What is Global Gas Coriolis Mass Flow Meter Market?

The Global Gas Coriolis Mass Flow Meter Market refers to the worldwide industry focused on the production, distribution, and application of Coriolis mass flow meters specifically designed for measuring gas flow. These devices are highly valued for their precision and reliability in measuring the mass flow rate of gases, which is crucial in various industrial processes. Unlike traditional flow meters, Coriolis meters measure the mass flow directly, providing accurate readings regardless of changes in temperature, pressure, or gas composition. This makes them particularly useful in industries where precise measurement is critical, such as oil and gas, chemical processing, and food and beverage production. The market encompasses a range of products, from simple models for basic applications to advanced systems with sophisticated features for complex industrial environments. As industries continue to prioritize efficiency and accuracy, the demand for Coriolis mass flow meters is expected to grow, driven by technological advancements and the increasing need for precise gas measurement solutions. The market is characterized by a diverse range of manufacturers and suppliers, each offering unique products tailored to specific industry needs. Overall, the Global Gas Coriolis Mass Flow Meter Market plays a vital role in enhancing operational efficiency and ensuring accurate measurement across various sectors.

Double Bend Pipe, Single Straight Pipe, Other in the Global Gas Coriolis Mass Flow Meter Market:

In the Global Gas Coriolis Mass Flow Meter Market, different types of pipe configurations are used to accommodate various industrial needs and applications. Among these, the Double Bend Pipe, Single Straight Pipe, and other configurations are prominent. The Double Bend Pipe design is characterized by its two bends, which allow for a compact installation in spaces where a straight pipe might not fit. This configuration is particularly useful in industries where space is limited, and the flow path needs to be adjusted to fit within existing infrastructure. The bends in the pipe help in maintaining the flow dynamics required for accurate measurement, ensuring that the Coriolis effect is effectively utilized to measure the mass flow rate of gases. On the other hand, the Single Straight Pipe configuration is designed for applications where space is not a constraint, and a straight flow path is preferred. This design is often used in industries where the flow conditions are stable, and there is a need for minimal pressure drop across the flow meter. The straight pipe allows for a more straightforward installation and maintenance process, making it a popular choice in many industrial settings. Additionally, the Single Straight Pipe design is known for its high accuracy and reliability, as it minimizes the potential for flow disturbances that can affect measurement precision. Apart from these two configurations, there are other designs available in the market that cater to specific industrial requirements. These may include custom pipe configurations that are tailored to meet the unique needs of a particular application or industry. For instance, some industries may require flow meters with specialized coatings or materials to withstand corrosive environments or high temperatures. In such cases, manufacturers offer customized solutions that incorporate these features into the pipe design, ensuring that the flow meter can operate effectively under challenging conditions. The choice of pipe configuration in the Global Gas Coriolis Mass Flow Meter Market is influenced by several factors, including the nature of the gas being measured, the operating conditions, and the specific requirements of the application. Each configuration offers distinct advantages and is suited to different types of installations and measurement needs. As the market continues to evolve, manufacturers are investing in research and development to enhance the performance and versatility of these flow meters, ensuring that they can meet the diverse demands of modern industrial processes. Overall, the variety of pipe configurations available in the Global Gas Coriolis Mass Flow Meter Market reflects the industry's commitment to providing accurate and reliable measurement solutions for a wide range of applications.

Oil & Gas, Chemical & Petrochemical, Industrial Gases, Food & Beverage, Other in the Global Gas Coriolis Mass Flow Meter Market:

The Global Gas Coriolis Mass Flow Meter Market finds extensive usage across various industries, each benefiting from the precision and reliability these devices offer. In the Oil & Gas sector, Coriolis mass flow meters are indispensable for measuring the flow of natural gas and other hydrocarbons. Their ability to provide accurate mass flow measurements regardless of changes in pressure and temperature makes them ideal for custody transfer applications, where precise measurement is crucial for financial transactions. Additionally, these meters are used in monitoring and controlling gas flow in pipelines, ensuring efficient and safe operations. In the Chemical & Petrochemical industry, Coriolis mass flow meters are used to measure the flow of gases involved in chemical reactions and processes. Their high accuracy and ability to handle a wide range of flow rates make them suitable for applications such as gas blending, where precise measurement is essential to maintain product quality and consistency. The meters' ability to measure mass flow directly also helps in optimizing chemical processes, reducing waste, and improving overall efficiency. In the Industrial Gases sector, Coriolis mass flow meters are used to measure the flow of gases such as oxygen, nitrogen, and hydrogen. These gases are often used in various industrial applications, including welding, cutting, and chemical synthesis. The meters' ability to provide accurate and reliable measurements ensures that the correct amount of gas is delivered to the process, enhancing safety and efficiency. In the Food & Beverage industry, Coriolis mass flow meters are used to measure the flow of gases used in packaging and processing. For example, carbon dioxide is often used in the carbonation of beverages, and precise measurement is essential to ensure product quality. The meters' ability to measure mass flow directly, without being affected by changes in temperature or pressure, makes them ideal for these applications. Additionally, their hygienic design and ease of cleaning make them suitable for use in food processing environments. Beyond these industries, Coriolis mass flow meters are used in various other applications, including environmental monitoring, pharmaceuticals, and power generation. Their versatility and ability to provide accurate measurements in challenging conditions make them a valuable tool in any industry where gas flow measurement is required. As industries continue to seek ways to improve efficiency and reduce costs, the demand for Coriolis mass flow meters is expected to grow, driven by their ability to provide precise and reliable measurements across a wide range of applications.

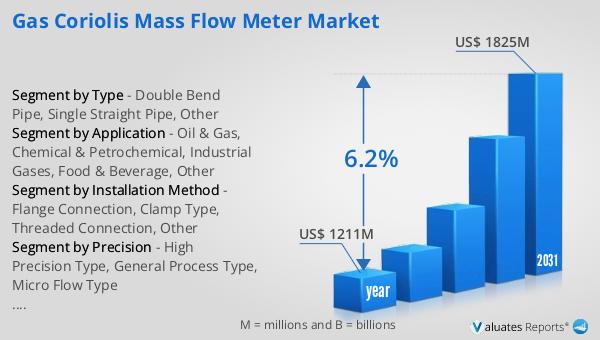

Global Gas Coriolis Mass Flow Meter Market Outlook:

The global market for Gas Coriolis Mass Flow Meters was valued at $1,211 million in 2024 and is anticipated to expand to a revised size of $1,825 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.2% over the forecast period. This growth trajectory underscores the increasing demand for accurate and reliable gas flow measurement solutions across various industries. The rising adoption of Coriolis mass flow meters can be attributed to their superior accuracy, reliability, and ability to measure mass flow directly, which is crucial for optimizing industrial processes and ensuring product quality. As industries continue to prioritize efficiency and precision, the demand for these advanced flow meters is expected to rise, driving market growth. The market's expansion is also supported by technological advancements and the development of new applications for Coriolis mass flow meters, further enhancing their appeal to a wide range of industries. Overall, the Global Gas Coriolis Mass Flow Meter Market is poised for significant growth, driven by the increasing need for precise gas measurement solutions and the ongoing advancements in flow measurement technology.

| Report Metric | Details |

| Report Name | Gas Coriolis Mass Flow Meter Market |

| Accounted market size in year | US$ 1211 million |

| Forecasted market size in 2031 | US$ 1825 million |

| CAGR | 6.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Precision |

|

| Segment by Installation Method |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Endress+Hauser, Emerson, Siemens, Yokogawa, ABB, KROHNE, Schneider Electric, Honeywell, Azbil, Brooks Instrument, Rheonik, OVAL Corporation, Fuji Electric, Badger Meter, Bronkhorst, Systec Controls, Shanghai Yinuo, Beijing Sincerity |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |