What is Global Aircraft Carbon Fiber Reinforced Plastic (CFRP) Components Market?

The Global Aircraft Carbon Fiber Reinforced Plastic (CFRP) Components Market is a specialized segment within the aerospace industry that focuses on the use of advanced composite materials to enhance the performance and efficiency of aircraft. CFRP components are made by reinforcing plastic with carbon fibers, which results in a material that is both lightweight and incredibly strong. This combination of properties makes CFRP an ideal choice for various aircraft parts, including wings, fuselage sections, and interior components. The use of CFRP in aircraft manufacturing helps reduce the overall weight of the aircraft, leading to improved fuel efficiency and reduced emissions. Additionally, CFRP components offer excellent resistance to fatigue and corrosion, which enhances the durability and longevity of aircraft. As the aerospace industry continues to prioritize sustainability and performance, the demand for CFRP components is expected to grow, driven by advancements in manufacturing technologies and the increasing adoption of these materials in both commercial and military aviation sectors. The market is characterized by ongoing research and development efforts aimed at further improving the properties and cost-effectiveness of CFRP materials, making them more accessible for a wider range of applications within the aviation industry.

Thermoset CFRP Components, Thermoplastic CFRP Components in the Global Aircraft Carbon Fiber Reinforced Plastic (CFRP) Components Market:

Thermoset CFRP components and thermoplastic CFRP components are two primary categories within the Global Aircraft Carbon Fiber Reinforced Plastic (CFRP) Components Market, each offering distinct advantages and applications. Thermoset CFRP components are created using a resin that cures and hardens when exposed to heat, resulting in a rigid and durable material. This type of CFRP is known for its excellent thermal stability and resistance to high temperatures, making it suitable for structural applications in aircraft where strength and stability are critical. Thermoset CFRP is commonly used in the production of aircraft wings, fuselage sections, and other load-bearing components due to its ability to maintain structural integrity under stress. On the other hand, thermoplastic CFRP components are made using a resin that becomes pliable when heated and hardens upon cooling. This characteristic allows for easier reshaping and recycling of the material, making thermoplastic CFRP an attractive option for applications where flexibility and sustainability are important. Thermoplastic CFRP is often used in the production of interior components, such as seat frames and cabin panels, where ease of manufacturing and the potential for recycling are key considerations. The choice between thermoset and thermoplastic CFRP components depends on the specific requirements of the application, including factors such as weight, strength, temperature resistance, and cost. Both types of CFRP components contribute to the overall performance and efficiency of aircraft by reducing weight and enhancing durability, ultimately leading to improved fuel efficiency and reduced environmental impact. As the aerospace industry continues to evolve, the development and adoption of advanced CFRP materials are expected to play a crucial role in meeting the demands for more efficient and sustainable aircraft. The ongoing research and innovation in CFRP technologies are likely to result in new formulations and manufacturing processes that further enhance the properties and applications of these materials, making them an integral part of the future of aviation.

Commercial Aircraft, Military Aircraft, Helicopters, Drones in the Global Aircraft Carbon Fiber Reinforced Plastic (CFRP) Components Market:

The usage of Global Aircraft Carbon Fiber Reinforced Plastic (CFRP) Components Market spans across various segments of the aviation industry, including commercial aircraft, military aircraft, helicopters, and drones. In commercial aircraft, CFRP components are extensively used to reduce the overall weight of the aircraft, which directly translates to improved fuel efficiency and lower operating costs. Airlines benefit from the reduced fuel consumption, which not only lowers expenses but also contributes to a decrease in carbon emissions, aligning with global sustainability goals. CFRP components in commercial aircraft are typically found in the wings, fuselage, and tail sections, where their strength and lightweight properties are most advantageous. In military aircraft, the use of CFRP components is driven by the need for enhanced performance and maneuverability. The lightweight nature of CFRP allows for increased payload capacity and extended range, which are critical factors in military operations. Additionally, the durability and resistance to fatigue offered by CFRP components ensure that military aircraft can withstand the demanding conditions of combat and training missions. Helicopters also benefit from the use of CFRP components, particularly in rotor blades and structural elements. The reduced weight of CFRP components contributes to improved lift and fuel efficiency, which are essential for the operational effectiveness of helicopters. Furthermore, the vibration-damping properties of CFRP materials enhance the comfort and safety of helicopter flights. In the rapidly growing drone industry, CFRP components are favored for their lightweight and strong characteristics, which are crucial for maximizing flight time and payload capacity. Drones equipped with CFRP components can achieve longer flight durations and carry heavier loads, making them more versatile for various applications, including surveillance, delivery, and aerial photography. The adoption of CFRP components in drones also supports the development of more efficient and environmentally friendly unmanned aerial vehicles. Overall, the use of CFRP components across these different aviation sectors highlights the material's versatility and its significant contribution to advancing the performance, efficiency, and sustainability of modern aircraft.

Global Aircraft Carbon Fiber Reinforced Plastic (CFRP) Components Market Outlook:

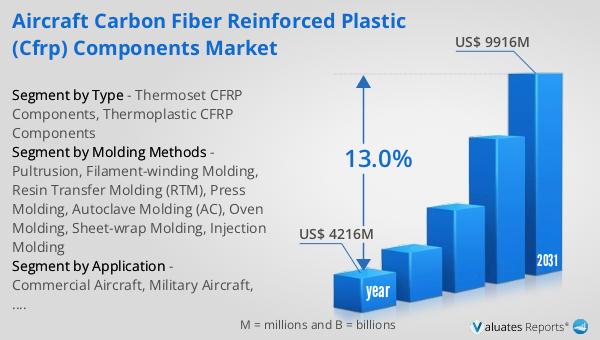

The global market for Aircraft Carbon Fiber Reinforced Plastic (CFRP) Components was valued at $4,216 million in 2024, and it is anticipated to expand significantly, reaching an estimated $9,916 million by 2031. This growth represents a compound annual growth rate (CAGR) of 13.0% over the forecast period. This impressive growth trajectory underscores the increasing demand for CFRP components in the aerospace industry, driven by the need for more efficient and sustainable aircraft. The lightweight and durable nature of CFRP materials make them an ideal choice for various applications within the aviation sector, contributing to improved fuel efficiency and reduced emissions. As airlines and aircraft manufacturers continue to prioritize sustainability and performance, the adoption of CFRP components is expected to rise, further fueling market growth. The ongoing advancements in manufacturing technologies and the development of new CFRP formulations are likely to enhance the properties and cost-effectiveness of these materials, making them more accessible for a wider range of applications. This market outlook highlights the significant role that CFRP components are poised to play in the future of aviation, as the industry continues to evolve and adapt to changing demands and environmental considerations.

| Report Metric | Details |

| Report Name | Aircraft Carbon Fiber Reinforced Plastic (CFRP) Components Market |

| Accounted market size in year | US$ 4216 million |

| Forecasted market size in 2031 | US$ 9916 million |

| CAGR | 13.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Installation Location |

|

| Segment by Molding Methods |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Spirit AeroSystems, GKN Aerospace, FACC AG, Hexcel, Applied Composites, Kaman Composites, Royal Engineered Composites, Nammo Composite Solutions, FDC Aero Composites, Terma, Alestis Aerospace, SGL Carbon, Aerodine Composites, Composiflex, Heico Corporation, Hankuk Carbon, Weihai Guangwei Composites, HRC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |