What is Global Medical Grade Rubber Market?

The Global Medical Grade Rubber Market is a specialized segment within the broader rubber industry, focusing on the production and supply of rubber materials that meet stringent medical standards. These rubbers are used in various medical applications due to their unique properties, such as biocompatibility, flexibility, and resistance to chemicals and extreme temperatures. Medical grade rubber is essential in manufacturing a wide range of medical devices and components, including seals, gaskets, diaphragms, and tubing. The demand for these materials is driven by the growing healthcare industry, advancements in medical technology, and the increasing need for safe and reliable medical devices. As healthcare systems worldwide continue to expand and modernize, the market for medical grade rubber is expected to grow, offering opportunities for manufacturers and suppliers to innovate and meet the evolving needs of the medical sector. The market is characterized by a focus on quality, compliance with regulatory standards, and the development of new formulations to enhance performance and safety.

Silicone Rubber, Fluororubber in the Global Medical Grade Rubber Market:

Silicone rubber and fluororubber are two prominent types of materials used in the Global Medical Grade Rubber Market, each offering distinct advantages for medical applications. Silicone rubber is renowned for its excellent biocompatibility, making it ideal for use in medical devices that come into direct contact with the human body. Its flexibility, durability, and resistance to extreme temperatures and environmental conditions make it a preferred choice for a wide range of applications, including catheters, seals, and gaskets. Silicone rubber is also hypoallergenic, reducing the risk of adverse reactions in patients. Additionally, its transparency allows for easy inspection and monitoring of fluids in medical tubing. On the other hand, fluororubber, also known as fluoroelastomer, is valued for its exceptional chemical resistance and stability under harsh conditions. This makes it suitable for applications where exposure to aggressive chemicals or high temperatures is a concern, such as in seals and gaskets used in medical equipment and devices. Fluororubber's resistance to degradation ensures the longevity and reliability of medical components, even in demanding environments. Both silicone rubber and fluororubber are subject to rigorous testing and certification processes to ensure they meet the stringent standards required for medical applications. Manufacturers in the Global Medical Grade Rubber Market are continually innovating to enhance the properties of these materials, developing new formulations that offer improved performance, safety, and sustainability. This includes efforts to reduce the environmental impact of production processes and to create materials that are easier to recycle or dispose of safely. As the demand for advanced medical devices continues to grow, the role of silicone rubber and fluororubber in the medical industry is expected to expand, driven by their unique properties and the ongoing need for high-quality, reliable materials. The Global Medical Grade Rubber Market is a dynamic and evolving sector, with manufacturers and suppliers working closely with healthcare providers and regulatory bodies to ensure that their products meet the highest standards of safety and performance. This collaboration is essential to address the challenges and opportunities presented by the rapidly changing landscape of the healthcare industry, where innovation and quality are paramount.

Hospital, Clinic, Others in the Global Medical Grade Rubber Market:

The usage of Global Medical Grade Rubber Market materials in hospitals, clinics, and other healthcare settings is extensive and varied, reflecting the critical role these materials play in ensuring the safety and effectiveness of medical devices and equipment. In hospitals, medical grade rubber is used in a wide range of applications, from surgical instruments and diagnostic equipment to patient care products and facility maintenance. For example, silicone rubber is commonly used in the production of catheters, seals, and gaskets, where its biocompatibility and flexibility are essential for patient safety and comfort. Fluororubber, with its chemical resistance and durability, is often used in seals and gaskets for medical equipment that must withstand harsh cleaning agents and sterilization processes. In clinics, medical grade rubber materials are used in various diagnostic and therapeutic devices, such as blood pressure cuffs, respiratory masks, and infusion pumps. The reliability and performance of these devices are crucial for accurate diagnosis and effective treatment, making the choice of materials a critical consideration for healthcare providers. The use of medical grade rubber in these applications ensures that devices are safe, durable, and capable of withstanding the rigors of daily use in a clinical setting. Beyond hospitals and clinics, medical grade rubber is also used in other healthcare settings, such as laboratories, research facilities, and home healthcare environments. In laboratories, rubber materials are used in the production of equipment and instruments that require precise control and measurement, such as pipettes, syringes, and tubing. The chemical resistance and stability of fluororubber make it an ideal choice for these applications, where exposure to aggressive chemicals and extreme temperatures is common. In home healthcare settings, medical grade rubber is used in products such as mobility aids, orthopedic supports, and personal care items, where comfort, safety, and ease of use are paramount. The versatility and adaptability of medical grade rubber materials make them an essential component of the healthcare industry, supporting the delivery of high-quality care across a wide range of settings and applications. As the demand for advanced medical devices and equipment continues to grow, the role of medical grade rubber in the healthcare industry is expected to expand, driven by the need for safe, reliable, and innovative materials that meet the evolving needs of patients and healthcare providers.

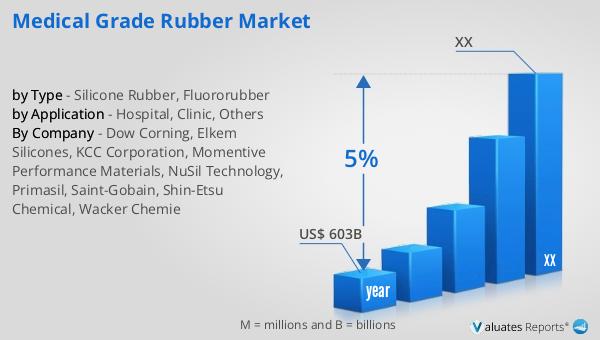

Global Medical Grade Rubber Market Outlook:

Based on our research, the global market for medical devices is projected to reach approximately $603 billion in 2023, with an anticipated growth rate of 5% annually over the next six years. This growth is indicative of the increasing demand for medical devices worldwide, driven by factors such as technological advancements, an aging population, and the rising prevalence of chronic diseases. The expansion of healthcare infrastructure in emerging markets and the growing emphasis on improving patient outcomes are also contributing to the robust growth of the medical device market. As the market continues to evolve, manufacturers and suppliers are focusing on innovation and quality to meet the diverse needs of healthcare providers and patients. This includes the development of new materials and technologies that enhance the performance, safety, and sustainability of medical devices. The Global Medical Grade Rubber Market plays a crucial role in this landscape, providing essential materials that meet the stringent standards required for medical applications. As the demand for advanced medical devices continues to grow, the market for medical grade rubber is expected to expand, offering opportunities for manufacturers and suppliers to innovate and meet the evolving needs of the medical sector. The focus on quality, compliance with regulatory standards, and the development of new formulations to enhance performance and safety are key drivers of growth in the Global Medical Grade Rubber Market.

| Report Metric | Details |

| Report Name | Medical Grade Rubber Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Dow Corning, Elkem Silicones, KCC Corporation, Momentive Performance Materials, NuSil Technology, Primasil, Saint-Gobain, Shin-Etsu Chemical, Wacker Chemie |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |