What is Global Aluminum Plastic Film for 3C Electronics Market?

The Global Aluminum Plastic Film for 3C Electronics Market is a specialized segment within the broader electronics industry, focusing on the use of aluminum plastic films in 3C (Computer, Communication, and Consumer Electronics) devices. These films are crucial components in the manufacturing of lithium-ion batteries, which power a wide range of electronic devices. The aluminum plastic film acts as a protective layer, ensuring the safety and efficiency of the battery by providing excellent insulation and resistance to external factors such as moisture and temperature fluctuations. This market is driven by the increasing demand for portable electronic devices, which require reliable and efficient power sources. As technology advances, the need for high-performance batteries grows, thereby boosting the demand for aluminum plastic films. The market is characterized by continuous innovation, with manufacturers striving to develop films that offer better performance, durability, and cost-effectiveness. The growth of this market is also influenced by the rising trend of miniaturization in electronics, which necessitates the use of compact and lightweight materials like aluminum plastic films. Overall, the Global Aluminum Plastic Film for 3C Electronics Market plays a vital role in the advancement of modern electronic devices, supporting their functionality and longevity.

88μm, 113μm, Others in the Global Aluminum Plastic Film for 3C Electronics Market:

In the Global Aluminum Plastic Film for 3C Electronics Market, different thicknesses of films such as 88μm, 113μm, and others are used to cater to various applications and performance requirements. The 88μm aluminum plastic film is typically used in applications where flexibility and lightweight properties are prioritized. This thickness is ideal for devices that require compact and efficient battery solutions, such as smartphones and wearable devices. The thinness of the 88μm film allows for better heat dissipation and contributes to the overall reduction in the weight of the device, which is a critical factor in portable electronics. On the other hand, the 113μm aluminum plastic film is preferred in applications where enhanced durability and protection are necessary. This thickness provides a more robust barrier against external elements, making it suitable for devices that are exposed to harsher environments or require longer battery life. The 113μm film is often used in laptops and other larger electronic devices where the battery needs to withstand more demanding conditions. Additionally, there are other thicknesses available in the market, each designed to meet specific needs and preferences of manufacturers and consumers. These variations allow for customization and optimization of battery performance across different types of 3C electronics. The choice of film thickness is influenced by factors such as the device's intended use, size constraints, and the desired balance between weight and durability. Manufacturers in the Global Aluminum Plastic Film for 3C Electronics Market continuously explore new materials and technologies to enhance the properties of these films, aiming to improve their thermal stability, mechanical strength, and overall efficiency. This ongoing innovation is crucial in meeting the evolving demands of the electronics industry, where devices are becoming increasingly sophisticated and multifunctional. As the market expands, the availability of diverse film thicknesses ensures that manufacturers can select the most appropriate solution for their specific applications, ultimately contributing to the advancement of electronic devices and their capabilities.

Smartphones, Laptops, Wearable Devices, Others in the Global Aluminum Plastic Film for 3C Electronics Market:

The usage of Global Aluminum Plastic Film for 3C Electronics Market extends across various areas, including smartphones, laptops, wearable devices, and others, each benefiting from the unique properties of these films. In smartphones, aluminum plastic films are integral to the construction of lithium-ion batteries, which are the primary power source for these devices. The films provide essential protection against external factors such as moisture and temperature changes, ensuring the safety and longevity of the battery. This is particularly important in smartphones, where battery performance directly impacts the device's overall functionality and user experience. The lightweight and flexible nature of aluminum plastic films also contribute to the slim and sleek design of modern smartphones, which is a key selling point for consumers. In laptops, aluminum plastic films are used to enhance the durability and efficiency of the batteries. Laptops require batteries that can withstand prolonged usage and provide consistent power output, making the robust properties of aluminum plastic films highly valuable. The films help maintain the battery's structural integrity, preventing damage from external elements and ensuring reliable performance over time. This is crucial for laptops, which are often used in various environments and for extended periods. Wearable devices, such as smartwatches and fitness trackers, also benefit from the use of aluminum plastic films. These devices demand compact and lightweight batteries that can deliver sufficient power without adding bulk. The thin and flexible nature of aluminum plastic films makes them ideal for use in wearable technology, where space is limited, and comfort is a priority. The films enable the creation of small yet powerful batteries that can support the advanced features of wearable devices, such as health monitoring and connectivity. Beyond these specific applications, aluminum plastic films are used in a wide range of other electronic devices, including tablets, cameras, and portable gaming consoles. In each case, the films provide critical protection and performance benefits, supporting the functionality and reliability of the device. As the demand for portable and efficient electronic devices continues to grow, the role of aluminum plastic films in the 3C Electronics Market becomes increasingly important. Their ability to enhance battery performance and contribute to the overall design and usability of electronic devices makes them a vital component in the advancement of modern technology.

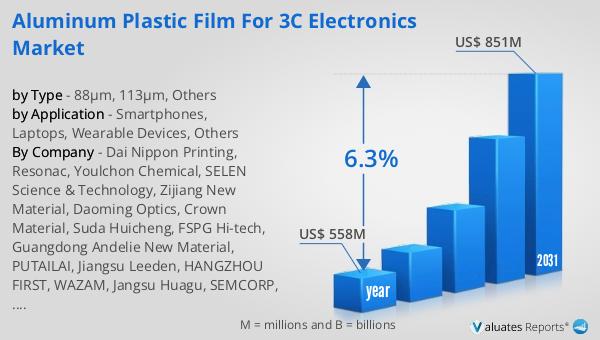

Global Aluminum Plastic Film for 3C Electronics Market Outlook:

The global market for Aluminum Plastic Film for 3C Electronics was valued at $558 million in 2024 and is anticipated to grow significantly, reaching an estimated size of $851 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.3% over the forecast period. This upward trend is indicative of the increasing demand for aluminum plastic films, driven by the expanding market for 3C electronics, which includes computers, communication devices, and consumer electronics. The growth is fueled by the rising adoption of portable electronic devices, which require efficient and reliable power sources. As technology continues to evolve, the need for high-performance batteries becomes more pronounced, further boosting the demand for aluminum plastic films. The market's expansion is also supported by ongoing innovations in film technology, aimed at enhancing the performance, durability, and cost-effectiveness of these materials. Manufacturers are continuously exploring new materials and production techniques to meet the evolving needs of the electronics industry. The projected growth of the Global Aluminum Plastic Film for 3C Electronics Market underscores the critical role these films play in the advancement of modern electronic devices, supporting their functionality, efficiency, and longevity. As the market continues to grow, it presents significant opportunities for manufacturers and stakeholders to capitalize on the increasing demand for high-quality aluminum plastic films.

| Report Metric | Details |

| Report Name | Aluminum Plastic Film for 3C Electronics Market |

| Accounted market size in year | US$ 558 million |

| Forecasted market size in 2031 | US$ 851 million |

| CAGR | 6.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Dai Nippon Printing, Resonac, Youlchon Chemical, SELEN Science & Technology, Zijiang New Material, Daoming Optics, Crown Material, Suda Huicheng, FSPG Hi-tech, Guangdong Andelie New Material, PUTAILAI, Jiangsu Leeden, HANGZHOU FIRST, WAZAM, Jangsu Huagu, SEMCORP, Tonytech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |