What is Global Pulse MIG/MAG Welding Machine Market?

The Global Pulse MIG/MAG Welding Machine Market refers to the worldwide industry focused on the production and distribution of welding machines that utilize pulse technology in Metal Inert Gas (MIG) and Metal Active Gas (MAG) welding processes. These machines are designed to enhance the welding process by providing better control over the heat input, which results in improved weld quality and reduced spatter. Pulse MIG/MAG welding machines are particularly beneficial in applications where precision and efficiency are paramount, such as in the automotive, aerospace, and electronics industries. The market for these machines is driven by the increasing demand for high-quality welding solutions that can meet the stringent requirements of modern manufacturing processes. Additionally, advancements in technology have led to the development of more sophisticated welding machines that offer enhanced features and capabilities, further fueling the growth of the market. As industries continue to seek ways to improve productivity and reduce costs, the adoption of pulse MIG/MAG welding machines is expected to rise, making this market a key area of interest for manufacturers and investors alike.

Single Pulse, Double Pulse, Multi-pulse in the Global Pulse MIG/MAG Welding Machine Market:

In the realm of Global Pulse MIG/MAG Welding Machine Market, the terms Single Pulse, Double Pulse, and Multi-pulse refer to different modes of operation that these machines can utilize to achieve specific welding outcomes. Single Pulse welding is the most basic form, where a single pulse of current is applied to the weld pool. This mode is particularly useful for thin materials and applications where minimal heat input is required. It allows for precise control over the welding process, reducing the risk of burn-through and distortion. Single Pulse is often used in applications where aesthetics are important, as it produces a clean and smooth weld bead with minimal spatter. On the other hand, Double Pulse welding involves the use of two distinct pulses of current. The first pulse is typically higher in energy and is used to penetrate the material, while the second pulse is lower in energy and is used to refine the weld pool. This mode is ideal for thicker materials and applications where a strong and durable weld is required. Double Pulse welding is known for its ability to produce high-quality welds with excellent mechanical properties, making it a popular choice in industries such as automotive and aerospace. Multi-pulse welding takes this concept a step further by using multiple pulses of varying energy levels to achieve even greater control over the welding process. This mode is particularly beneficial in complex welding applications where precise control over the heat input is critical. Multi-pulse welding allows for the fine-tuning of the weld pool, resulting in superior weld quality and reduced defects. It is often used in high-tech industries such as electronics and medical device manufacturing, where precision and reliability are paramount. The choice between Single Pulse, Double Pulse, and Multi-pulse modes depends on the specific requirements of the welding application, including the type of material being welded, the desired weld quality, and the production environment. As the Global Pulse MIG/MAG Welding Machine Market continues to evolve, manufacturers are developing more advanced machines that offer greater flexibility and control over these pulse modes, enabling users to achieve optimal welding results in a wide range of applications.

Automotive Industry, Machinery Industry, Aerospace Industry, Electronics Industry, Others in the Global Pulse MIG/MAG Welding Machine Market:

The Global Pulse MIG/MAG Welding Machine Market finds extensive usage across various industries, each with its unique set of requirements and challenges. In the automotive industry, these welding machines are crucial for the production of lightweight and high-strength components. The precision and control offered by pulse welding technology allow manufacturers to produce welds that meet the stringent safety and performance standards of modern vehicles. This is particularly important in the production of electric vehicles, where weight reduction and structural integrity are critical. In the machinery industry, pulse MIG/MAG welding machines are used to fabricate a wide range of equipment and components. The ability to produce high-quality welds with minimal distortion is essential in this industry, where precision and durability are key. These machines are often used in the production of heavy machinery, agricultural equipment, and construction tools, where robust and reliable welds are necessary to withstand harsh operating conditions. The aerospace industry also relies heavily on pulse MIG/MAG welding machines for the production of aircraft components. The high precision and control offered by these machines are essential for meeting the strict quality and safety standards of the aerospace sector. Pulse welding technology allows for the production of lightweight and high-strength components, which are critical for improving fuel efficiency and performance in modern aircraft. In the electronics industry, pulse MIG/MAG welding machines are used to produce delicate and intricate components. The ability to control the heat input precisely is crucial in this industry, where even minor defects can lead to significant performance issues. These machines are often used in the production of circuit boards, connectors, and other electronic components, where precision and reliability are paramount. Beyond these industries, pulse MIG/MAG welding machines are also used in various other applications, including the production of medical devices, consumer electronics, and renewable energy systems. The versatility and adaptability of these machines make them an invaluable tool in a wide range of manufacturing processes, where high-quality welds are essential for ensuring product performance and reliability. As the demand for advanced manufacturing solutions continues to grow, the usage of pulse MIG/MAG welding machines is expected to expand across various industries, driving further innovation and development in this market.

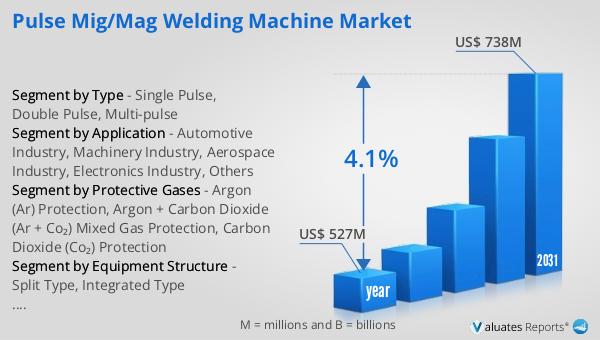

Global Pulse MIG/MAG Welding Machine Market Outlook:

The global market for Pulse MIG/MAG Welding Machines was valued at approximately $527 million in 2024. This market is anticipated to grow steadily, reaching an estimated size of $738 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.1% over the forecast period. The increasing demand for high-quality welding solutions across various industries is a significant factor driving this growth. As industries such as automotive, aerospace, and electronics continue to evolve, the need for advanced welding technologies that offer precision, efficiency, and reliability becomes more critical. Pulse MIG/MAG welding machines, with their ability to provide superior weld quality and control, are well-positioned to meet these demands. Additionally, advancements in welding technology and the development of more sophisticated machines are expected to further fuel market growth. Manufacturers are focusing on enhancing the features and capabilities of these machines to cater to the diverse needs of different industries. As a result, the Global Pulse MIG/MAG Welding Machine Market is poised for continued expansion, offering significant opportunities for manufacturers, investors, and other stakeholders. The steady growth of this market underscores the importance of pulse welding technology in modern manufacturing processes and its potential to drive innovation and efficiency across various sectors.

| Report Metric | Details |

| Report Name | Pulse MIG/MAG Welding Machine Market |

| Accounted market size in year | US$ 527 million |

| Forecasted market size in 2031 | US$ 738 million |

| CAGR | 4.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Protective Gases |

|

| Segment by Equipment Structure |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | REHM, Headux, Lincoln Electric, ESAB, Miller Welding, Kaierda, American Torch Tip, Panasonic, WELDTEC, TOYOR HEAVY INDUSTRY GROUP, SHANGHAI HUGONG, RILAND, MAGMEET, SAN QIAO SY, SHANGHAI DONSUN WELDING GROUP, JINRUI WELDING EQUIPMENT, CHD WELDING, AOTAI, HUAAO WELDING MACHINE, Floma, Chengdu Welding Research Taike Intelligent Manufacturing, Keygree Group, Dynaweld |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |