insulation materials help maintain optimal operating conditions, thereby enhancing the vehicle's overall efficiency and safety. In commercial vehicles, the demands on thermal runaway insulation materials are even more pronounced due to the larger size and higher power requirements of these vehicles. Commercial vehicles, such as trucks and buses, often operate under more demanding conditions, with longer operating hours and higher loads. As a result, the thermal management systems in these vehicles must be robust and reliable to ensure safe and efficient operation. Thermal runaway insulation materials are essential in preventing overheating and potential thermal runaway events, which could lead to costly downtime and repairs. Additionally, these materials help improve the energy efficiency of commercial vehicles by minimizing heat loss and optimizing the performance of the vehicle's battery system. This is particularly important in electric commercial vehicles, where maximizing range and minimizing energy consumption are critical considerations. The use of thermal runaway insulation materials in both passenger and commercial vehicles is driven by the need to comply with stringent safety regulations and meet the growing demand for electric vehicles. As the automotive industry continues to evolve, manufacturers are increasingly focusing on developing advanced insulation materials that offer superior thermal performance, lightweight properties, and cost-effectiveness. This involves leveraging the latest advancements in material science to create innovative solutions that can effectively manage thermal runaway risks while meeting the industry's rigorous safety standards. As a result, the Global Automotive Thermal Runaway Insulation Materials Market is poised for significant growth, driven by the increasing adoption of electric vehicles and the ongoing pursuit of safer, more efficient thermal management solutions.

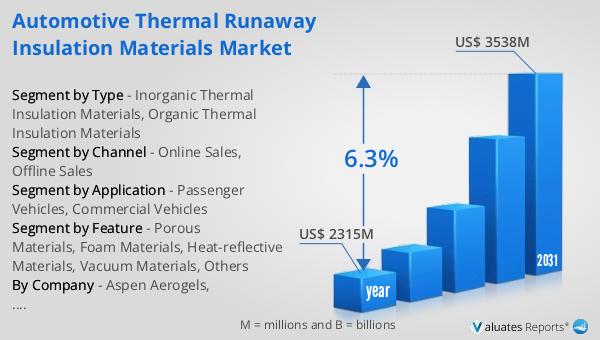

Global Automotive Thermal Runaway Insulation Materials Market Outlook:

The global market for Automotive Thermal Runaway Insulation Materials was valued at $2,315 million in 2024 and is anticipated to expand to a revised size of $3,538 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.3% over the forecast period. This growth trajectory underscores the increasing importance of thermal management solutions in the automotive industry, particularly as the shift towards electric vehicles gains momentum. The rising demand for electric vehicles, coupled with stringent safety regulations, is driving the need for advanced insulation materials that can effectively manage thermal runaway risks. As manufacturers strive to develop safer and more efficient vehicles, the demand for high-performance thermal insulation materials is expected to grow. This market expansion is further supported by ongoing innovations in material science, which are enabling the development of new insulation solutions that offer enhanced thermal resistance, improved durability, and reduced environmental impact. As a result, the Global Automotive Thermal Runaway Insulation Materials Market is poised for significant growth, driven by the increasing adoption of electric vehicles and the ongoing pursuit of safer, more efficient thermal management solutions.

| Report Metric | Details |

| Report Name | Automotive Thermal Runaway Insulation Materials Market |

| Accounted market size in year | US$ 2315 million |

| Forecasted market size in 2031 | US$ 3538 million |

| CAGR | 6.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Feature |

|

| Segment by Channel |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Aspen Aerogels, Alkegen, Rogers, Saint-Gobain, ElringKlinger, 3M, Avery Dennison, Shanghai Aerogelzone Technology, JBC Technologies, Shin-Etsu Chemical, Solvay, Henkel |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |