What is Global High Thermal Conductivity Die Attach Film Market?

The Global High Thermal Conductivity Die Attach Film Market is a specialized segment within the broader electronics and semiconductor industry. This market focuses on films that are used to attach semiconductor dies to substrates or packages, ensuring efficient heat dissipation. These films are crucial in maintaining the performance and reliability of electronic devices by managing the heat generated during operation. High thermal conductivity die attach films are designed to offer superior thermal management, which is essential for high-performance applications such as power electronics, LEDs, and advanced computing systems. The demand for these films is driven by the increasing complexity and miniaturization of electronic components, which require effective thermal management solutions to prevent overheating and ensure longevity. As technology continues to advance, the need for efficient thermal management solutions like high thermal conductivity die attach films is expected to grow, making this market an important area of focus for manufacturers and researchers alike.

Electro-conductive Film, Non Electro-conductive Film in the Global High Thermal Conductivity Die Attach Film Market:

Electro-conductive films and non-electro-conductive films are two primary categories within the Global High Thermal Conductivity Die Attach Film Market, each serving distinct purposes based on their conductive properties. Electro-conductive films are designed to conduct electricity, making them ideal for applications where electrical connectivity is required alongside thermal management. These films are often used in semiconductor devices where electrical pathways need to be established between the die and the substrate. The electro-conductive nature of these films ensures that they can efficiently transfer both heat and electrical signals, which is crucial for the performance of high-frequency and high-power devices. On the other hand, non-electro-conductive films are used in applications where electrical insulation is necessary. These films provide excellent thermal conductivity while preventing electrical currents from passing through, making them suitable for devices where electrical isolation is critical. Non-electro-conductive films are often used in applications such as LED packaging and other electronic components where thermal management is needed without compromising electrical insulation. The choice between electro-conductive and non-electro-conductive films depends on the specific requirements of the application, including the need for electrical connectivity or insulation, thermal management, and the operating environment of the device. Both types of films play a crucial role in the performance and reliability of electronic devices, and their development is driven by the ongoing advancements in semiconductor technology and the increasing demand for high-performance electronic components. As the electronics industry continues to evolve, the need for specialized die attach films that can meet the diverse requirements of modern electronic devices is expected to grow, making this market an important area of focus for manufacturers and researchers alike.

SMT Assembly, Semiconductor Packaging, Others in the Global High Thermal Conductivity Die Attach Film Market:

The Global High Thermal Conductivity Die Attach Film Market finds its usage in several key areas, including Surface Mount Technology (SMT) Assembly, Semiconductor Packaging, and other applications. In SMT Assembly, these films are used to attach semiconductor dies to printed circuit boards (PCBs), ensuring efficient heat dissipation and reliable electrical connections. The high thermal conductivity of these films helps in managing the heat generated by electronic components during operation, preventing overheating and ensuring the longevity of the devices. In Semiconductor Packaging, die attach films play a crucial role in securing the semiconductor die to the package, providing both thermal management and mechanical stability. The films ensure that the heat generated by the semiconductor is efficiently dissipated, which is essential for maintaining the performance and reliability of the device. Additionally, these films provide mechanical support, protecting the die from physical damage and ensuring its proper alignment within the package. Other applications of high thermal conductivity die attach films include their use in power electronics, LEDs, and advanced computing systems, where efficient thermal management is critical for optimal performance. These films help in managing the heat generated by high-power devices, ensuring that they operate within safe temperature limits and maintain their performance over time. The versatility and effectiveness of high thermal conductivity die attach films make them an essential component in a wide range of electronic applications, and their demand is expected to grow as the electronics industry continues to advance.

Global High Thermal Conductivity Die Attach Film Market Outlook:

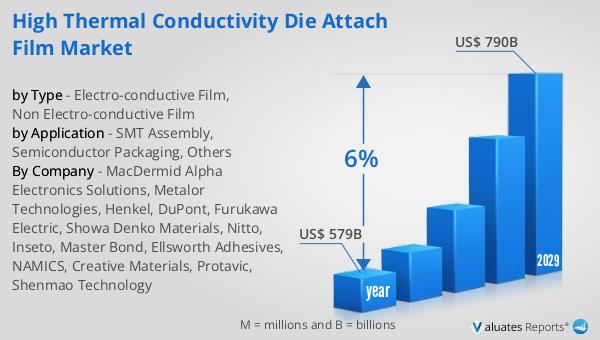

The global semiconductor market, which was valued at approximately $579 billion in 2022, is anticipated to reach around $790 billion by 2029, reflecting a compound annual growth rate (CAGR) of 6% over the forecast period. This growth is indicative of the increasing demand for semiconductors across various industries, driven by advancements in technology and the proliferation of electronic devices. The semiconductor industry is a critical component of the global economy, providing the essential building blocks for a wide range of electronic products, from consumer electronics to industrial machinery. The projected growth in the semiconductor market is expected to have a significant impact on related markets, including the Global High Thermal Conductivity Die Attach Film Market, as the demand for efficient thermal management solutions continues to rise. As electronic devices become more complex and powerful, the need for advanced materials that can effectively manage heat and ensure the reliability of these devices becomes increasingly important. The growth of the semiconductor market is likely to drive innovation and development in the die attach film market, as manufacturers seek to meet the evolving needs of the electronics industry.

| Report Metric | Details |

| Report Name | High Thermal Conductivity Die Attach Film Market |

| Accounted market size in year | US$ 579 billion |

| Forecasted market size in 2029 | US$ 790 billion |

| CAGR | 6% |

| Base Year | year |

| Forecasted years | 2025 - 2029 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | MacDermid Alpha Electronics Solutions, Metalor Technologies, Henkel, DuPont, Furukawa Electric, Showa Denko Materials, Nitto, Inseto, Master Bond, Ellsworth Adhesives, NAMICS, Creative Materials, Protavic, Shenmao Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |