What is Global CFRP Aerostructures Market?

The Global CFRP Aerostructures Market refers to the worldwide industry focused on the production and sale of carbon fiber reinforced polymer (CFRP) components used in the construction of aircraft structures. These components are integral to the aerospace industry due to their lightweight and high-strength properties, which contribute to improved fuel efficiency and performance of aircraft. CFRP aerostructures are used in various parts of an aircraft, including wings, fuselage, and tail sections. The market is driven by the increasing demand for fuel-efficient aircraft, advancements in composite material technology, and the growing aerospace industry. As airlines and military organizations seek to reduce operational costs and environmental impact, the adoption of CFRP aerostructures is expected to rise. The market encompasses a range of activities, from the manufacturing of raw materials to the assembly of finished components, and involves numerous stakeholders, including material suppliers, component manufacturers, and aircraft producers. The global CFRP aerostructures market is characterized by continuous innovation and collaboration among industry players to enhance the performance and cost-effectiveness of these advanced materials.

Thermoset CFRP Aerostructures, Thermoplastic CFRP Aerostructures in the Global CFRP Aerostructures Market:

Thermoset CFRP aerostructures are a significant segment within the Global CFRP Aerostructures Market, known for their durability and resistance to high temperatures. These structures are made by impregnating carbon fibers with a thermosetting resin, which hardens when cured, creating a strong and stable composite material. The curing process involves applying heat and pressure, which causes the resin to cross-link and form a rigid matrix that binds the fibers together. This results in a material that is not only lightweight but also capable of withstanding the stresses and strains experienced during flight. Thermoset CFRP aerostructures are commonly used in critical aircraft components such as wings and fuselage sections, where their high strength-to-weight ratio and resistance to fatigue are essential. On the other hand, thermoplastic CFRP aerostructures offer a different set of advantages. These structures are made using thermoplastic resins, which can be melted and reformed multiple times without degrading the material's properties. This characteristic allows for greater flexibility in manufacturing processes, as components can be reshaped or repaired more easily than their thermoset counterparts. Thermoplastic CFRP aerostructures are particularly valued for their impact resistance and toughness, making them suitable for applications where durability and damage tolerance are crucial. Additionally, the ability to recycle thermoplastic composites aligns with the growing emphasis on sustainability within the aerospace industry. Both thermoset and thermoplastic CFRP aerostructures play vital roles in the development of modern aircraft, each offering unique benefits that cater to specific design and performance requirements. The choice between the two often depends on factors such as the intended application, manufacturing capabilities, and cost considerations. As the aerospace industry continues to evolve, the demand for advanced materials like CFRP aerostructures is expected to grow, driven by the need for more efficient and environmentally friendly aircraft. Manufacturers are continually exploring new resin formulations and fiber architectures to enhance the performance of both thermoset and thermoplastic composites, ensuring that they meet the ever-increasing demands of the market. The ongoing research and development efforts in this field are likely to yield innovative solutions that further expand the capabilities and applications of CFRP aerostructures in the aerospace sector.

Commercial, Military, Other in the Global CFRP Aerostructures Market:

The usage of Global CFRP Aerostructures Market extends across various sectors, including commercial aviation, military applications, and other specialized areas. In the commercial aviation sector, CFRP aerostructures are increasingly being adopted to enhance the performance and efficiency of passenger and cargo aircraft. Airlines are under constant pressure to reduce fuel consumption and emissions, and the lightweight nature of CFRP components plays a crucial role in achieving these goals. By incorporating CFRP aerostructures into the design of aircraft, manufacturers can reduce the overall weight of the plane, leading to significant fuel savings and a reduction in greenhouse gas emissions. This not only helps airlines meet regulatory requirements but also contributes to their sustainability initiatives. In the military sector, CFRP aerostructures are used in the development of advanced fighter jets, transport aircraft, and unmanned aerial vehicles (UAVs). The high strength-to-weight ratio of CFRP materials allows for the construction of agile and maneuverable aircraft that can carry heavier payloads and operate more efficiently. Additionally, the stealth capabilities of military aircraft can be enhanced through the use of CFRP composites, which can be engineered to absorb radar waves and reduce the aircraft's detectability. This makes CFRP aerostructures a valuable asset in modern military aviation, where performance and survivability are paramount. Beyond commercial and military applications, CFRP aerostructures are also utilized in other areas such as space exploration and the development of specialized aircraft for scientific research. In the space industry, the lightweight and durable nature of CFRP materials make them ideal for constructing satellite components and launch vehicle structures. The ability to withstand the harsh conditions of space, including extreme temperatures and radiation, is a testament to the robustness of CFRP composites. Similarly, in scientific research, CFRP aerostructures are used in the design of aircraft that require precise performance characteristics, such as those used in atmospheric studies or environmental monitoring. The versatility and adaptability of CFRP aerostructures make them an indispensable component in the advancement of aerospace technology across various sectors.

Global CFRP Aerostructures Market Outlook:

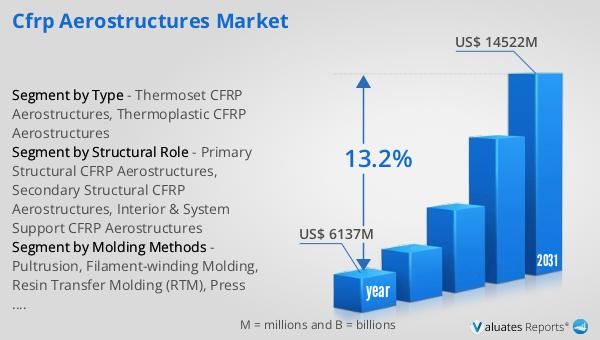

The global market for CFRP Aerostructures was valued at $6,137 million in 2024 and is anticipated to expand to a revised size of $14,522 million by 2031, reflecting a compound annual growth rate (CAGR) of 13.2% over the forecast period. This significant growth underscores the increasing demand for lightweight and high-performance materials in the aerospace industry. As airlines and military organizations strive to enhance fuel efficiency and reduce emissions, the adoption of CFRP aerostructures is expected to accelerate. The market's expansion is also driven by advancements in composite material technology, which continue to improve the performance and cost-effectiveness of CFRP components. The projected growth of the CFRP aerostructures market highlights the industry's commitment to innovation and sustainability, as manufacturers and stakeholders collaborate to develop cutting-edge solutions that meet the evolving needs of the aerospace sector. This growth trajectory reflects the broader trend towards the use of advanced materials in aircraft design, as the industry seeks to balance performance, efficiency, and environmental impact. The increasing adoption of CFRP aerostructures is a testament to their critical role in shaping the future of aviation, as they enable the development of more efficient and environmentally friendly aircraft.

| Report Metric | Details |

| Report Name | CFRP Aerostructures Market |

| Accounted market size in year | US$ 6137 million |

| Forecasted market size in 2031 | US$ 14522 million |

| CAGR | 13.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Structural Role |

|

| Segment by Molding Methods |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Spirit AeroSystems, GKN Aerospace, FACC AG, Hexcel, Applied Composites, Kaman Composites, Royal Engineered Composites, Nammo Composite Solutions, FDC Aero Composites, Terma, Aciturri, SGL Carbon, Aerodine Composites, Composiflex, Heico Corporation, Hankuk Carbon, Weihai Guangwei Composites |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |