What is Global Ceramic Substrate (Metallized) Market?

The Global Ceramic Substrate (Metallized) Market is a specialized segment within the broader electronics and materials industry, focusing on the production and application of ceramic substrates that have been metallized. These substrates are essential components in various electronic devices due to their excellent thermal conductivity, electrical insulation, and mechanical strength. Metallization involves coating the ceramic surface with a metal layer, which enhances its ability to conduct electricity and bond with other materials. This process is crucial for creating reliable and efficient electronic circuits, especially in high-performance applications. The market for these substrates is driven by the increasing demand for miniaturized and high-efficiency electronic devices across various sectors, including automotive, telecommunications, and consumer electronics. As technology advances, the need for substrates that can withstand higher temperatures and provide better performance continues to grow, making the Global Ceramic Substrate (Metallized) Market a vital area of focus for manufacturers and researchers alike. The market's growth is also fueled by the ongoing trend towards electrification and digitalization, which requires advanced materials capable of supporting complex electronic systems.

in the Global Ceramic Substrate (Metallized) Market:

The Global Ceramic Substrate (Metallized) Market encompasses a variety of types, each tailored to meet the specific needs of different customers and applications. One of the primary types is Alumina (Al2O3) substrates, which are widely used due to their excellent thermal and electrical properties. Alumina substrates are cost-effective and provide a good balance of performance and durability, making them suitable for a range of applications from consumer electronics to industrial equipment. Another important type is Aluminum Nitride (AlN) substrates, known for their superior thermal conductivity, which is crucial for high-power applications. AlN substrates are often used in power electronics and LED lighting, where efficient heat dissipation is critical. Beryllium Oxide (BeO) substrates, although less common due to their toxicity, offer exceptional thermal conductivity and are used in specialized applications where performance outweighs health concerns. Silicon Nitride (Si3N4) substrates are also gaining popularity, particularly in automotive and aerospace industries, due to their high strength and thermal shock resistance. These substrates are ideal for environments that experience rapid temperature changes and mechanical stress. Additionally, there are specialized substrates like Zirconia (ZrO2) and Silicon Carbide (SiC), which are used in niche applications requiring specific properties such as high fracture toughness or chemical resistance. The choice of substrate type depends largely on the application's requirements, including thermal management, electrical insulation, mechanical strength, and cost considerations. As technology evolves, the demand for advanced ceramic substrates with enhanced properties continues to rise, driving innovation and development within the market. Manufacturers are constantly exploring new materials and metallization techniques to improve the performance and reliability of ceramic substrates, ensuring they meet the ever-increasing demands of modern electronic devices. The diversity of substrate types available in the market allows customers to select the most appropriate material for their specific needs, whether it's for high-frequency communication devices, power modules, or consumer electronics. This variety not only supports the growth of the Global Ceramic Substrate (Metallized) Market but also fosters competition and innovation among manufacturers, leading to better products and solutions for end-users.

Automotive & EV/HEV Power Module, PV and Wind Power, Industrial Drives, Consumer & White Goods, LED, Rail Transport, Military & Avionics, Others in the Global Ceramic Substrate (Metallized) Market:

The Global Ceramic Substrate (Metallized) Market plays a crucial role in various industries, providing essential components for a wide range of applications. In the automotive and electric vehicle (EV) sectors, ceramic substrates are used in power modules to manage heat and improve the efficiency of electronic systems. These substrates help in reducing the size and weight of power modules, which is critical for the performance and range of EVs and hybrid electric vehicles (HEVs). In the renewable energy sector, ceramic substrates are used in photovoltaic (PV) and wind power systems to enhance the reliability and efficiency of power conversion and distribution. They provide the necessary thermal management and electrical insulation required for these high-power applications. In industrial drives, ceramic substrates are used to improve the performance and durability of motor control systems, ensuring efficient operation and reduced energy consumption. In the consumer electronics and white goods sectors, ceramic substrates are used in various devices to enhance performance and reliability. They are essential in LED lighting systems, where efficient heat dissipation is crucial for maintaining brightness and longevity. In rail transport, ceramic substrates are used in power electronics to ensure reliable operation under harsh conditions, such as vibration and temperature fluctuations. In the military and avionics sectors, ceramic substrates are used in advanced electronic systems that require high reliability and performance in extreme environments. These substrates provide the necessary thermal management and electrical insulation for critical applications, such as radar and communication systems. The versatility and performance of ceramic substrates make them indispensable in these industries, driving the growth and development of the Global Ceramic Substrate (Metallized) Market. As technology advances and the demand for high-performance electronic systems increases, the use of ceramic substrates is expected to expand further, supporting innovation and efficiency across various sectors.

Global Ceramic Substrate (Metallized) Market Outlook:

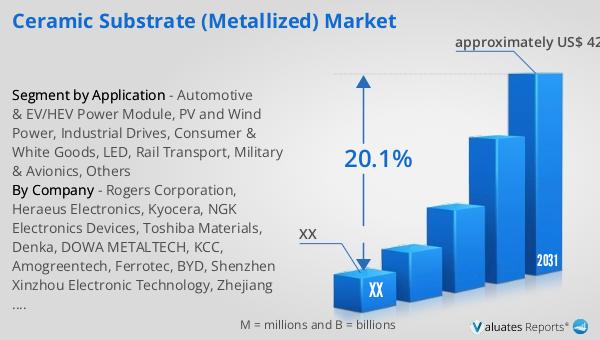

In 2024, the global market for Ceramic Substrate Metallized was valued at approximately USD 1,189 million. This market is projected to experience significant growth, with expectations to reach around USD 4,214 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 20.1% during the forecast period from 2025 to 2031. This impressive growth rate underscores the increasing demand for metallized ceramic substrates across various industries. The rising adoption of advanced electronic devices, coupled with the need for efficient thermal management solutions, is driving this market expansion. As industries continue to innovate and develop more sophisticated electronic systems, the demand for high-performance materials like metallized ceramic substrates is expected to rise. This market outlook highlights the potential for significant opportunities for manufacturers and suppliers in the Global Ceramic Substrate (Metallized) Market. The projected growth also reflects the broader trends of electrification and digitalization, which are reshaping industries and driving the need for advanced materials that can support complex electronic systems. As a result, the Global Ceramic Substrate (Metallized) Market is poised for substantial growth, offering promising prospects for stakeholders in the coming years.

| Report Metric | Details |

| Report Name | Ceramic Substrate (Metallized) Market |

| Forecasted market size in 2031 | approximately US$ 4214 million |

| CAGR | 20.1% |

| Forecasted years | 2025 - 2031 |

| Segment by Application |

|

| By Region |

|

| By Company | Rogers Corporation, Heraeus Electronics, Kyocera, NGK Electronics Devices, Toshiba Materials, Denka, DOWA METALTECH, KCC, Amogreentech, Ferrotec, BYD, Shenzhen Xinzhou Electronic Technology, Zhejiang TC Ceramic Electronic, Shengda Tech, Beijing Moshi Technology, Nantong Winspower, Wuxi Tianyang Electronics, Nanjing Zhongjiang New Material Science & Technology, Littelfuse IXYS, Remtec, Stellar Industries Corp, Tong Hsing (acquired HCS), Zibo Linzi Yinhe High-Tech Development, Chengdu Wanshida Ceramic Industry, Tong Hsing, ICP Technology, Ecocera, Tensky (Xellatech), Ceratron Electric, Wuhan Lizhida Technology, Folysky Technology(Wuhan), Zhuhai Hanci Jingmi, Meizhou Zhanzhi Electronic Technology, Huizhou Xinci Semiconductor, Yiyang Smuyang Electronic Technology, Shenzhen Yuan Xuci Electronic Technology, SinoVio Semiconductor Technol, Suzhou GYZ Electronic Technology, Segment by Material, DBC Ceramic Substrate, DPC Ceramic Substrate, AMB Ceramic Substrate, Others |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |