What is Global Functional Hydrogel Coating Market?

The Global Functional Hydrogel Coating Market is a rapidly evolving sector that focuses on the development and application of hydrogel coatings with functional properties. These coatings are primarily composed of hydrophilic polymer networks that can retain a significant amount of water while maintaining their structural integrity. The unique properties of hydrogels, such as their biocompatibility, flexibility, and ability to respond to environmental stimuli, make them highly desirable for various applications. In the global market, functional hydrogel coatings are utilized across diverse industries, including medical, electronics, and chemical sectors, due to their ability to enhance product performance and longevity. The market is driven by continuous advancements in material science and technology, which enable the creation of more sophisticated and efficient hydrogel coatings. As industries seek innovative solutions to improve their products, the demand for functional hydrogel coatings is expected to grow, offering new opportunities for manufacturers and researchers alike. The versatility and adaptability of these coatings ensure their relevance in addressing contemporary challenges across multiple fields, making them a crucial component in the advancement of modern technology and healthcare solutions.

Medical Use, Non-Medical Use in the Global Functional Hydrogel Coating Market:

In the realm of medical applications, functional hydrogel coatings play a pivotal role in enhancing the performance and safety of various medical devices and treatments. These coatings are often applied to medical instruments, implants, and wound dressings to improve their biocompatibility and reduce the risk of infection. For instance, hydrogel coatings on catheters and stents can minimize friction and prevent bacterial adhesion, thereby reducing the likelihood of complications during medical procedures. Additionally, hydrogels are used in drug delivery systems, where their ability to swell and release therapeutic agents in a controlled manner is highly beneficial. This controlled release mechanism ensures that medications are delivered at the optimal rate and concentration, improving patient outcomes and reducing side effects. Beyond medical devices, functional hydrogel coatings are also employed in tissue engineering and regenerative medicine. Their ability to mimic the extracellular matrix and support cell growth makes them ideal for creating scaffolds that facilitate tissue repair and regeneration. In non-medical applications, functional hydrogel coatings are utilized in a variety of industries to enhance product performance and durability. In the electronics sector, these coatings are used to protect sensitive components from moisture and environmental damage. Their ability to absorb and retain water makes them effective barriers against humidity, which can otherwise lead to corrosion and malfunction of electronic devices. Similarly, in the semiconductor industry, hydrogel coatings are applied to protect delicate circuits and components from contamination and mechanical stress. The chemical industry also benefits from the unique properties of functional hydrogel coatings. These coatings are used to improve the efficiency of chemical reactions by providing a controlled environment for reactants. Their ability to swell and contract in response to changes in temperature or pH can be harnessed to regulate reaction rates and enhance product yield. Furthermore, in the machinery sector, hydrogel coatings are applied to reduce friction and wear on moving parts, thereby extending the lifespan of equipment and reducing maintenance costs. The versatility of functional hydrogel coatings makes them an invaluable tool across a wide range of applications, driving innovation and efficiency in both medical and non-medical fields. As research and development efforts continue to advance, the potential uses for these coatings are expected to expand, offering new solutions to complex challenges in various industries.

Medicine, Medical Instruments, Electronic, Semiconductor, Chemical, Machinery in the Global Functional Hydrogel Coating Market:

The usage of Global Functional Hydrogel Coating Market spans across several key areas, including medicine, medical instruments, electronics, semiconductors, chemicals, and machinery. In the field of medicine, hydrogel coatings are primarily used to enhance the biocompatibility and functionality of medical devices. For example, they are applied to implants and prosthetics to reduce the risk of rejection and improve integration with the body's tissues. The hydrophilic nature of these coatings allows them to retain moisture, which is crucial for maintaining the health and viability of surrounding tissues. In addition to implants, hydrogel coatings are also used in wound care products, where they provide a moist environment that promotes healing and reduces the risk of infection. In the realm of medical instruments, functional hydrogel coatings are used to improve the performance and safety of devices such as catheters, syringes, and surgical tools. These coatings reduce friction and prevent the adhesion of proteins and bacteria, thereby minimizing the risk of complications during medical procedures. In the electronics industry, hydrogel coatings are used to protect sensitive components from moisture and environmental damage. Their ability to absorb and retain water makes them effective barriers against humidity, which can otherwise lead to corrosion and malfunction of electronic devices. Similarly, in the semiconductor industry, hydrogel coatings are applied to protect delicate circuits and components from contamination and mechanical stress. The chemical industry also benefits from the unique properties of functional hydrogel coatings. These coatings are used to improve the efficiency of chemical reactions by providing a controlled environment for reactants. Their ability to swell and contract in response to changes in temperature or pH can be harnessed to regulate reaction rates and enhance product yield. Furthermore, in the machinery sector, hydrogel coatings are applied to reduce friction and wear on moving parts, thereby extending the lifespan of equipment and reducing maintenance costs. The versatility of functional hydrogel coatings makes them an invaluable tool across a wide range of applications, driving innovation and efficiency in both medical and non-medical fields. As research and development efforts continue to advance, the potential uses for these coatings are expected to expand, offering new solutions to complex challenges in various industries.

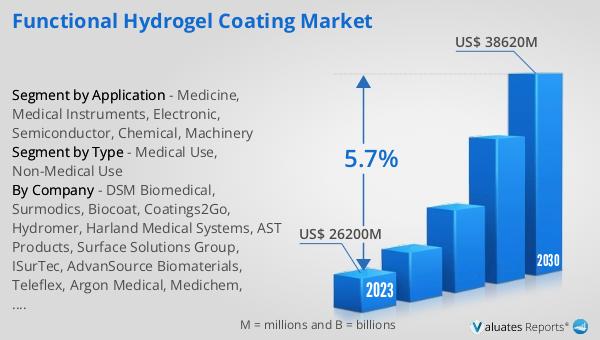

Global Functional Hydrogel Coating Market Outlook:

In 2024, the global market for Functional Hydrogel Coating was valued at approximately $29.11 billion. This market is anticipated to grow significantly, reaching an estimated value of $42.69 billion by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.7% over the forecast period. The increasing demand for functional hydrogel coatings across various industries, including medical, electronics, and chemical sectors, is a key driver of this market expansion. The unique properties of hydrogel coatings, such as their biocompatibility, flexibility, and ability to respond to environmental stimuli, make them highly desirable for enhancing product performance and longevity. As industries continue to seek innovative solutions to improve their products, the demand for functional hydrogel coatings is expected to rise. This growth presents new opportunities for manufacturers and researchers to develop more sophisticated and efficient hydrogel coatings that can address contemporary challenges across multiple fields. The versatility and adaptability of these coatings ensure their relevance in the advancement of modern technology and healthcare solutions, making them a crucial component in the global market landscape.

| Report Metric | Details |

| Report Name | Functional Hydrogel Coating Market |

| Accounted market size in year | US$ 29110 million |

| Forecasted market size in 2031 | US$ 42690 million |

| CAGR | 5.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | DSM Biomedical, Surmodics, Biocoat, Coatings2Go, Hydromer, Harland Medical Systems, AST Products, Surface Solutions Group, ISurTec, AdvanSource Biomaterials, Teleflex, Argon Medical, Medichem, JMedtech, 3M, Akzo Nobel, PPG Industries, SCHOTT, SOCOMORE |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |