What is Global Lithium Battery Binders Market?

The Global Lithium Battery Binders Market is a crucial segment within the broader battery industry, focusing on materials that hold the active components of a battery together. These binders are essential for maintaining the structural integrity and performance of lithium batteries, which are widely used in various applications such as electric vehicles, consumer electronics, and renewable energy storage systems. The market for lithium battery binders is driven by the increasing demand for high-performance batteries that offer longer life cycles, higher energy densities, and improved safety features. As the world shifts towards more sustainable energy solutions, the demand for efficient and reliable lithium batteries continues to grow, thereby boosting the need for advanced binder materials. These binders are typically made from polymers that provide the necessary adhesion and flexibility to withstand the mechanical stresses during battery operation. The market is characterized by continuous research and development efforts aimed at enhancing the properties of binders to meet the evolving requirements of next-generation lithium batteries. With advancements in technology and increasing investments in battery research, the Global Lithium Battery Binders Market is poised for significant growth in the coming years.

SBR, PAA, PVDF, Others in the Global Lithium Battery Binders Market:

In the Global Lithium Battery Binders Market, several types of binders are used, each with its unique properties and applications. Among these, Styrene-Butadiene Rubber (SBR), Polyacrylic Acid (PAA), and Polyvinylidene Fluoride (PVDF) are the most prominent. SBR is a synthetic rubber that offers excellent flexibility and adhesion properties, making it a popular choice for use in lithium-ion batteries. It is particularly favored for its ability to enhance the mechanical stability of the electrode, which is crucial for maintaining battery performance over time. SBR is often used in combination with other materials to improve the overall efficiency and lifespan of the battery. Polyacrylic Acid (PAA), on the other hand, is known for its strong adhesive properties and high chemical stability. It is widely used in the production of lithium batteries due to its ability to provide a robust binding effect, which is essential for ensuring the durability and reliability of the battery. PAA is also valued for its environmental friendliness, as it is a water-based binder that reduces the need for harmful solvents in the manufacturing process. Polyvinylidene Fluoride (PVDF) is another key binder material in the lithium battery industry. It is renowned for its excellent chemical resistance and thermal stability, making it ideal for use in high-performance batteries that operate under demanding conditions. PVDF is often used in the production of both the positive and negative electrodes of lithium batteries, where it helps to enhance the overall energy density and cycle life of the battery. In addition to these primary binders, there are other materials used in the market, each offering specific benefits depending on the application. These include various copolymers and hybrid materials that are designed to optimize the performance of lithium batteries in different environments. The choice of binder material is critical in the design and manufacturing of lithium batteries, as it directly impacts the efficiency, safety, and longevity of the final product. As the demand for more advanced and sustainable energy storage solutions continues to rise, the development of innovative binder materials remains a key focus for researchers and manufacturers in the Global Lithium Battery Binders Market.

Negative Electrode, Positive Electrode, Separator in the Global Lithium Battery Binders Market:

The usage of binders in the Global Lithium Battery Binders Market is crucial for the performance and longevity of lithium batteries, particularly in the areas of the negative electrode, positive electrode, and separator. In the negative electrode, binders play a vital role in maintaining the structural integrity of the electrode material, which is typically composed of graphite or other carbon-based materials. The binder ensures that the active material remains adhered to the current collector, preventing detachment and degradation during the charge-discharge cycles. This is essential for maintaining the capacity and efficiency of the battery over its lifespan. In the positive electrode, binders are equally important, as they help to hold the active material, often composed of lithium metal oxides, in place. The binder must provide strong adhesion while also allowing for the expansion and contraction of the electrode material during operation. This flexibility is crucial for preventing mechanical failure and ensuring the long-term stability of the battery. The choice of binder material can significantly impact the energy density and cycle life of the battery, making it a critical consideration in the design and manufacturing process. In addition to the electrodes, binders are also used in the separator, which is a critical component of lithium batteries. The separator is responsible for preventing direct contact between the positive and negative electrodes while allowing for the flow of ions between them. Binders in the separator help to maintain its structural integrity and prevent shrinkage or deformation during operation. This is essential for ensuring the safety and reliability of the battery, as any failure in the separator can lead to short-circuiting and potential thermal runaway. Overall, the use of binders in lithium batteries is a key factor in determining their performance, safety, and longevity. As the demand for more efficient and reliable energy storage solutions continues to grow, the development of advanced binder materials remains a critical area of focus for researchers and manufacturers in the Global Lithium Battery Binders Market.

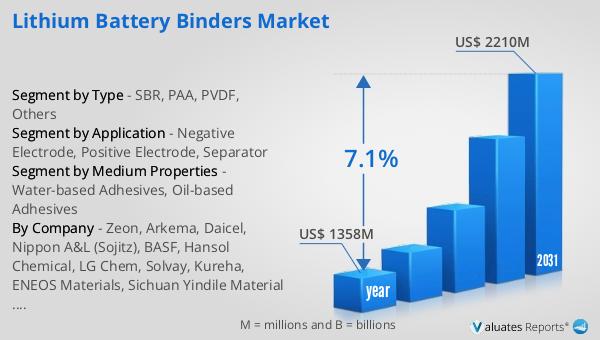

Global Lithium Battery Binders Market Outlook:

The global market for Lithium Battery Binders was valued at approximately $1,358 million in 2024, and it is anticipated to expand to a revised size of around $2,210 million by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 7.1% over the forecast period. This upward trend is indicative of the increasing demand for lithium batteries across various sectors, including electric vehicles, consumer electronics, and renewable energy storage systems. The market's expansion is driven by the need for high-performance batteries that offer longer life cycles, higher energy densities, and improved safety features. As industries continue to shift towards more sustainable and efficient energy solutions, the demand for advanced binder materials is expected to rise. These binders are essential for maintaining the structural integrity and performance of lithium batteries, which are critical components in the transition to a more sustainable energy future. The market is characterized by continuous research and development efforts aimed at enhancing the properties of binders to meet the evolving requirements of next-generation lithium batteries. With advancements in technology and increasing investments in battery research, the Global Lithium Battery Binders Market is poised for significant growth in the coming years.

| Report Metric | Details |

| Report Name | Lithium Battery Binders Market |

| Accounted market size in year | US$ 1358 million |

| Forecasted market size in 2031 | US$ 2210 million |

| CAGR | 7.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Medium Properties |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Zeon, Arkema, Daicel, Nippon A&L (Sojitz), BASF, Hansol Chemical, LG Chem, Solvay, Kureha, ENEOS Materials, Sichuan Yindile Material Technology, Nouryon, Shenzhen Yanyi New Materials, Trinseo, Synthomer, Hubei Huitian New Materials, Zhejiang Fluorine Chemical, Sinochem Lantian, Shandong Dongyue, Chongqing Lihong |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |