What is Global Rubber Covered Rollers Market?

The Global Rubber Covered Rollers Market is a significant segment within the industrial manufacturing sector, encompassing a wide range of applications across various industries. Rubber covered rollers are essential components used in machinery for processing, conveying, and handling materials. These rollers are typically made by covering a metal core with a layer of rubber, which provides the necessary grip, cushioning, and resistance to wear and tear. The market for these rollers is driven by the demand from industries such as textiles, paper, printing, steel, and food processing, where they play a crucial role in ensuring smooth and efficient operations. The versatility of rubber covered rollers, in terms of their ability to be customized for specific applications, makes them indispensable in many industrial processes. As industries continue to evolve and seek more efficient and durable solutions, the demand for high-quality rubber covered rollers is expected to grow. This market is characterized by a diverse range of products, each designed to meet the specific needs of different applications, thereby contributing to the overall growth and development of the industrial sector.

Synthetic Rubber Roller, Natural Rubber Roller, Epdm Rubber Roller, Silicone Rubber Roller, Neoprene Roller, Other Rubber Rollers in the Global Rubber Covered Rollers Market:

In the Global Rubber Covered Rollers Market, various types of rubber rollers are utilized, each offering unique properties and benefits tailored to specific industrial needs. Synthetic rubber rollers are among the most commonly used, known for their durability and resistance to chemicals and extreme temperatures. These rollers are ideal for applications that require high performance and longevity, such as in the printing and packaging industries. Natural rubber rollers, on the other hand, are valued for their excellent elasticity and flexibility, making them suitable for applications where a softer touch is needed, such as in textile manufacturing. EPDM (Ethylene Propylene Diene Monomer) rubber rollers are particularly favored for their outstanding resistance to weathering, ozone, and UV rays, making them ideal for outdoor applications or environments exposed to harsh conditions. Silicone rubber rollers are renowned for their heat resistance and non-stick properties, making them perfect for applications in the food processing industry where hygiene and temperature stability are crucial. Neoprene rollers offer a balance of chemical resistance and mechanical strength, making them versatile for various industrial applications, including metal processing and automotive manufacturing. Other rubber rollers, such as those made from nitrile or polyurethane, provide specialized solutions for niche applications, offering unique combinations of hardness, resilience, and resistance to specific chemicals or environmental conditions. Each type of rubber roller is designed to meet the specific demands of its intended application, ensuring optimal performance and efficiency in industrial processes. The diversity of rubber rollers available in the market allows industries to select the most appropriate solution for their specific needs, contributing to the overall efficiency and productivity of their operations.

Textile Industry, Paper Industry, Iron and Steel Industry, Food Processing Industry, Quarrying Industry, Other in the Global Rubber Covered Rollers Market:

The Global Rubber Covered Rollers Market finds extensive usage across a variety of industries, each benefiting from the unique properties and advantages offered by these rollers. In the textile industry, rubber covered rollers are essential for processes such as dyeing, printing, and finishing, where they help ensure uniform application and smooth handling of fabrics. The elasticity and grip provided by rubber rollers are crucial for maintaining the quality and consistency of textile products. In the paper industry, these rollers play a vital role in the production and processing of paper, where they are used in machines for calendering, coating, and embossing. The durability and precision of rubber rollers help achieve the desired texture and finish of paper products. The iron and steel industry also relies heavily on rubber covered rollers, particularly in processes such as rolling, coating, and galvanizing, where they help ensure the smooth and efficient handling of heavy metal sheets and coils. In the food processing industry, rubber rollers are used in various applications, including dough handling, packaging, and labeling, where their non-stick and hygienic properties are essential for maintaining food safety and quality. The quarrying industry benefits from the use of rubber rollers in conveyor systems, where they help transport heavy materials such as rocks and minerals with minimal wear and tear. Other industries, such as automotive, printing, and packaging, also utilize rubber covered rollers for their specific needs, benefiting from the versatility and adaptability of these components. The widespread use of rubber covered rollers across different industries highlights their importance in ensuring efficient and reliable operations, contributing to the overall productivity and success of industrial processes.

Global Rubber Covered Rollers Market Outlook:

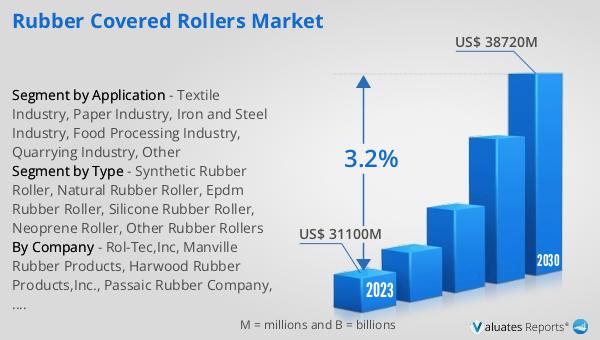

The outlook for the Global Rubber Covered Rollers Market indicates a promising growth trajectory over the coming years. In 2024, the market was valued at approximately US$ 33,010 million, reflecting its significant role in various industrial applications. By 2031, the market is projected to expand to a revised size of US$ 40,970 million, driven by a compound annual growth rate (CAGR) of 3.2% during the forecast period. This growth can be attributed to the increasing demand for efficient and durable solutions in industries such as textiles, paper, steel, and food processing, where rubber covered rollers play a crucial role in enhancing operational efficiency and product quality. The market's expansion is also supported by advancements in rubber technology, which have led to the development of more specialized and high-performance rollers tailored to meet the specific needs of different applications. As industries continue to evolve and seek innovative solutions to improve their processes, the demand for high-quality rubber covered rollers is expected to rise, contributing to the overall growth and development of the market. The projected growth of the Global Rubber Covered Rollers Market underscores the importance of these components in ensuring the smooth and efficient operation of industrial processes, highlighting their indispensable role in the modern industrial landscape.

| Report Metric | Details |

| Report Name | Rubber Covered Rollers Market |

| Accounted market size in year | US$ 33010 million |

| Forecasted market size in 2031 | US$ 40970 million |

| CAGR | 3.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Rol-Tec,Inc, Manville Rubber Products, Harwood Rubber Products,Inc., Passaic Rubber Company, Columbia Rubber Mills, Valley Roller, Rubber Coated Rollers, Krishna Engineering Works, ADVANCE RUBTECH (I) PRIVATE LIMITED, REDCO Rubber Engineering&Development, Vintex Rubber Industries, Warca Rulli Srl, Ames Rubber Manufacturing, Rubber Right Rollers, J.J. Short Associates,Inc |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |