What is Global Conductive Die Attach Paste Market?

The Global Conductive Die Attach Paste Market is a specialized segment within the broader electronics and semiconductor industry. This market focuses on the production and distribution of conductive die attach pastes, which are essential materials used in the assembly of electronic components. These pastes are primarily used to attach semiconductor chips to substrates or packages, ensuring both mechanical stability and electrical conductivity. The demand for these pastes is driven by the increasing miniaturization of electronic devices, the growing complexity of semiconductor packaging, and the need for reliable thermal management solutions. As electronic devices become more compact and powerful, the role of conductive die attach pastes becomes even more critical, as they help in dissipating heat and maintaining the performance of the device. The market is characterized by continuous innovation, with manufacturers focusing on developing pastes that offer better thermal conductivity, lower voiding, and improved reliability. Additionally, environmental regulations and the push for lead-free and halogen-free materials are influencing the development of new formulations. Overall, the Global Conductive Die Attach Paste Market is poised for growth, driven by advancements in electronics and the ever-increasing demand for high-performance, reliable electronic devices.

No-clean Pastes, Rosin-based Pastes, Water Soluble Pastes, Others in the Global Conductive Die Attach Paste Market:

In the Global Conductive Die Attach Paste Market, different types of pastes are used, each with its unique properties and applications. No-clean pastes are one of the most popular types, known for their convenience and efficiency. These pastes do not require cleaning after the soldering process, which saves time and reduces costs. They are formulated to leave minimal residues that are non-corrosive and non-conductive, making them ideal for applications where cleaning is impractical or impossible. No-clean pastes are widely used in consumer electronics, automotive electronics, and telecommunications due to their reliability and ease of use. Rosin-based pastes, on the other hand, are traditional solder pastes that contain rosin, a natural resin obtained from pine trees. These pastes are known for their excellent wetting properties and ability to form strong, reliable joints. However, they require cleaning after the soldering process to remove the rosin residues, which can be corrosive over time. Rosin-based pastes are often used in applications where high-reliability joints are required, such as in aerospace and military electronics. Water-soluble pastes are another type of conductive die attach paste that is gaining popularity. These pastes are designed to be easily cleaned with water, making them an environmentally friendly option. They are ideal for applications where post-soldering cleaning is necessary, such as in medical devices and high-reliability electronics. Water-soluble pastes offer excellent solderability and leave minimal residues, ensuring high-quality joints. Other types of pastes in the market include hybrid pastes, which combine the properties of different paste types to offer enhanced performance. These pastes are designed to meet specific application requirements, such as high thermal conductivity or low voiding. The choice of paste type depends on various factors, including the application, the required performance characteristics, and environmental considerations. As the demand for advanced electronic devices continues to grow, the Global Conductive Die Attach Paste Market is expected to see increased innovation and development of new paste formulations to meet the evolving needs of the industry.

SMT Assembly, Semiconductor Packaging, Others in the Global Conductive Die Attach Paste Market:

The Global Conductive Die Attach Paste Market plays a crucial role in various applications, including Surface Mount Technology (SMT) Assembly, Semiconductor Packaging, and other areas. In SMT Assembly, conductive die attach pastes are used to attach semiconductor chips to printed circuit boards (PCBs). This process is essential for the production of compact and efficient electronic devices, as it ensures both mechanical stability and electrical connectivity. The use of conductive die attach pastes in SMT Assembly helps in achieving high-density interconnections, which are critical for modern electronic devices. These pastes also aid in thermal management, ensuring that the heat generated by the components is effectively dissipated, thus enhancing the reliability and performance of the device. In Semiconductor Packaging, conductive die attach pastes are used to attach semiconductor chips to their respective packages. This process is vital for protecting the chips from environmental factors and ensuring their proper functioning. The pastes provide a strong bond between the chip and the package, ensuring mechanical stability and electrical conductivity. They also play a crucial role in thermal management, helping to dissipate heat generated by the chip and preventing overheating. The use of conductive die attach pastes in semiconductor packaging is essential for the production of high-performance, reliable semiconductor devices. In addition to SMT Assembly and Semiconductor Packaging, conductive die attach pastes are used in various other applications, including LED assembly, power electronics, and automotive electronics. In LED assembly, these pastes are used to attach LED chips to substrates, ensuring efficient heat dissipation and reliable electrical connections. In power electronics, conductive die attach pastes are used to attach power semiconductor devices to heat sinks, ensuring effective thermal management and reliable performance. In automotive electronics, these pastes are used in various applications, including engine control units, infotainment systems, and advanced driver-assistance systems (ADAS), where reliable electrical connections and effective thermal management are critical. Overall, the Global Conductive Die Attach Paste Market is essential for the production of high-performance, reliable electronic devices across various industries.

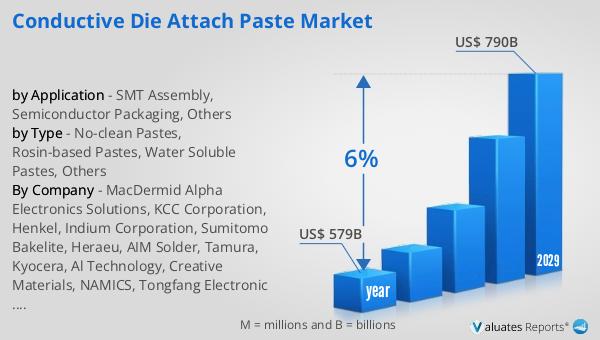

Global Conductive Die Attach Paste Market Outlook:

The semiconductor industry is experiencing significant growth, with the global market valued at approximately $579 billion in 2022. This market is projected to reach around $790 billion by 2029, reflecting a compound annual growth rate (CAGR) of 6% over the forecast period. This growth is driven by several factors, including the increasing demand for electronic devices, advancements in technology, and the growing adoption of semiconductors in various industries such as automotive, telecommunications, and consumer electronics. The rise of technologies such as 5G, artificial intelligence, and the Internet of Things (IoT) is also contributing to the expansion of the semiconductor market. As these technologies become more prevalent, the demand for advanced semiconductor components is expected to increase, driving the growth of the market. Additionally, the trend towards miniaturization and the development of more powerful and efficient electronic devices are further fueling the demand for semiconductors. The growth of the semiconductor market is also supported by investments in research and development, as companies strive to develop innovative solutions to meet the evolving needs of the industry. As the market continues to expand, the Global Conductive Die Attach Paste Market is expected to benefit from the increasing demand for high-performance, reliable electronic components.

| Report Metric | Details |

| Report Name | Conductive Die Attach Paste Market |

| Accounted market size in year | US$ 579 billion |

| Forecasted market size in 2029 | US$ 790 billion |

| CAGR | 6% |

| Base Year | year |

| Forecasted years | 2025 - 2029 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | MacDermid Alpha Electronics Solutions, KCC Corporation, Henkel, Indium Corporation, Sumitomo Bakelite, Heraeu, AIM Solder, Tamura, Kyocera, Al Technology, Creative Materials, NAMICS, Tongfang Electronic New Material, Shenmao Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |